AERCO BMK 6000 Dual Fuel User Manual

Page 82

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 6 – SAFETY DEVICE TESTING

Page 82 of 219

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0096_0B

03/21/2014

Ph.: 800-526-0288

GF-141

Low Gas Pressure Fault Test – Continued

5.

Remove the cover from the Low Gas Pressure Switch and set the dial indicator to 2 (the

minimum).

6.

Open the external gas supply ball valve upstream of the unit.

7.

Place the unit in Manual Mode and adjust the Air/Fuel Valve position (% open) to 100%.

8.

While the unit is firing, slowly decrease the incoming gas supply pressure while reading the

CO value on the combustion analyzer until the CO reading is approximately 300 ppm.

9.

Take a reading of the inlet gas pressure. If the inlet pressure is below the minimum

calculated in step 4, above, then increase the pressure to match the calculated minimum.

10.

Slowly turn the indicator dial on the Low Gas Pressure Switch until the unit shuts down due

to a gas pressure fault.

11.

Readjust the inlet gas pressure to what it was prior to the test.

12.

Press the CLEAR button on the Control Panel to clear the fault.

13.

The fault message should clear and the FAULT indicator should go off. The unit should

now restart.

14.

Repeat the previous procedure on the PROPANE gas train, starting with the 1/4“ plug next

to the PROPANE Low Gas Pressure switch, shown in the bottom-half of Figure 6-1A.

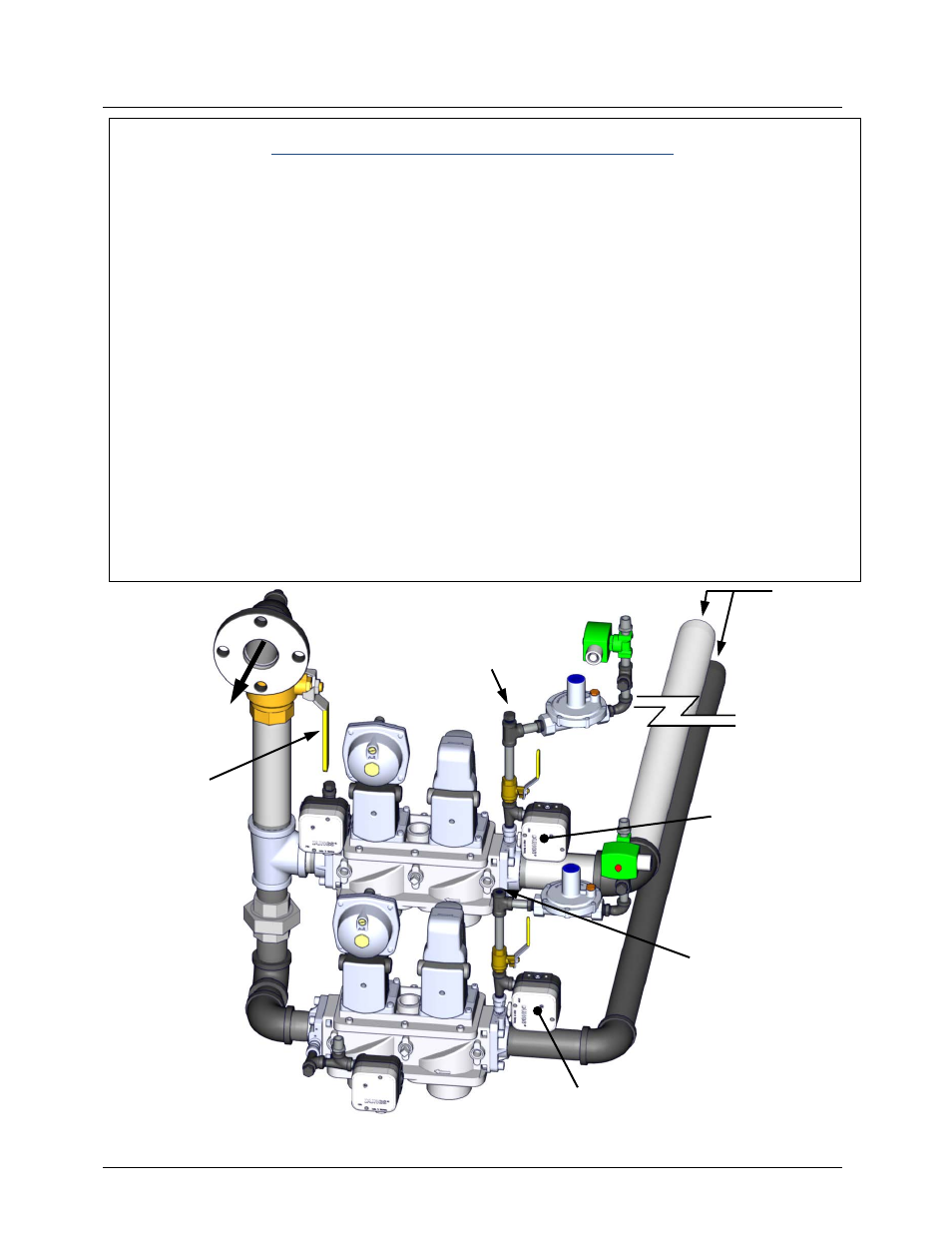

Figure 6-1A:

Low Gas Pressure Switch Locations & Test Point Locations

PROPANE LOW GAS PRESSURE SWITCH

(5.8” W.C.)

NATURAL GAS

LOW GAS

PRESSURE SWITCH

(8.5” W.C.)

NATURAL GAS

TEE with 1/4" PLUG (Install

manometer here for LOW

GAS PRESSURE test)

GAS

INLETS

MANUAL

SHUT-OFF

VALVE

TO AIR/FUEL

VALVE

PROPANE

TEE with 1/4" PLUG

(Install manometer

here for LOW GAS

PRESSURE test)