2 pressure/temperature gauge installation – AERCO BMK 6000 Dual Fuel User Manual

Page 21

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

OMM-0096_0B

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 21 of 219

GF-141

Ph.: 800-526-0288

03/21/2014

connections. Any excess should be wiped off to avoid getting any joint compound into the valve

body. Each relief valve must be piped to within 12 inches of the floor to prevent injury in the

event of a discharge. The discharge piping must be full size, without reduction. No valve or size

reductions are allowed in the discharge line. In multiple unit installations the discharge lines must

not be manifolded together. Each must be individually run to a suitable discharge location.

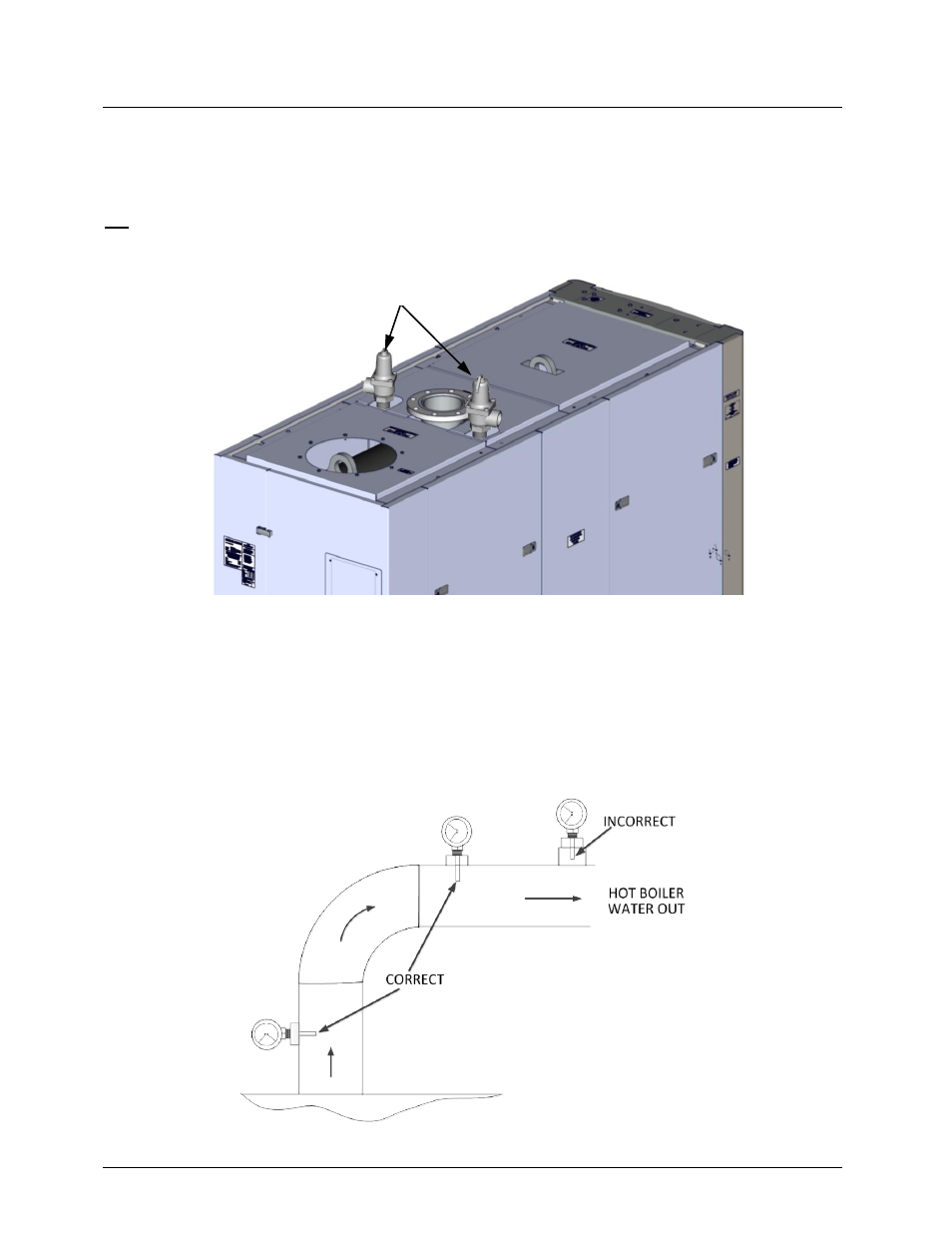

Figure 2-5A. Pressure Relief Valve Installation Locations

2.6.2 Pressure/Temperature Gauge Installation

A manual Pressure/Temperature Gauge is included in the loose parts kit for installation for

installation in the boiler outlet piping. It must be installed so that the sensing bulb is inserted into

the hot water outlet flow from the boiler. Refer to Figure 2-5B for sample installations.

Figure 2-5B. Pressure/Temperature Gauge Installation Location

PRESSURE RELIEF

VALVES