5 supply and return piping, 1 pressure relief valve installation – AERCO BMK 6000 Dual Fuel User Manual

Page 20

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

Page 20 of 219

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0096_0B

03/21/2014

Ph.: 800-526-0288

GF-141

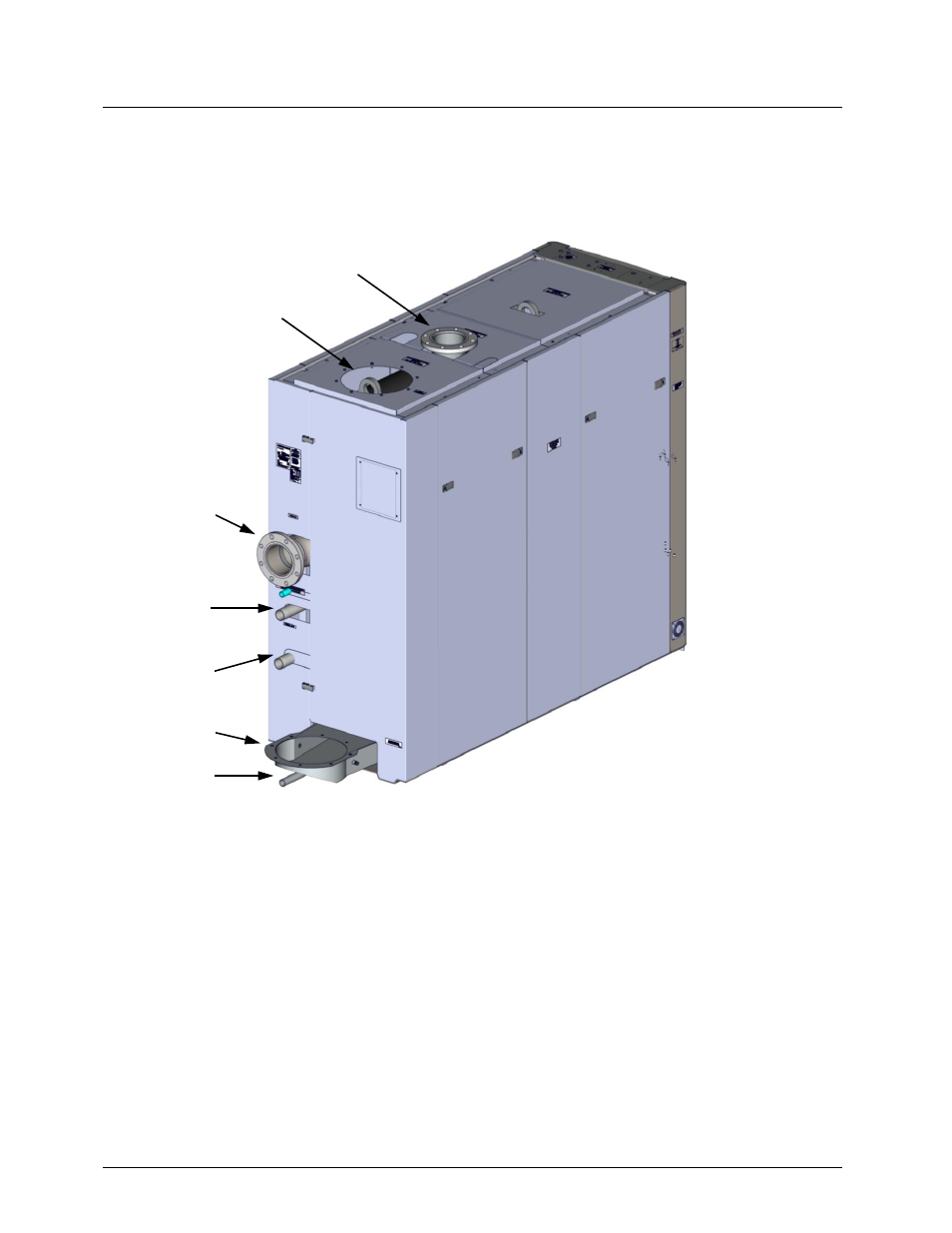

2.5 SUPPLY AND RETURN PIPING

The Benchmark boiler utilizes 6” flanged fittings for the water system supply and return piping

connections. The physical location of the supply and return piping connections are shown in

Figure 2-4. For dimensional data, refer to Drawing AP-A-901 in Appendix F.

Figure 2-4. Supply and Return Locations

2.6 PRESSURE RELIEF VALVE & PRESSURE/TEMPERATURE INDICATOR

INSTALLATION

2.6.1 Pressure Relief Valve Installation

Depending on the pressure required, the Benchmark 6000 is supplied with either a single 2” or

two (2) 1¼“ ASME rated Pressure Relief Valves. The pressure rating for the relief valve must be

specified on the sales order. Available pressure ratings range from 30 psi to 160 psi, depending

on pressure vessel maximum rated pressure. Each pressure relief valve is furnished as a kit

(92102-Tab) which consists of the relief valve for the pressure rating specified on the Sales

Order. The appropriate size reducing bushing and nipple are also included in the kit. The

pressure relief valves, nipples and bushings are connected to 45º street elbows already installed

on the heat exchanger of the boiler. The relief valves are installed on the top of the boiler as

shown in Figure 2-5A. A suitable pipe joint compound should be used on all threaded

6” WATER

OUTLET

AIR INLET

6” WATER

INLET

2” NATURAL

GAS INLET

EXHAUST

MANIFOLD

CONDENSATE

DRAIN

2” PROPANE

INLET