8 refractory removal & replacement – AERCO BMK 6000 Dual Fuel User Manual

Page 108

Benchmark 6000 DF Installation, Operation & Maintenance Manual

CHAPTER 7 – MAINTENANCE

Page 108 of 219

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0096_0B

03/21/2014

Ph.: 800-526-0288

GF-141

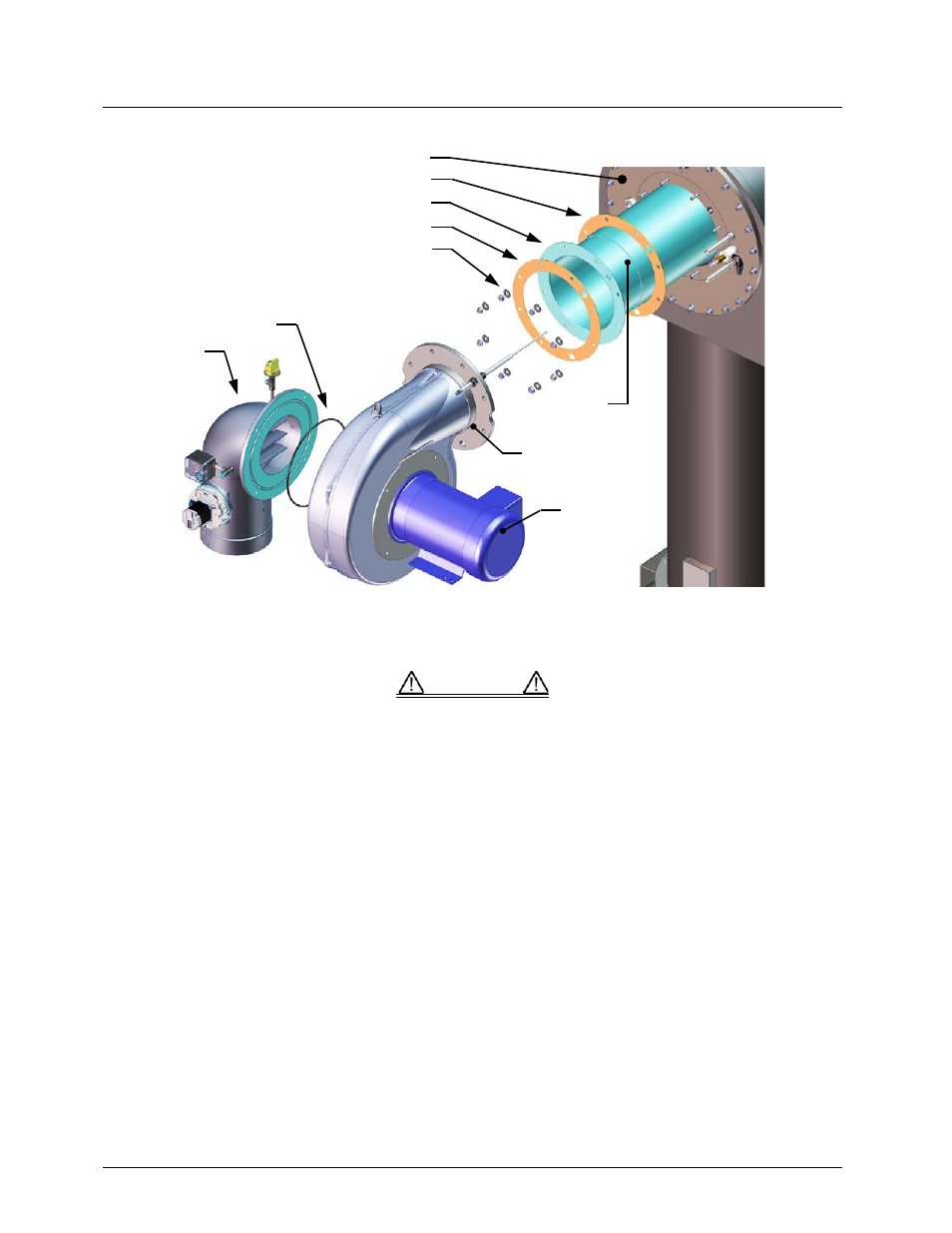

Figure 7-5: Air/Fuel Valve, Blower & Burner Assembly – Exploded View

THE HEAT EXCHANGER INSULATION UTILIZES CERAMIC FIBER

MATERIAL. WEAR A FITTED NIOSH-APPROVED PARTICULATE

RESPIRATOR (3M N95 OR EQUIV.) WHEN SERVICING THE HEAT

EXCHANGER AND BURNER ASSEMBLIES. AT HIGH TEMPERATURES,

CERAMIC FIBERS CAN BE CONVERTED TO CRYSTALINE SILICA

FIBERS WHICH HAVE BEEN IDENTIFIED AS CARCINOGENIC WHEN

INHALED.

7.8 REFRACTORY REMOVAL & REPLACEMENT

Low mass, fiber-based material insulates the front and rear end plates of the combustion

chamber. This material has very low thermal conductivity and is not susceptible to thermal shock

conditions that cause failures of hard-faced refractory materials.

In the event that access to the unit’s combustion chamber is required, the preferred method is to

remove the rear refractory first, since it requires fewer and less complicated procedural steps.

However, if the front refractory is removed first, the complete Burner assembly, blower assembly

and air/fuel valve assembly must be removed to access the refractory material.

The procedures for removal of the rear refractory and front refractory materials are provided in

sections 7.8.1 and 7.8.2, respectively.

WARNING

AIR/FUEL

VALVE

O-RING

BLOWER FLANGE

BLOWER

3/8” HEX NUTS/WASHERS (8 EA.)

BURNER GASKET (P/N 81159)

BURNER FLANGE

BURNER GASKET (P/N 81159)

BURNER

BURNER FRONT PLATE