0 setpoints, 1 batch and continuous setpoints, Setpoints – Rice Lake 520 HMI Digital Weight Indicator Installation Manual User Manual

Page 71

65

520 Indicator Installation Manual

11.0

Setpoints

The

520

indicator provides eight configurable setpoints for control of both indicator and external equipment

functions. Setpoints are configured to trip based on specified conditions; tripping the setpoint can be used to

request indicator functions (print, tare, accumulate) or to change the state of a digital output controlling external

equipment.

11.1

Batch and Continuous Setpoints

520

setpoints can be either continuous or batch setpoints.

Continuous setpoints

are free-running: the indicator constantly checks the input channel for the setpoint value

at each A/D update. If the input channel weight reading matches the setpoint value, the indicator sets the

corresponding digital output on.

Batch setpoints

are active one at a time, in an ordered sequence. The

520

can use batch setpoints to control up

to eight separate batch processing steps. A digital output associated with a batch setpoint is on until the setpoint

condition is met, then latched for the remainder of the batch sequence.

To use batch setpoints, you must activate the BATCHNG parameter on the SETPTS menu. This parameter defines

whether a batch sequence is automatic or manual. AUTO sequences repeat continuously, while MANUAL

sequences require a BATSTRT digital input or BATSTART EDP command before restarting. As shown in

Table 11-1 on page 65, GROSSSP, NETSP, and RELSP setpoint kinds can be configured as either batch or

continuous setpoints.

Note

If the checkweigh function is enabled, setpoints remain configured but do not function until checkweigh is

disabled.

The BATCH parameter must also be set on for each batch setpoint. If the setpoint is defined but the BATCH

parameter is off, the setpoint operates as a continuous setpoint, even during batch sequences.

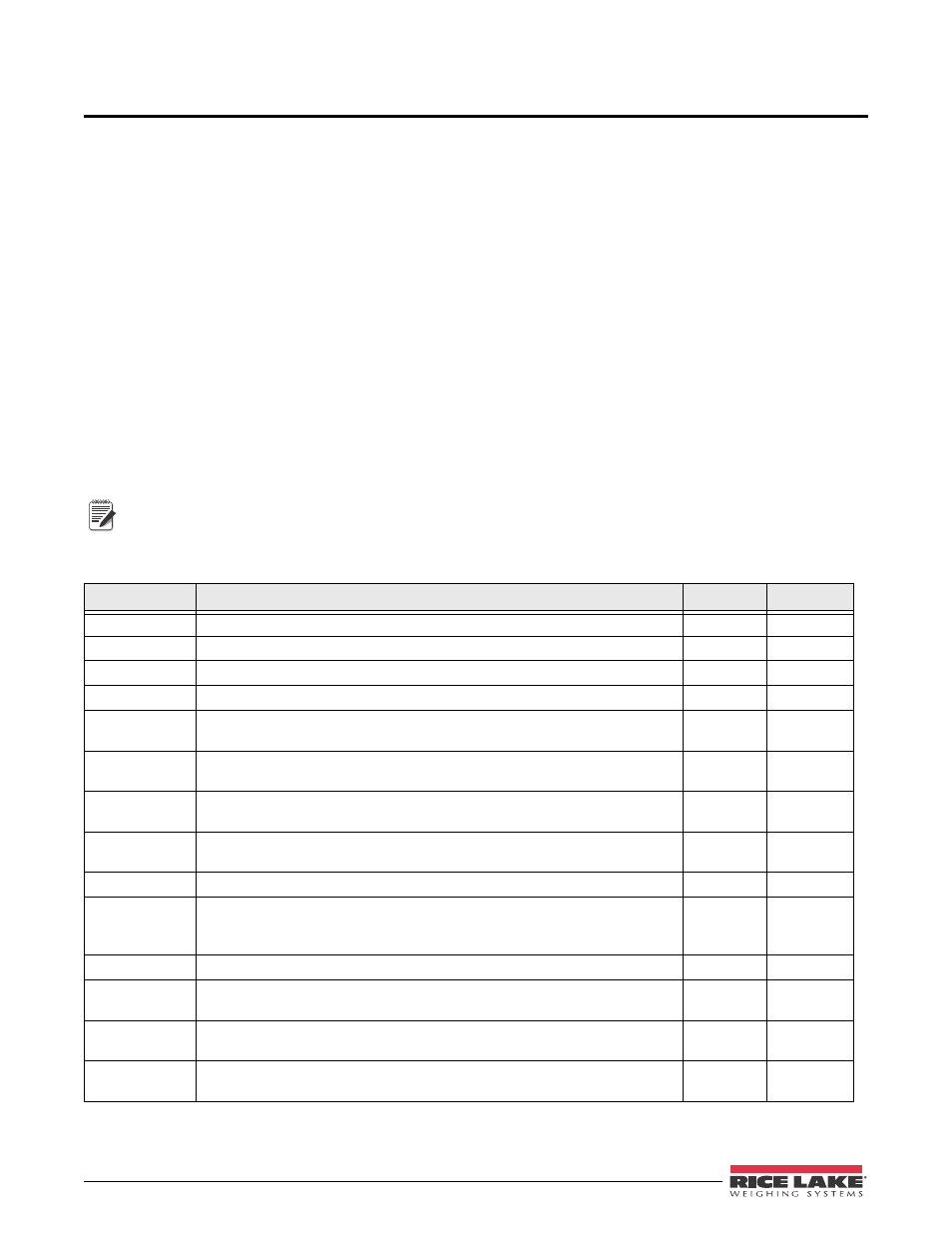

Kind

Description

Batch

Continuous

OFF

Setpoint turned off/ignored.

GROSSSP

Gross setpoint. Trips when the current gross weight matches this value.

NETSP

Net setpoint. Trips when the current net weight matches this value.

+RELSP

Positive relative setpoint. Trips at a specific value above the referenced setpoint.

–RELSP

Negative relative setpoint. Trips at a specific value below the referenced

setpoint.

%RELSP

Percent relative setpoint. Trips at a specific percentage value of the referenced

setpoint.

PAUSE

Pauses the batch sequence indefinitely. Operator must activate the BATSTRT

digital input to continue processing.

DELAY

Delays the batch sequence for a specified time. The length of the delay (in

tenths of a second) is specified on the Value parameter.

WAITSS

Wait for standstill. Holds the batch sequence until the scale is at standstill.

COUNTER

Specifies the number of consecutive batch sequences to perform. A

BATRESET needs to be sent (through either a serial command or digital input)

or a new counter value entered for COUNTER setpoint to function properly.

AUTOJOG

Automatically jogs the previous filling operation.

COZ

Center of zero. The digital output associated with this setpoint is activated

when the scale is at center of zero. No value is required for this setpoint.

INMOTON

In motion. The digital output associated with this setpoint is activated when the

scale is not at standstill. No value is required for this setpoint.

INRANGE

In range. The digital output associated with this setpoint is activated when the

scale is within capacity range. No value is required for this setpoint.

Table 11-1. Setpoint Kinds