Calibration, Output calibration, Co calibration – KMC Controls SAE-1152(NEW Style Board) User Manual

Page 5: Maintenance, Specifications

SAE-1101/1102/1151/1152 Carbon Monoxide (CO) Detectors

5

Installation Guide

Specifications

Range

0–300 ppm

Accuracy and Operation Conditions

±3% of reading @ 32 to 122° F

(0 to 50° C) or ±5% of reading

@ –4 to 122° F (–20 to 50° C),

15 to 95% RH, non-condensing

Response Time

< 35 seconds for 90% step

change

Warm-up Time

200 seconds

Pressure Coefficient 0.020 ±0.008% signal/mbar

Typical Coverage Area 7500 ft

2

(700 m

2

)

Power Supply

15–30 VAC/VDC (non-isolated

half-wave rectified)

Consumption

80 mA max. @ 24 VDC with all

options on, 150 mA average @

24 VAC

Protection Circuitry Reverse voltage protected

and output limited, transient

protection

Wiring Connections Screw terminals (14–22 AWG)

Output Signal

4–20 mA active (sourcing), 0–5

VDC, or 0–10 VDC, jumper

selectable

Output Drive Capability 500 ohm max. for cur-

rent output, 10K ohm min. for

voltage output

Relay Outputs (Optional)

Configuration

Two form “C” contacts (NO

and NC), 5 A @ 250 VAC, 5 A @

30 VDC, power factor = 1

Relay Trip Point Relay 1: Programmable 25 or

40–350 ppm in 10 ppm incre-

ments

Relay 2: Programmable 100–

400 ppm in 10 ppm increments

Relay Hysteresis/Deadband

Programmable 10, 15, 25, 50, or

75 ppm

Weight

1.05 lbs. (0.47 kg)

NOTE: For additional specifications, see the SAE-

1100 Series Data Sheet.

© 2009 KMC Controls, Inc.

717-019-38A

KMC Controls, Inc.

19476 Industrial Drive, New Paris, IN 46553

574.831.5250

www.kmccontrols.com; [email protected]

Maintenance

Careful installation will also ensure long-term reli-

ability and performance. Remove dust as necessary

from holes. Clean with a soft, damp cloth and mild

soap.

Calibration

Output Calibration

If necessary, the current and voltage outputs can be

calibrated as described previously in the Menu Con-

figuration section by using the buttons and a meter

connected to the output. See the Set-Up section.

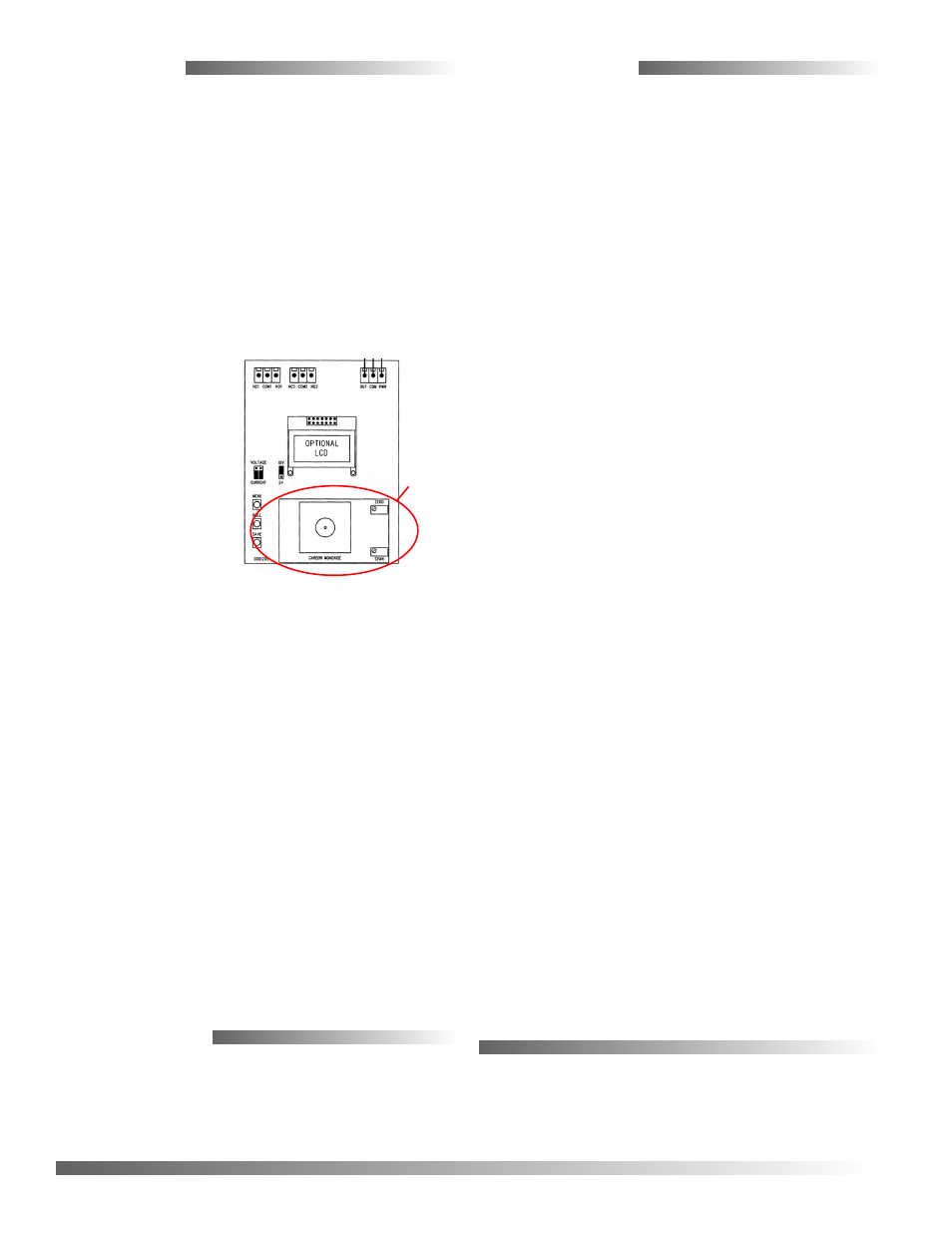

CO Calibration

The detector features a precalibrated, replaceable

sensor module. The sensor module can be un-

plugged and a new calibrated module installed in its

place. To swap sensor modules:

1. Disconnect the

device power.

2. Remove the screws

and cover.

3. Unplug the old

sensor module.

4. Install the new

module, ensuring

the module’s

connector is

properly aligned.

5. Reinstall the cover and screws.

6. Reconnect power.

Making adjustments or applying gas to the transmit-

ter is unnecessary using the sensor swap method.

Calibration of sensor modules should be left to expe-

rienced professionals. Calibration with gas requires

an LCD display, a bottle of gas (250 ppm CO in air), a

tank pressure regulator with flow restrictor, and the

necessary tubing with a cap to cover the sensor. KMC

Controls recommends returning sensor modules to

the factory for calibration. Having a spare, compat-

ible SAE-1100 series detector makes the swap easy,

and the spare module can be conveniently returned

to the factory for recalibration.

NOTE: Newer style boards (without LEDs) are

incompatible with older style sensor

modules and vice versa. See Models

section.

Sensor

Module