Overview, Installation and alignment, 2 reduced resolution (floating blanking) – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 34: 3 fixed blanking, Warning

32

P/N 133487

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

Overview

32

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Installation and Alignment

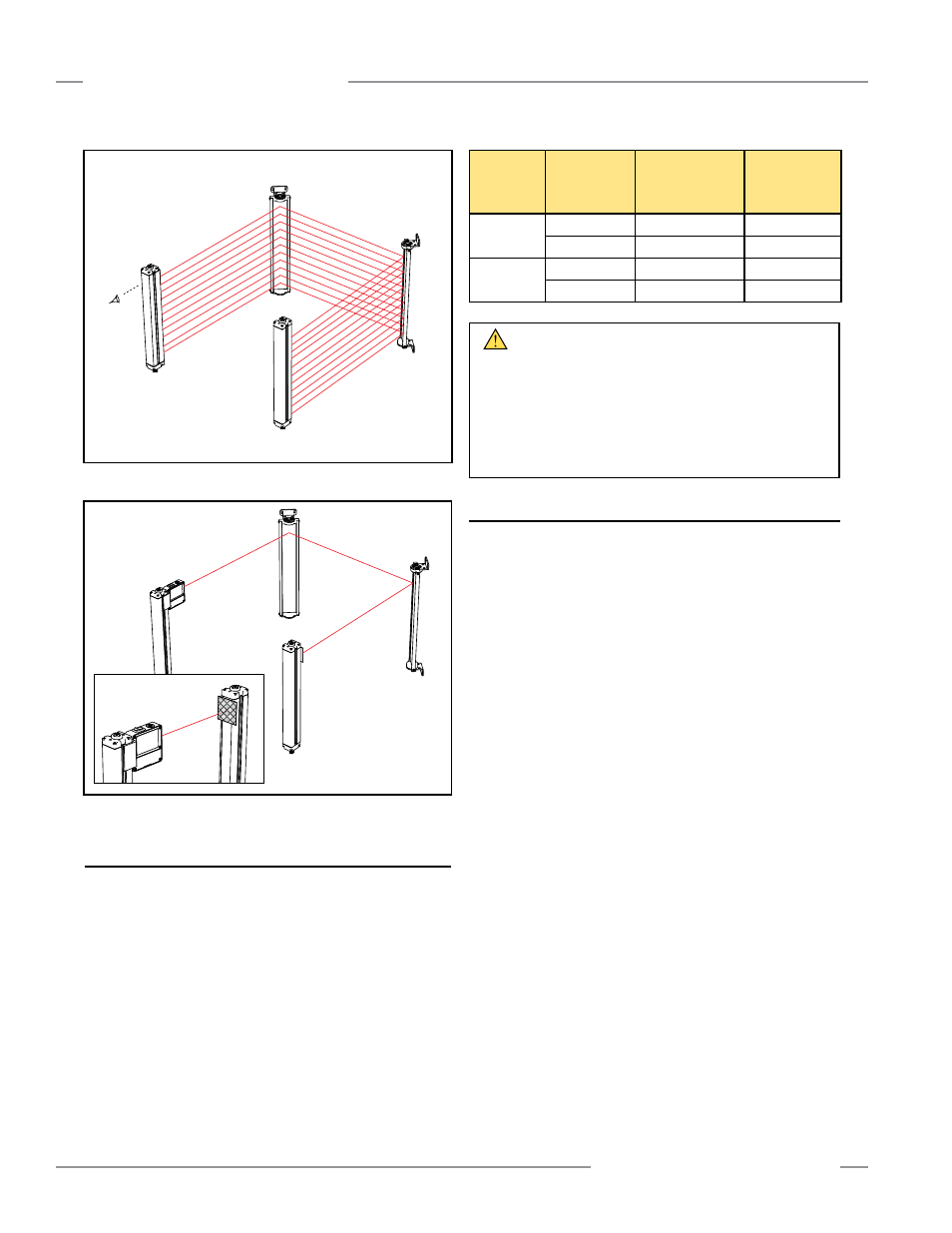

3.4.2 Reduced Resolution (Floating Blanking)

Reduced Resolution allows objects of a certain maximum size to

interrupt the defined area without causing a Trip condition (i.e.,

the OSSDs turn OFF). Use Reduced Resolution only when

necessary. In Reduced Resolution applications, the separation

distance always increases due to the larger depth penetration

factor (Dpf). In either case see Section 3.1.1 to determine

separation distance.

With 2-beam Reduced Resolution enabled, any two

consecutive beams, (except for the sync beam), can be

blocked without causing a stop condition. Thus, multiple “holes”

are created in which 14 mm systems will “see” a 30 mm object

and ignore an 8.5 mm object. Similarily, 30 mm systems will

“see” a 60 mm object and ignore a 17 mm object. See Figure

4-1 for DIP-switch configuration. During operation, the Status

indicator flashes Green when Reduced Resolution is enabled.

Figure 3-12. Corner mirror alignment

Figure 3-13. Optical alignment using the LAT-1

Model

Reduced

Resolution

Setting

Maximum Size

of Undetected

Objects

Resulting

Resolution

14 mm

Resolution

OFF

(Not applicable)

14 mm (0.55")

ON (2-beam)

8.5 mm (0.34")

30 mm (1.18")

30 mm

Resolution

OFF

(Not applicable)

30 mm (1.18")

ON (2-beam)

17 mm (0.67")

60 mm (2.36")

3.4.3 Fixed Blanking

One or multiple areas within an EZ-SCREEN sensor pair may

be blanked out. The minimum number of beams between two

blanked areas is one. Any beam other than the sync beam may

be blanked. All beams of a fixed blanked area must stay blocked

at all times (after the fixed blanking configuration mode has been

exited), in order for the OSSDs to stay ON.

Fixed Blanking Configuration Procedure

1. From normal operation or a power OFF condition, move the

second and third DIP switches (the first RR and T/L) both to

the left (T and RR position). See Figure 3-14.

2. Move the fourth and fifth DIP switches (the second RR and

T/L) both to the right (L and OFF position).

3. The receiver should now either be in a lockout condition or

power is still OFF.

4. If power is OFF: Apply power

Lockout condition: Perform a valid reset sequence (close

the reset switch for 0.25 to 2 seconds, then reopen the

switch).

5. Fixed Blanking configuration indicated by:

• Display alternates between “PFA” and the number of

blocked beams (“0” if all beams are clear).

(PFA = Program Fixed Blanking Active)

• Zone indicators active

• Yellow Reset indicator OFF

• Status indicator ON Red

6. Position object(s) to be blanked.

7. When beams are blocked, the 7-segment display alternates

between “PFA” and the number of blocked beams. The

zone indicators remain active and denote the location of

blocked beams.

WARNING . . .

Use of Reduced Resolution

and Fixed Blanking

Use Reduced Resolution and Fixed Blanking only when

necessary. Any holes created in the defined area either must be

completely filled by the blanked object or the separation distance

must be increased to account for the larger resolution (see Section

3.1.1).

Component #4

(Receiver)

Component #1

(Emitter)

Component #2

(Mirror)

Component #3

(Mirror)