Overview, Installation and alignment, 5 emitter and receiver orientation – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 26: Warning

24

P/N 133487

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

Overview

24

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Installation and Alignment

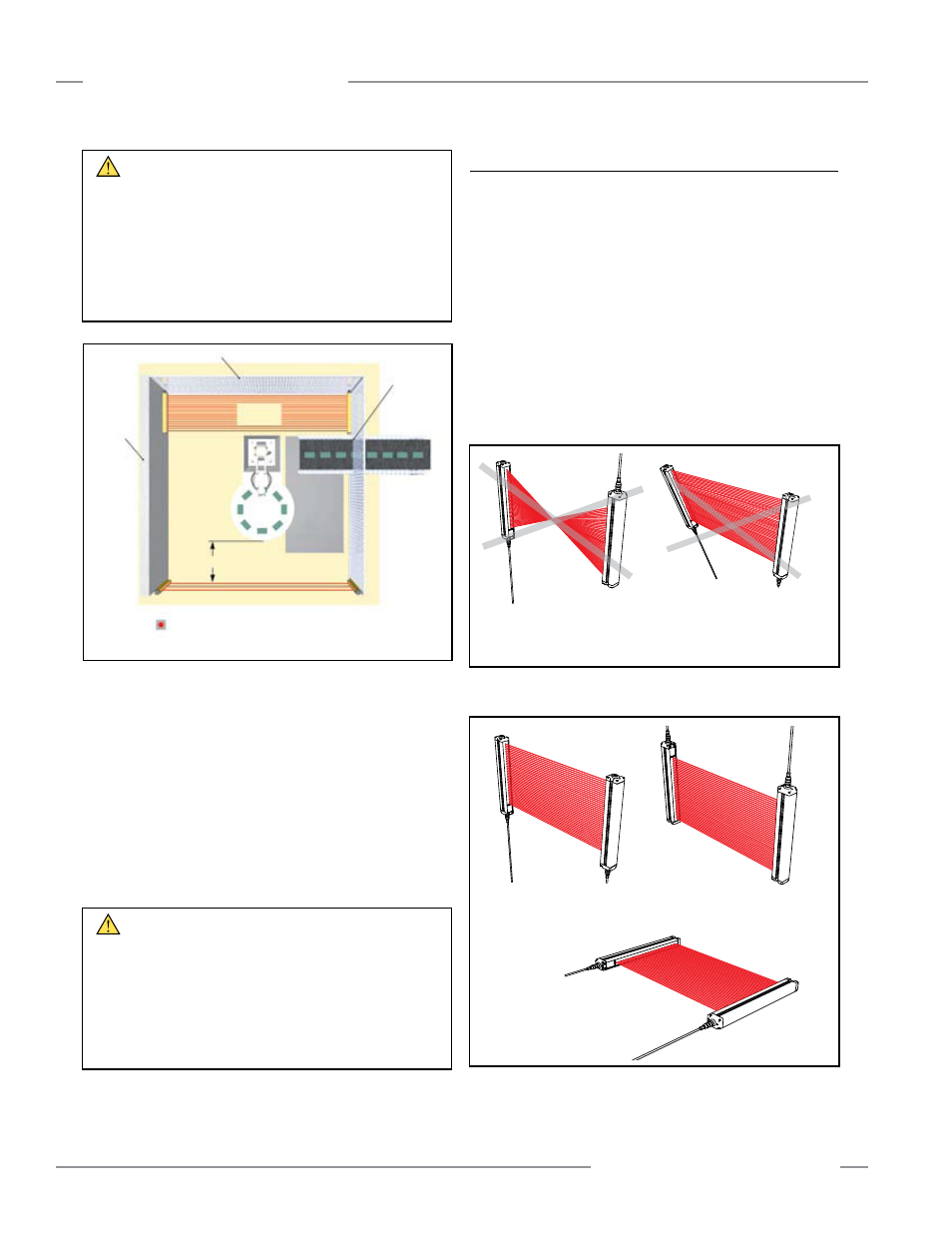

Figure 3-4. Examples of incorrect emitter / receiver orientation

Figure 3-3. An example of supplemental safeguarding

3.1.5 Emitter and Receiver Orientation

The emitter and receiver must be mounted parallel to each other

and aligned in a common plane, with both cable ends pointing

in the same direction. Never mount the emitter with its cable

end oriented opposite the cable end of the receiver. If this

occurs, voids in the light screen may allow objects or

personnel to pass through the defined area undetected (see

Figure 3-4).

The emitter and receiver may be oriented in a vertical or

horizontal plane, or at any angle between horizontal and vertical,

as long as they are parallel and their cable ends point in the

same direction. Verify that the light screen completely covers all

access to the hazard point that is not already protected by hard

guarding or other supplemental guarding.

Figure 3-3 shows an example of supplemental safeguarding

inside a robotic work cell. The EZ-SCREEN, in conjunction

with the hard guarding, is the primary safeguard. Supplemental

safeguarding (such as a horizontal-mounted safety light screen

as an area guard) is required in areas that can not be viewed

from the reset switch (i.e., behind the robot and the conveyor).

Additional supplemental safeguarding may be required to

prevent clearance or trapping hazards (e.g., the safety mat

as an area guard between the robot, the turntable, and the

conveyor).

WARNING . . .

The Hazard Must Be

Accessible Only through the Defined Area

The installation of the EZ-SCREEN must prevent any individual

from reaching around, under, over or through the defined area

and into the hazard without being detected. Mechanical barriers

(e.g., hard guarding) or supplemental safeguarding may be required

to comply with this requirement, and is described by ANSI B11

safety requirements or other appropriate standards.

WARNING . . .

Proper Orientation of

EZ-SCREEN Emitters and Receivers

EZ-SCREEN emitters and receivers must be installed with their

corresponding cabled ends pointing in the same direction (e.g., both

cabled ends “up”). Failure to orient them properly will impair the

performance of the EZ-SCREEN and will result in incomplete

guarding, and could result in serious bodily injury or death.

Figure 3-5. Examples of correct emitter / receiver orientation

a. Both cable ends down

b. Both cable ends up

c. Oriented parallel to floor

with both cable ends pointing in

the same direction

a. Cable ends point in

opposite directions

Problem: Voids in defined area

b. Emitter and receiver not parallel to

each other

Problem: Reduced excess gain

Turn-

table

Area

Guarding

Robot

Hard Guarding

EZ-SCREEN

Reset Switch

Ds

Hard

Guarding

Conveyor

Opening

EZ-SCREEN

Area

Guarding