Overview, Installation and alignment, 7 use of corner mirrors – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 27: 6 adjacent reflective surfaces, Warning

P/N 133487

25

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

Overview

25

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Installation and Alignment

3.1.7 Use of Corner Mirrors

EZ-SCREEN may be used with one or more corner mirrors

(see Section 2.4). The use of glass-surface corner mirrors

reduces the maximum specified emitter/receiver separation by

approximately 8 percent per mirror, as follows:

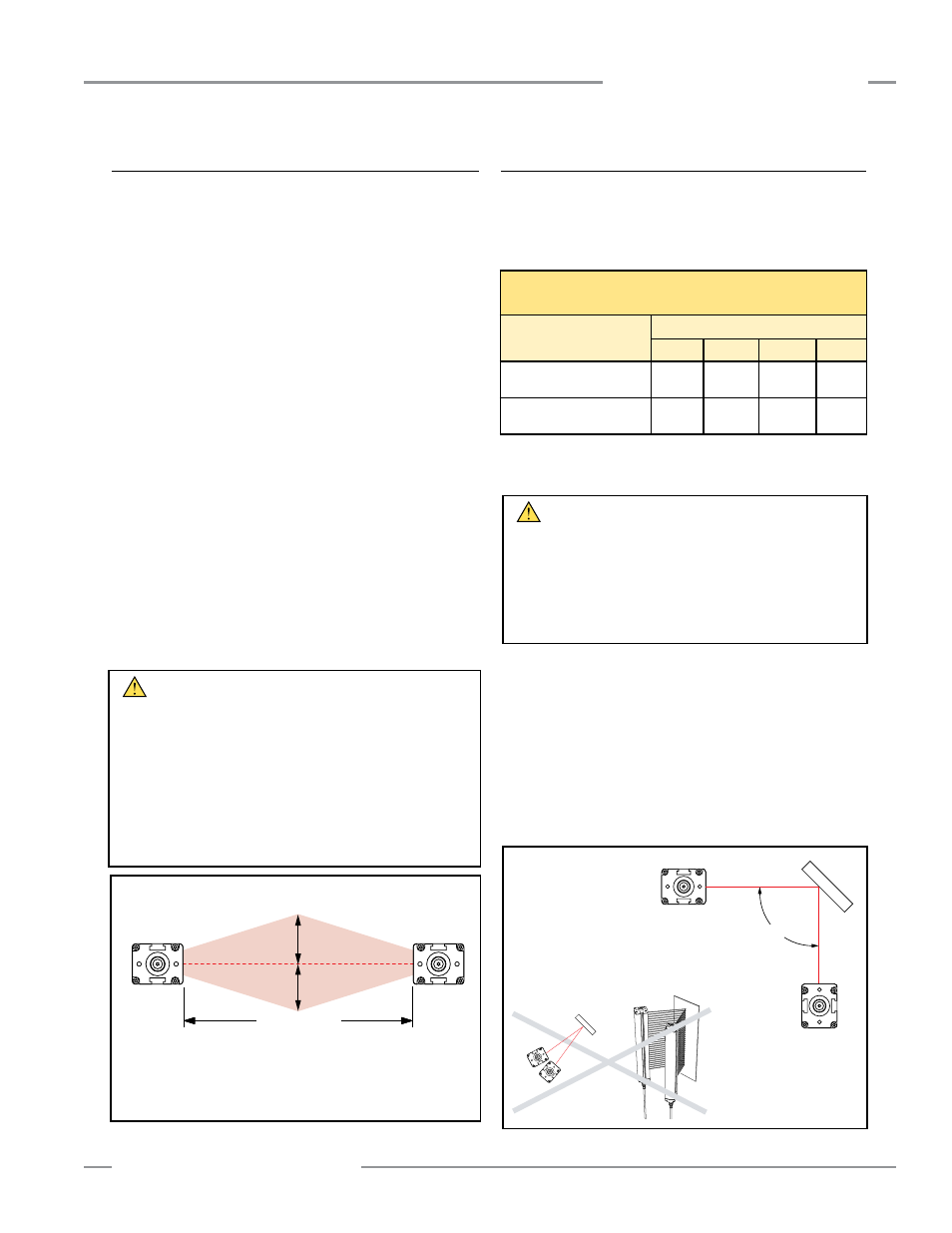

Figure 3-6. Adjacent reflective surfaces

3.1.6 Adjacent Reflective Surfaces

A reflective surface located adjacent to the defined area may

deflect one or more beams around an object in the defined area.

In the worst case, an “optical short circuit” may occur, allowing

an object to pass undetected through the defined area (see

Figure 3-6).

This reflective surface may result from shiny surfaces or glossy

paint on the machine, the workpiece, the work surface, the

floor or the walls. Beams deflected by reflective surfaces

are discovered by performing the trip test portion of the final

alignment procedure and the periodic checkout procedures

(Section 3.4.4).

To eliminate problem reflections:

• If possible, relocate the sensors to move the beams away

from the reflective surface(s), being careful to maintain

adequate separation distance (see Figure 3-6).

• Otherwise, if possible, paint, mask or roughen the shiny

surface to reduce its reflectivity.

•

Where these are not possible (as with a shiny workpiece),

mount the sensors in such a way that the receiver’s field of

view and/or the emitter’s spread of light are restricted.

•

Repeat the trip test to verify that these changes have

eliminated the problem reflection(s). If the workpiece is

especially reflective and comes close to the defined area,

perform the trip test with the workpiece in place.

Mirrors are not allowed for applications that would allow

personnel undetected access into the safeguarded area.

If mirrors are used, the difference between the angle of

incidence from the emitter to the mirror and from the mirror to

the receiver must be between 45° and 120° (see Figure 3-7).

If placed at a sharper angle, as shown in the example, an

object in the light screen may deflect beam(s) to the receiver,

preventing the object from being detected (i.e., “false proxing”).

Angles greater than 120° result in difficult alignment and

possible optical short circuits.

See the specific mirror data sheet or the Banner Safety Catalog

for further information.

SSM and MSM Series Glass-Surface Mirrors –

Maximum Emitter and Receiver Separation

Sensor Models

Number of Corner Mirrors

1

2

3

4

14 mm Resolution Models

6 m (20') Range

5.5 m

(18')

5.1 m

(17')

4.7 m

(15.5')

4.3 m

(14')

30 mm Resolution Models

18 m (60') Range

16.6 m

(54.5')

15.3 m

(50')

14.1 m

(46.5')

13 m

(43')

Figure 3-7. Never use EZ-SCREEN sensors in a retroreflective mode.

WARNING . . .

Avoid Retroreflective

Installation

Do not install emitters and receivers in “retroreflective” mode,

with less than a 45° angle of incidence, as shown in Figure 3-7.

Sensing could be unreliable in this configuration; serious

bodily injury or death could result.

WARNING . . .

Avoid Installation Near

Reflective Surfaces

Avoid locating the defined area near a reflective surface; it could

reflect sensing beam(s) around an object or person within the

defined area, and prevent its detection by the EZ-SCREEN System.

Perform the trip test, as described in Section 3.4.4, to detect such

reflection(s) and the resultant optical short circuit.

Failure to prevent reflection problems will result in incomplete

guarding and could result in serious bodily injury or death.

Recommended sensor

configuration angle:

45° < A < 120°

Mirror

A

Receiver

Emitter

Mirror

Receiver

Emitter

Emitter

Receiver

Do not position reflective surfaces

within the shaded area

Operating Range

(R)

At installed operating range (R):

d=0.0437 × R (m or ft)

Operating range 0.1 to 3 m (4" to 10'): d = 0.13 m (5")

Operating range >3 m ( > 10’): d = 0.0437 × R (m or ft)

d

d