Overview, Installation and alignment, 2 mechanical mounting procedure – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 30: 1 sensor mounting

28

P/N 133487

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

Overview

28

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com

•

Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Installation and Alignment

3.2 Mechanical Mounting Procedure

Once the mechanical layout considerations of Section 3.1 are

addressed, mount the sensors and route the cables.

3.2.1 Sensor Mounting

Emitter/receiver pairs with 14 mm (0.55") resolution may be

spaced from 0.1 m to 6 m (4" to 20') apart. Emitter/receiver

pairs with 30 mm (1.18") resolution may be spaced from

0.1 m to 18 m (4" to 60') apart. The maximum distance between

an emitter and its receiver is reduced if corner mirrors are used

(see Section 3.1.7). The supplied brackets (when mounted to

the sensor end caps) allow ±30° rotation.

From a common point of reference (ensuring the minimum

separation distance calculated in Section 3.1.1), make

measurements to locate the emitter and receiver in the same

plane with their midpoints directly opposite each other.

Important: The connector ends of both sensors must point

in the same direction (see Figure 3-5 and warning, Section

3.1.3). Mount the emitter and receiver mounting brackets (see

below) using the supplied M6 bolts and Keps nuts, or user-

supplied hardware; see Figure 3-9.

Mount the emitter and receiver in their brackets; position their

windows directly facing each other. Measure from a reference

plane (e.g., a level building floor) to the same point(s) on the

emitter and receiver to verify their mechanical alignment. Use

a carpenter’s level, a plumb bob, or the optional LAT-1 Laser

Alignment Tool (see Section 2.5) or check the diagonal distances

between the sensors, to achieve mechanical alignment. Final

alignment procedures are explained in Section 3.4.

Center mounting brackets must be used with longer sensors,

whenever the sensors are subject to shock or vibration. In such

situations, the sensors are designed to be mounted with up

to 900 mm unsupported distance (between brackets). Sensors

1050 mm and longer are supplied with a center bracket to be

used as needed with the standard end-cap brackets (see Figure

3-9).

1. Attach the center bracket to the mounting surface when

mounting the end-cap brackets.

2. Attach the clamp to both slots of the housing, using the

included M5 screws and T-nuts.

3. After the sensor is mounted to the end-cap brackets, attach

the clamp to the center bracket using the supplied M5 screw.

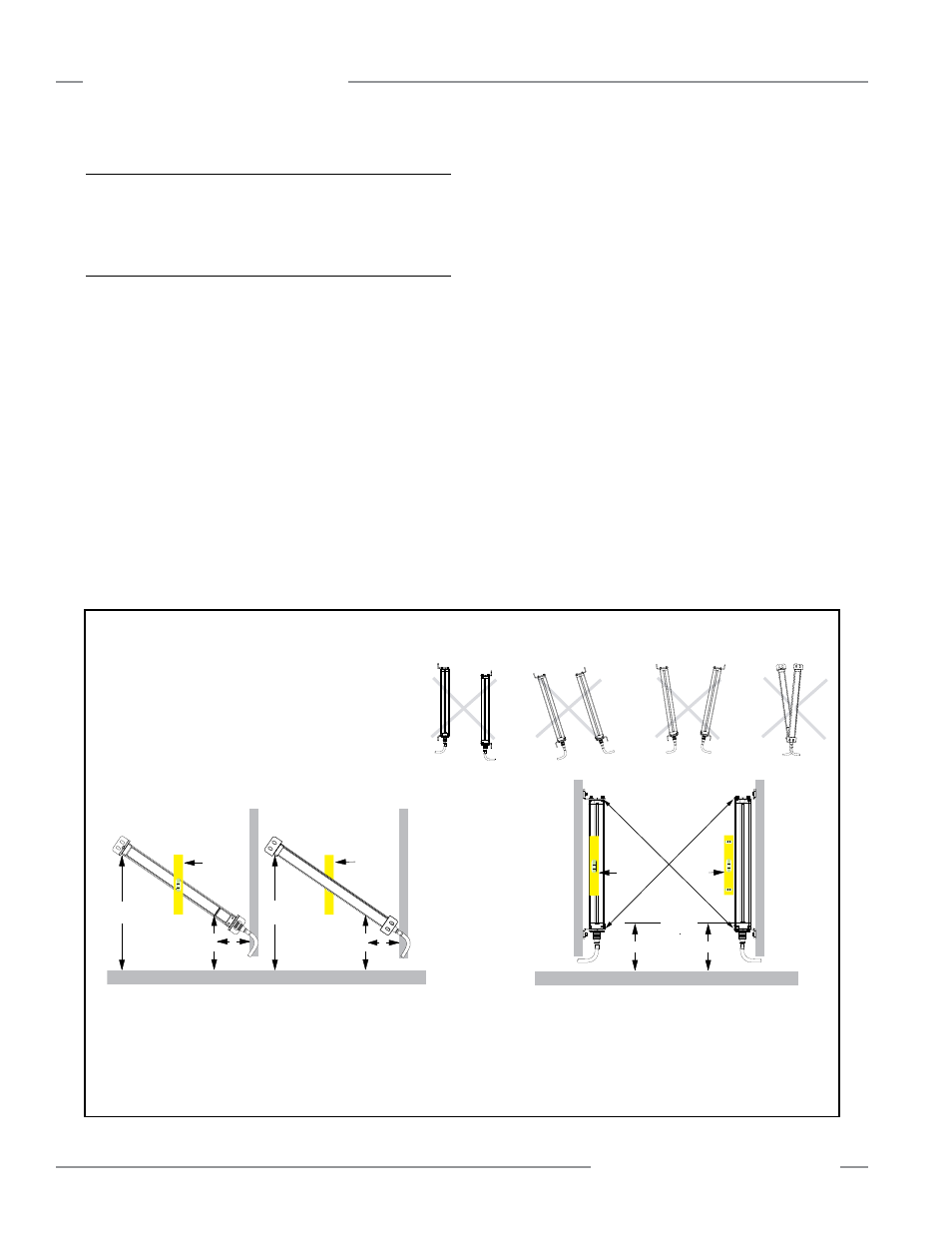

Figure 3-10. Sensor mounting, mechanical alignment

A

B

Verify that:

•

The emitter and receiver are directly opposite each other.

• Nothing is interrupting the defined area.

•

The defined area (marked on the sensors) is the same distance

from a common reference plane for each sensor.

•

The emitter and receiver are in the same plane and are

level/plumb and square to each other (vertical, horizontal,

or inclined at the same angle, and not tilted front-to-back or

side-to-side).

Angled or Horizontal Installations – verify that:

• Distance X at the emitter and receiver are equal.

• Distance Y at the emitter and receiver are equal.

• Distance Z at the emitter and receiver are equal from parallel

surfaces.

• Vertical face (i.e., the window) is level/plumb.

•

Defined area is square. Check diagonal measurements if possible; see

Vertical Installations, at right.

Vertical Installations – verify that:

• Distance X at the emitter and receiver are equal.

• Both sensors are level/plumb (check both the

side and face).

•

Defined area is square. Check diagonal measurements if

possible (Diagonal A = Diagonal B).

Receiver

Emitter

Level

Y

X

Z

Level Surface

Receiver

Emitter

Level

Y

X

Z

B

A

Level Surface

Level

X

Level

X