Armored cable – Rockwell Automation 1336T Wiring and Grounding Guide, (PWM) AC Drives User Manual

Page 17

Rockwell Automation Publication DRIVES-IN001M-EN-P - March 2014

17

Wire/Cable Types Chapter 1

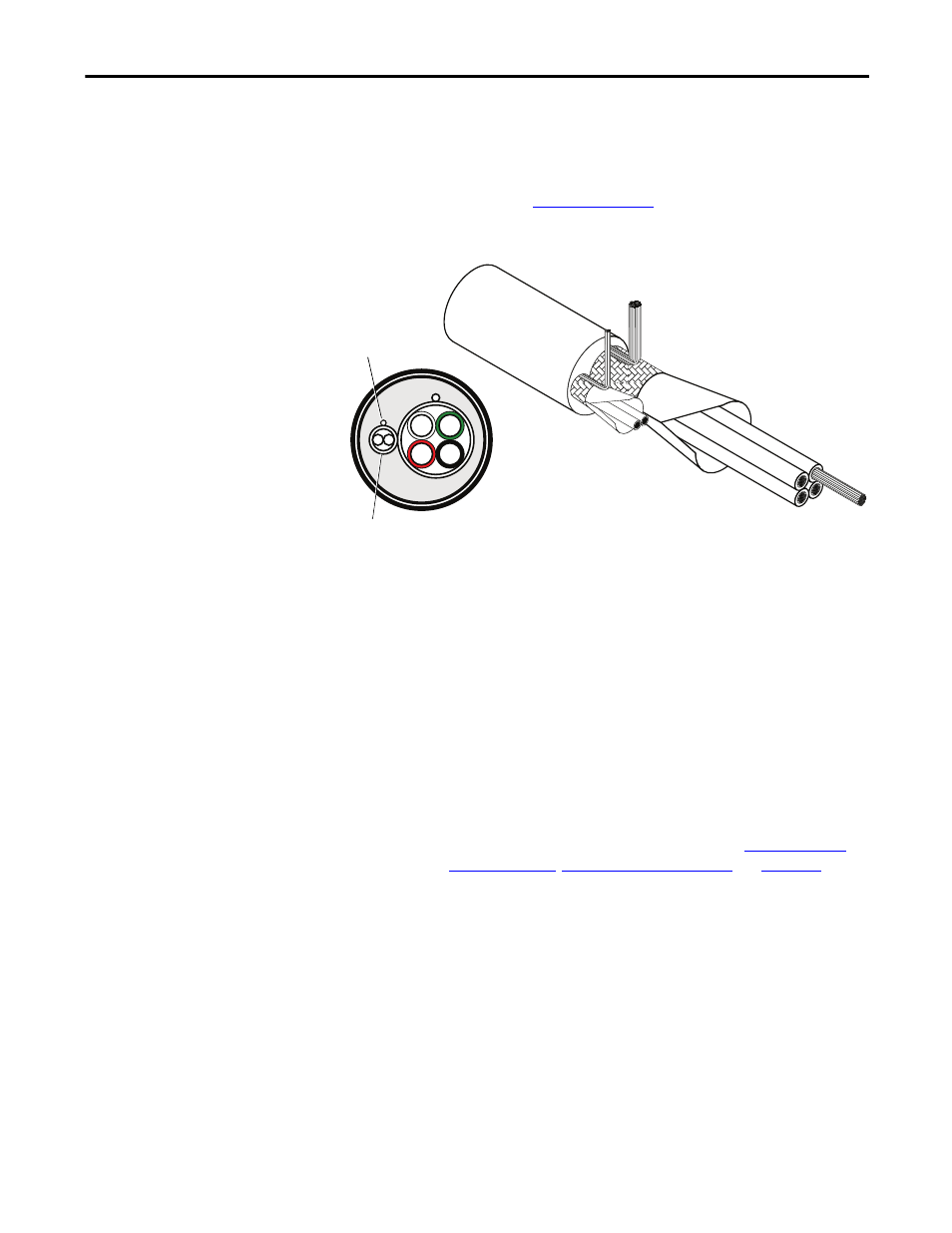

Type 2 Installation

An acceptable shielded cable for Type 2 installations is essentially the same cable

as Type 1, plus one shielded pair of brake conductors. For more information on

Type 2 installations, refer to

.

Figure 8 - Type 2 Installation — Shielded Cable with Brake Conductors

Type 3 Installation

These cables have 3 XLPE insulated copper conductors, 25% minimal overlap

with helical copper tape, and three bare copper grounds in PVC jacket.

Armored Cable

Cable with continuous aluminum armor is often recommended in drive system

applications or specific industries. Armored cable offers most of the advantages of

standard shielded cable and also combines considerable mechanical strength and

resistance to moisture. It can be installed in concealed and exposed manners and

removes the requirement for conduit (electrical metallic tubing [EMT]) in the

installation. It can also be directly buried or embedded in concrete.

B

R

G

W

Drain Wire for Brake

Conductor Shield

Shield for Brake

Conductors

TIP

Other types of shielded cable are available, but the selection of these types can

limit the allowable cable length. Particularly, some of the newer cables twist four

conductors of THHN wire and wrap them tightly with a foil shield. This

construction can greatly increase the cable charging current required and reduce

the overall drive performance. Unless specified in the individual distance tables

as tested with the drive, these cables are not recommended and their

performance against the lead length limits supplied is not known. For more

information about motor cable lead restrictions, refer to,

,

Effects On Wire Types on page 73

, and

.

- 1336E Wiring and Grounding Guide, (PWM) AC Drives 1336F Wiring and Grounding Guide, (PWM) AC Drives 1336S Wiring and Grounding Guide, (PWM) AC Drives 1336VT Wiring and Grounding Guide, (PWM) AC Drives 1336 Wiring and Grounding Guide, (PWM) AC Drives 1305 Wiring and Grounding Guide, (PWM) AC Drives 25B Wiring and Grounding Guide, (PWM) AC Drives 20N Wiring and Grounding Guide, (PWM) AC Drives 20M Wiring and Grounding Guide, (PWM) AC Drives 22C Wiring and Grounding Guide, (PWM) AC Drives 22B Wiring and Grounding Guide, (PWM) AC Drives 22A Wiring and Grounding Guide, (PWM) AC Drives 20D Wiring and Grounding Guide, (PWM) AC Drives 20C Wiring and Grounding Guide, (PWM) AC Drives 20B Wiring and Grounding Guide, (PWM) AC Drives 20A Wiring and Grounding Guide, (PWM) AC Drives 1336R Wiring and Grounding Guide, (PWM) AC Drives