Insulation thickness and concentricity, Geometry, Insulation thickness and concentricity geometry – Rockwell Automation 1336T Wiring and Grounding Guide, (PWM) AC Drives User Manual

Page 14

14

Rockwell Automation Publication DRIVES-IN001M-EN-P - March 2014

Chapter 1 Wire/Cable Types

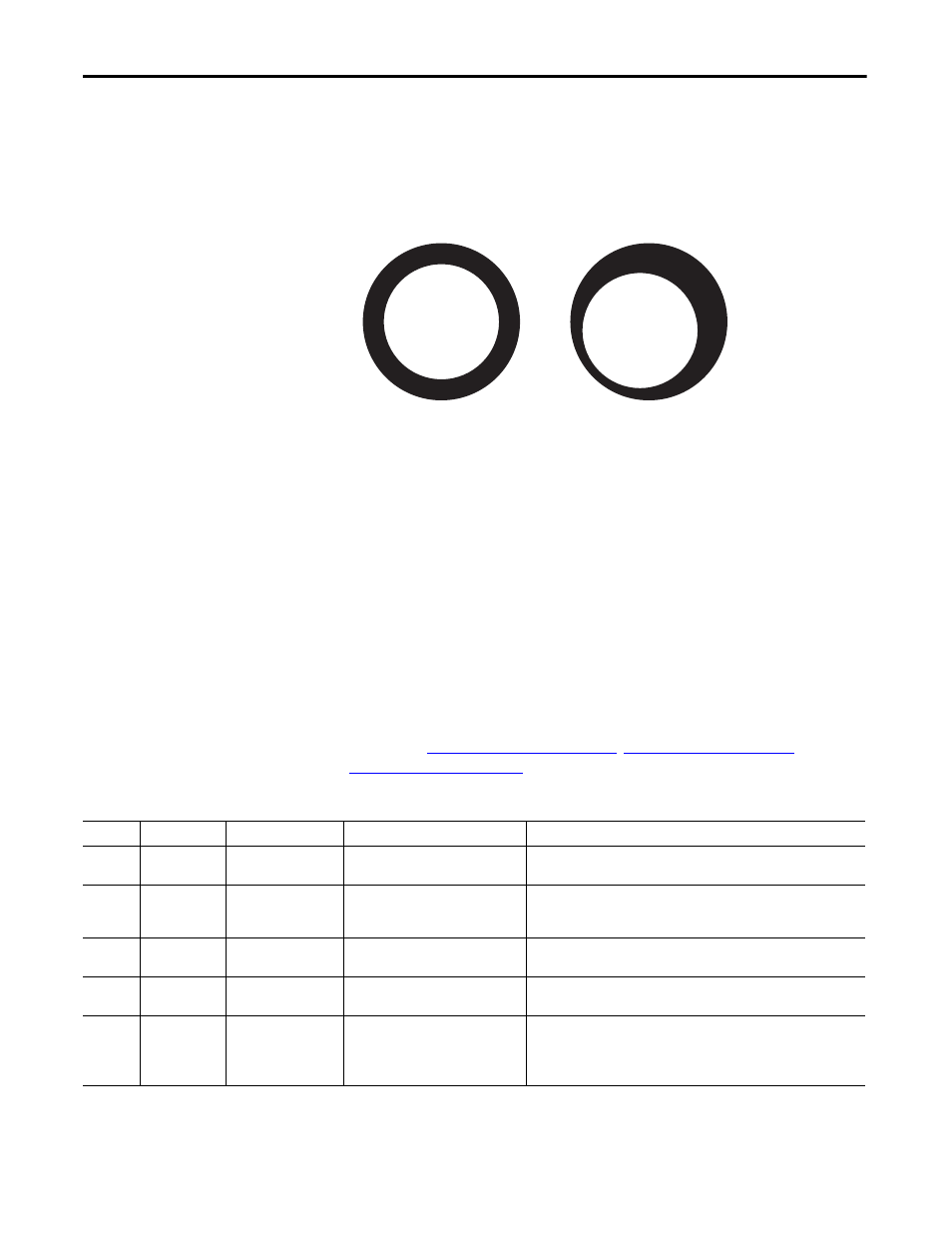

Insulation Thickness and Concentricity

Wire must have an insulation thickness of

≥ 15 mil (0.4 mm/0.015 in.). The wire

insulation must not have significant variations of concentricity around the wire.

Figure 4 - Insulation Concentricity

Geometry

The physical relationship between individual conductors is important in drive

installations.

Individual conductors in conduit or cable trays have no fixed relationship and are

subject to cross coupling of noise, induced voltages, excess insulation stress, and

other possible interference.

Fixed geometry cable (cable that keeps the spacing and orientation of the

individual conductors constant) offers significant advantages over individual

loose conductors, including reduced cross-coupling noise and insulation stress.

Three types of fixed geometry, multi-conductor cables are discussed in this

section. See

, and

.

Table 1 - Recommended Cable Design

Unacceptable

Acceptable

Type

Max Wire Size

Where Used

Rating/Type

Description

Type 1

2 AWG

Standard installations

100 Hp or less

600V, 90 °C (194 °F)

XHHW2/RHW-2

Four tinned copper conductors with cross-linked polyethylene (XLPE)

insulation

Type 2

2 AWG

Standard installations

100 Hp or less

with brake conductors

600V, 90 °C (194 °F)

RHH/RHW-2

Four tinned copper conductors with XLPE insulation plus one shielded pair of

brake conductors.

Type 3

500 MCM AWG

Standard installations

150 Hp or more

Tray-rated 600V, 90 °C (194 °F)

RHH/RHW-2

Three tinned copper conductors with XLPE insulation and three bare copper

grounds and polyvinyl chloride (PVC) jacket.

Type 4

500 MCM AWG

Water, caustic chemical,

crush resistance

Tray-rated 600V, 90 °C (194 °F)

RHH/RHW-2

Three bare copper conductors with XLPE insulation and three copper grounds

on 10 AWG and smaller. Acceptable in Class I and II, Division I and II locations.

Type 5

500 MCM AWG

690V applications

Tray-rated 2000V, 90 °C (194 °F)

Three tinned copper conductors with XLPE insulation. Three bare copper

grounds and PVC jacket.

IMPORTANT: If terminator network or output filter is used, connector

insulation must be XLPE, not PVC.

- 1336E Wiring and Grounding Guide, (PWM) AC Drives 1336F Wiring and Grounding Guide, (PWM) AC Drives 1336S Wiring and Grounding Guide, (PWM) AC Drives 1336VT Wiring and Grounding Guide, (PWM) AC Drives 1336 Wiring and Grounding Guide, (PWM) AC Drives 1305 Wiring and Grounding Guide, (PWM) AC Drives 25B Wiring and Grounding Guide, (PWM) AC Drives 20N Wiring and Grounding Guide, (PWM) AC Drives 20M Wiring and Grounding Guide, (PWM) AC Drives 22C Wiring and Grounding Guide, (PWM) AC Drives 22B Wiring and Grounding Guide, (PWM) AC Drives 22A Wiring and Grounding Guide, (PWM) AC Drives 20D Wiring and Grounding Guide, (PWM) AC Drives 20C Wiring and Grounding Guide, (PWM) AC Drives 20B Wiring and Grounding Guide, (PWM) AC Drives 20A Wiring and Grounding Guide, (PWM) AC Drives 1336R Wiring and Grounding Guide, (PWM) AC Drives