Power supply tests, Sts (refer to, Chapter 3 – Rockwell Automation MV SMC Flex Motor Controller (for Series K or later) User Manual

Page 74

64

Rockwell Automation Publication 1560E-UM051F-EN-P - June 2013

Chapter 3

Commissioning Procedure

Power Supply Tests

1.

Isolate incoming power.

2.

Open the door(s) providing access to the SCR/heatsink assemblies. You

will be touching components which are connected to the high voltage

power circuit, so be sure to isolate power as stated above.

3.

Apply rated control voltage to the control circuits from a separate control

source, or by plugging into the test source connector, and selecting the

TEST position of the control switch.

4.

Check voltage on each gate driver board by connecting a DC voltmeter at

TP4(+) and TP3(-). (See

.) The voltage should be 18 - 22V DC.

5.

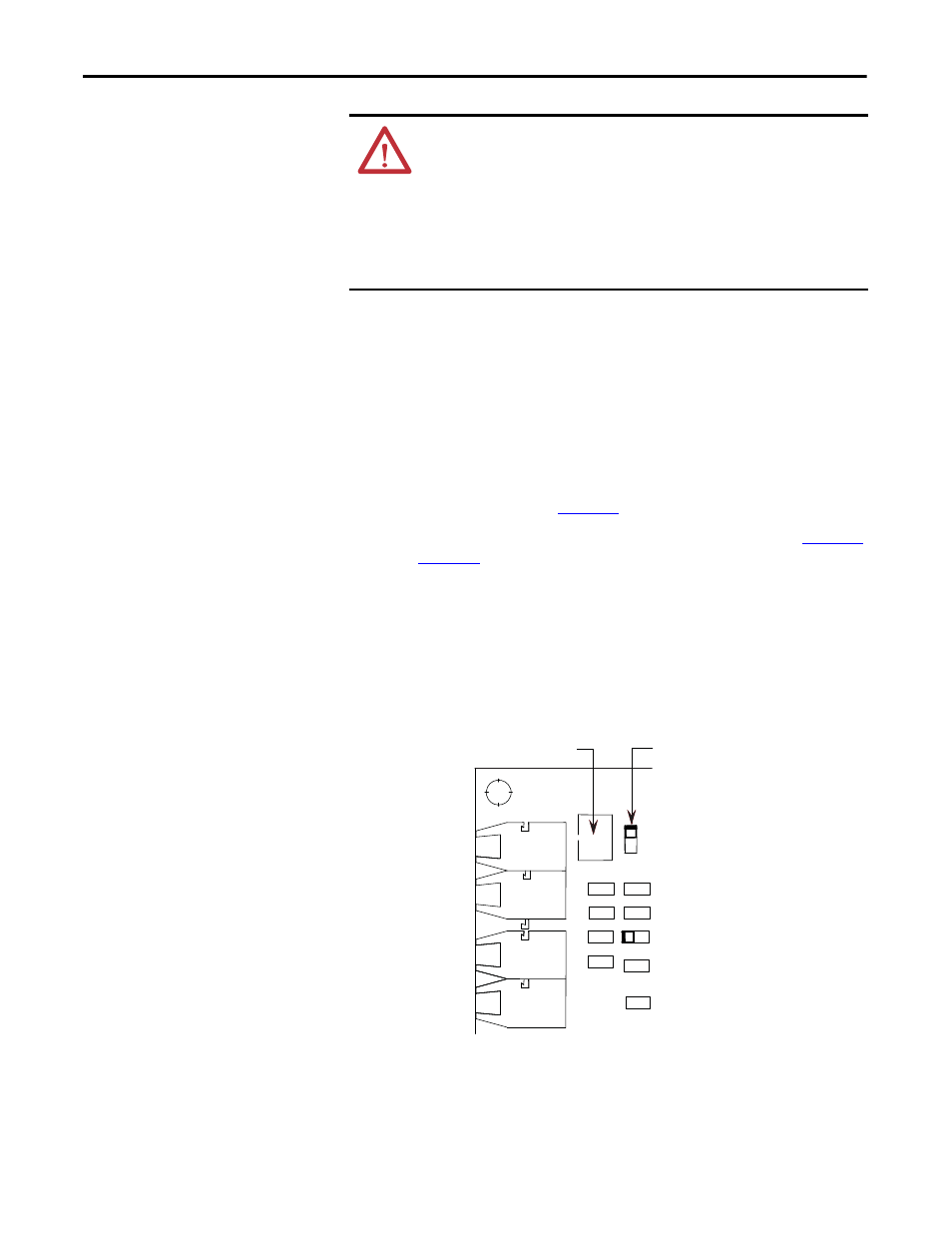

Locate the SMC Flex Interface board in the control section (See

). This circuit board has the control module mounted on it.

Locate the switch labeled SW2 at the upper left corner of the board. Close

the switch by sliding the toggle up. This starts a pulse generator to supply

simulated gate-pulse signals via fiber optic cables to the gate driver boards.

A red LED beside the switch, and the three yellow LEDs on the left side of

the Interface board should be lit. (Note: They may appear dim, depending

on ambient light conditions).

Figure 38 - Interface PCB

ATTENTION: Servicing energized industrial control equipment can be

hazardous. Severe injury or death can result from electrical shock, burn, or

unintended actuation of controlled equipment. Before proceeding, ensure that

all sources of power are isolated and locked out. Verify that all circuits are

voltage free using a hot stick or appropriate voltage measuring device. Any

covers or barriers removed during this procedure must be replaced and securely

fastened before energizing equipment. Where appropriate, the case of test

equipment should be connected to ground.

SW2 – Close (slide up) to initiate test pulses

Red LED – ON when test pulses active

D1

SW2