Table 19, Table 20, Table 21 – Rockwell Automation MV SMC Flex Motor Controller (for Series K or later) User Manual

Page 127: Table 22

Rockwell Automation Publication 1560E-UM051F-EN-P - June 2013

117

Troubleshooting

Chapter 9

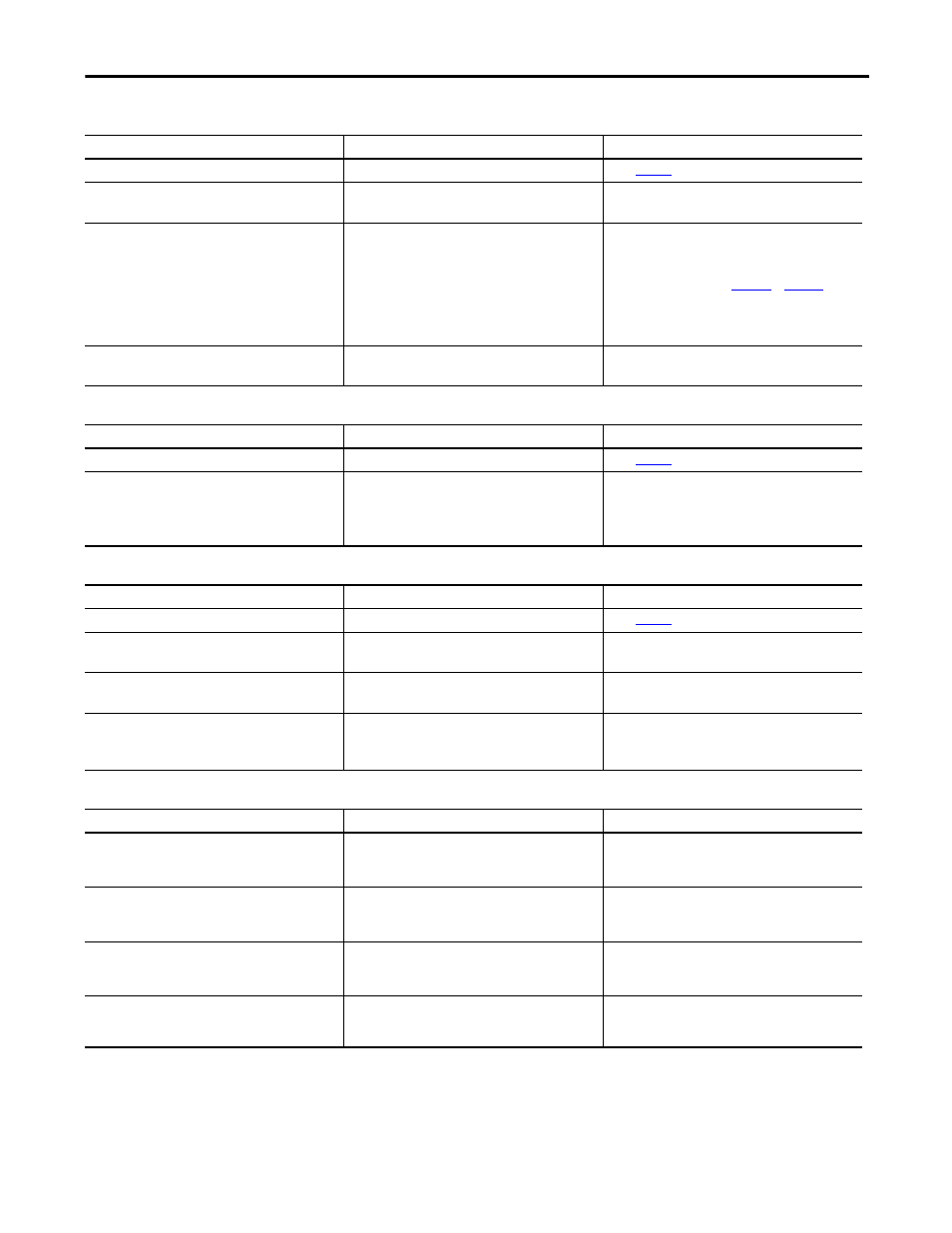

Table 19 - Motor Will Not Start – No Output Voltage to the Motor

Table 20 - Motor Rotates (but does not accelerate to full speed)

Table 21 - Motor Stops While Running

Table 22 - Irregular Starts

Display

Possible Causes

Possible Solutions

Fault displayed

• See fault description

• See

addressing fault conditions

Display is blank

• Control voltage is absent

• Failed control module

• Check control wiring and correct if necessary

• Replace control module

Stopped 0.0 Amps

• Pilot devices

• SMC Enable input is open at terminal 13

• Terminal 16 is open

• Start-Stop control has not been enabled for the human

interface module

• Control voltage

• Failed control module

• Check wiring

• Check wiring

• Check wiring

• Follow the instructions on

to

enable control capability

• Check control voltage

• Replace control module

Starting

• Two or three power phases are missing

• Check power system

• Check voltage sensing module and connections

Display

Possible Causes

Possible Solutions

Fault displayed

• See fault description

• See

addressing fault conditions

Starting

• Mechanical problems

• Inadequate Current Limit setting

• Failed control module

• Check for binding or external loading and correct

• Check motor

• Adjust the Current Limit Level to a higher setting

• Replace control module

Display

Possible Causes

Possible Solutions

Fault displayed

• See fault description

• See

addressing fault conditions

Display is blank

• Control voltage is absent

• Failed control module

• Check control wiring and correct if necessary

• Replace control module

Stopped 0.0 Amps

• Pilot devices

• Failed control module

• Check control wiring and correct if necessary

• Replace control module

Starting

• Two or three power phases are missing

• Failed control module

• Check power system

• Check voltage sensing module and connections

• Replace control module

Symptom

Possible Causes

Possible Solutions

Bypass contactor closes before motor is up to speed

• Ramp time too short

• Motor characteristics cause Up-to-Speed sensing too

early

• Increase ramp time (parameter 18)

• Adjust parameter 114 higher (no more than 5% at a

time)

Motor is up to speed but bypass contactor is delayed in

closing or does not close at all

• Ramp time too long

• Motor characteristics cause Up-to-Speed sensing too

late or not at all

• Decrease ramp time

• Adjust parameter 114 lower (no more than 5% at a

time)

Rough start, erratic current, growling from the motor

(may see Line Faults)

• Poor grounding of the power system or controller

• Poor power quality, electrical noise, harmonics, VFD line

notching

• Resolve ground issues

• Adjust parameter 117 higher. Typical settings are 35 or

40. Not recommended to exceed 75 or go below 25.

During a Pump Stop, the motor takes more than 5 seconds

to begin to decelerate or takes longer than the

programmed stop time

• Motor or pump characteristics do not match the default

setting

• Adjust parameter 34 to between 20 and 30 (not

recommended to go above 40).

TIP

Although the default settings accommodate the vast majority of applications,

these tuning parameters may require more than one adjustment to achieve

optimal results. Some parameters are affected by motor loading and power

system conditions, so one setting may not be optimal for all conditions.