3 electronic gear unit with "flying saw – NORD Drivesystems BU0550 User Manual

Page 60

PLC logic for NORD SK 54xE frequency inverters

60

BU 0550 GB-0813

3.5.3

Electronic gear unit with "Flying Saw"

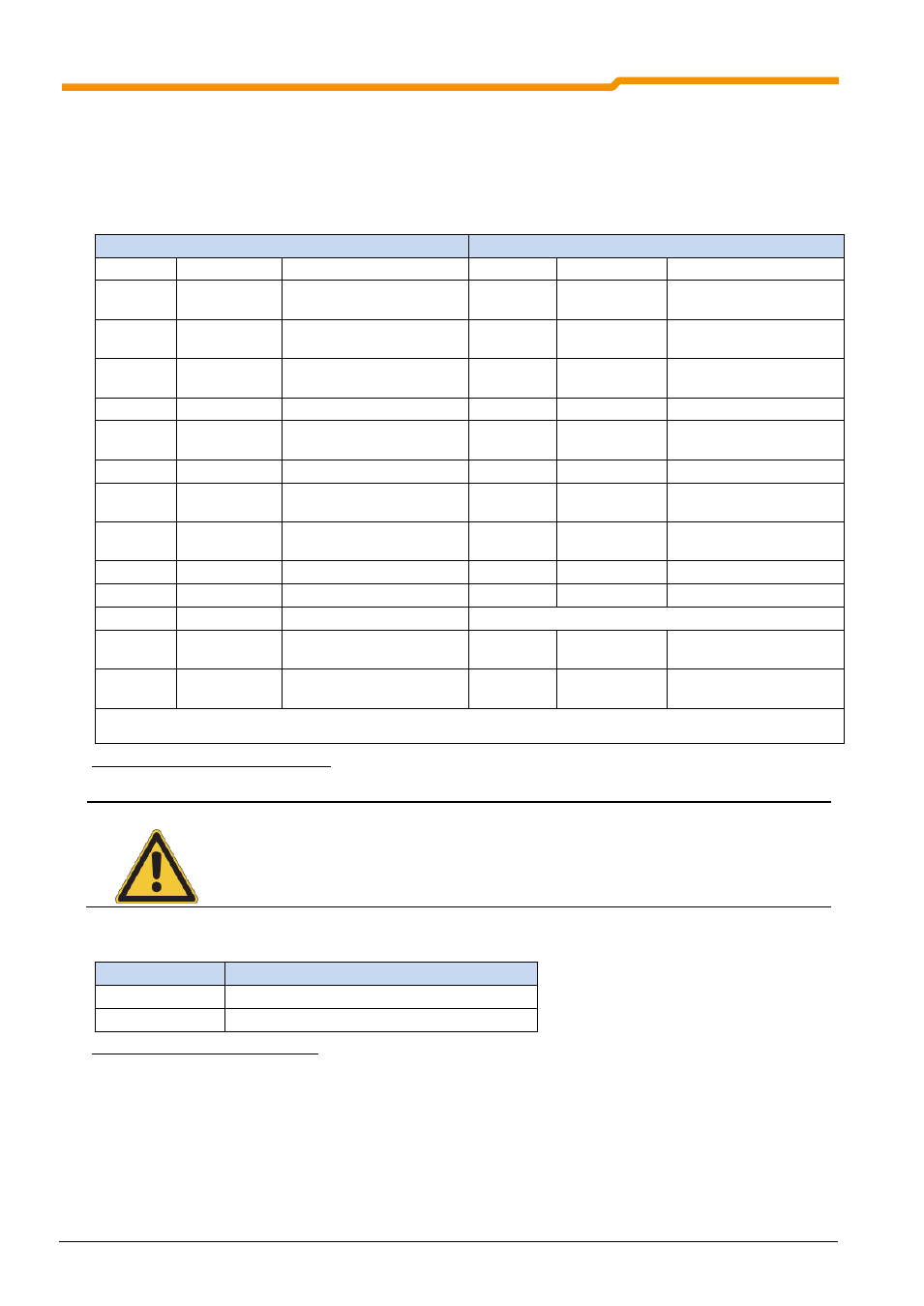

There are two function blocks which allow control of the functions electronic gear unit ("angular

synchronisation") and the sub-function Flying Saw. In addition, various parameters must be set for the

correct execution of the two function blocks in the master and slave frequency inverters. An example of this

is shown in the following table.

Master FI

Slave FI

Parameter

Setting

Meaning

Parameter

Setting

Meaning

P502[-01]

20

Setpoint frequency

according to freq. ramp

P509

10 *

CANopen Broadcast *

P502[-02]

15

Actual position in

inc. High word

P510 [-01]

10

CANopen Broadcast

P502[-03]

10

Actual position in

inc. Low word

P510 [-02]

10

CANopen Broadcast

P503

3

CANopen

P505

0

0.0Hz

P505

0

0.0Hz

P515 [-02]

P515[-03]

Master

Broadcast - Slave

address

P514

5

250kBaud (min. 100kBaud)

P546 [-01]

4

Frequency addition

P515 [-03]

P515[-02]

Slave

Broadcast

– Master

address

P546 [-02]

24

Setpoint position in

inc. High word

P546 [-03]

23

Setpoint position in

inc. Low word

P600

1,2

Position control ON

Only for FB_Gearing

P553[-01]

21

Position setpoint pos.

Low word

P553[-02]

22

Position setpoint pos.

High word

* (P509) must not necessarily be set to {10} "CANopen Broadcast". However in this case(P502 [-01]) on the master must be set to

{21} "Actual frequency without slip".

Table 85 Parameterisation for gear function

NOTE

The actual position of the master MUST be communicated in "Increments" (Inc) format.

3.5.3.1

Overview

Function module

Explanation

FB_Gearing

FB for simple gear unit function

FB_FlyingSaw

FB for gear unit function with Flying Saw

Table 86 Overview of electronic gear unit