7 program example – NORD Drivesystems BU0550 User Manual

Page 19

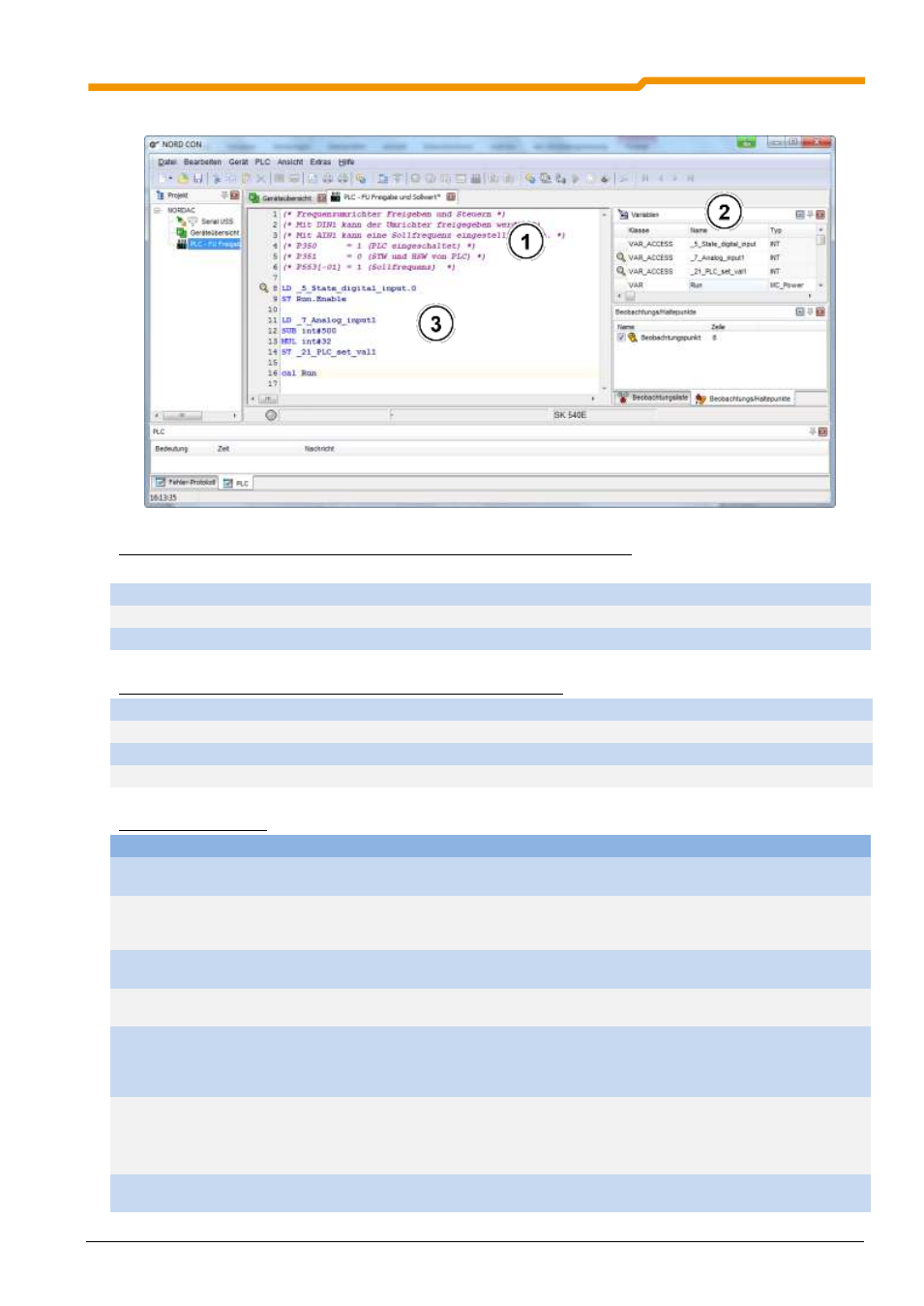

3 AWL (Instruction List, IL)

BU 0550 GB-0813

19

2.7 Program example

1. Comment to program function and the outline conditions for the program

e.g parameterise inverter for PLC control (the parameterisation must be carried out in the inverter.):

Parameter

P350

=

1

Control of the FI

via PLC

Parameter

P351

=

0

Control work and main setpoint

from the PLC

Parameter

P553[-01]

=

1

The

PLC setpoint 1

is defined as the

setpoint frequency

2. Definition of the variables and process values used in the PLC

_5_State_digital_input

Status of the digital inputs

_7_Analog_input1

Value of analog input 1

_21_PLC_set_val1

PLC

– setpoint 1

Run

Instance of the Motion Control module "MC_Power" (name freely selectable)

3. Program sequence

Command

Meaning

Example

LD

_5_State_digital_input

.0

Reads

the

status of the digital inputs

and loads the

value of

digital input 1

into the accumulator

Digital input 1: high Accumula-

tor = 1

ST

Run

.Enable

Saves

the value from the accumulator in the Mo-

tion Control block called up by the variable

Run

as

the value for

Enable

.

Enable = 1

LD

_7_Analog_input1

Reads

the value of

analog input 1

(Standardisation:

10 V = 1000) and loads it into the accumulator

AIn1 = 2.5 V accumulator = 250

SUB

int#500

Subtracts

the

integer value 500

from the accumu-

lator (shifts the 0-point from 0 to 5 V)

250 - 500 = Accumulator = - 250

MUL

int#32

Multiplies

the

integer value 32

with the accumula-

tor value ( Standardisation of the setpoint to the

value range of the FI (100 % = 4000

hex

≈

16000

dec

).

-250 * 32 = Accumulator = - 8000

dec

ST

_21_PLC_set_val1

Saves

the accumulator in the process variable

PLC-setpoint1

.

-8000

dec

setpoint - 50 %

(Setpoint 50 % of the maximum

frequency in the direction of rota-

tion to the left)

Cal

Run

The Motion Control function module for

setting the

output stage of the inverter

is executed

Output stage is enabled.