2 process image, 3 program task – NORD Drivesystems BU0550 User Manual

Page 10

PLC logic for NORD SK 54xE frequency inverters

10

BU 0550 GB-0813

In the flag memory, two different classes of variables are stored in the variable section:

[VAR]

Memory variables for storage of auxiliary information and statuses. Variables of this type are initialised every

time the PLC starts. The memory content is retained during the cyclic sequence of the PLC.

[VAR_ACCESS]

These are used to read and describe process data (inputs, outputs, setpoints, etc.) of the frequency inverter.

These values are regenerated with every PLC cycle.

1.2.2

Process image

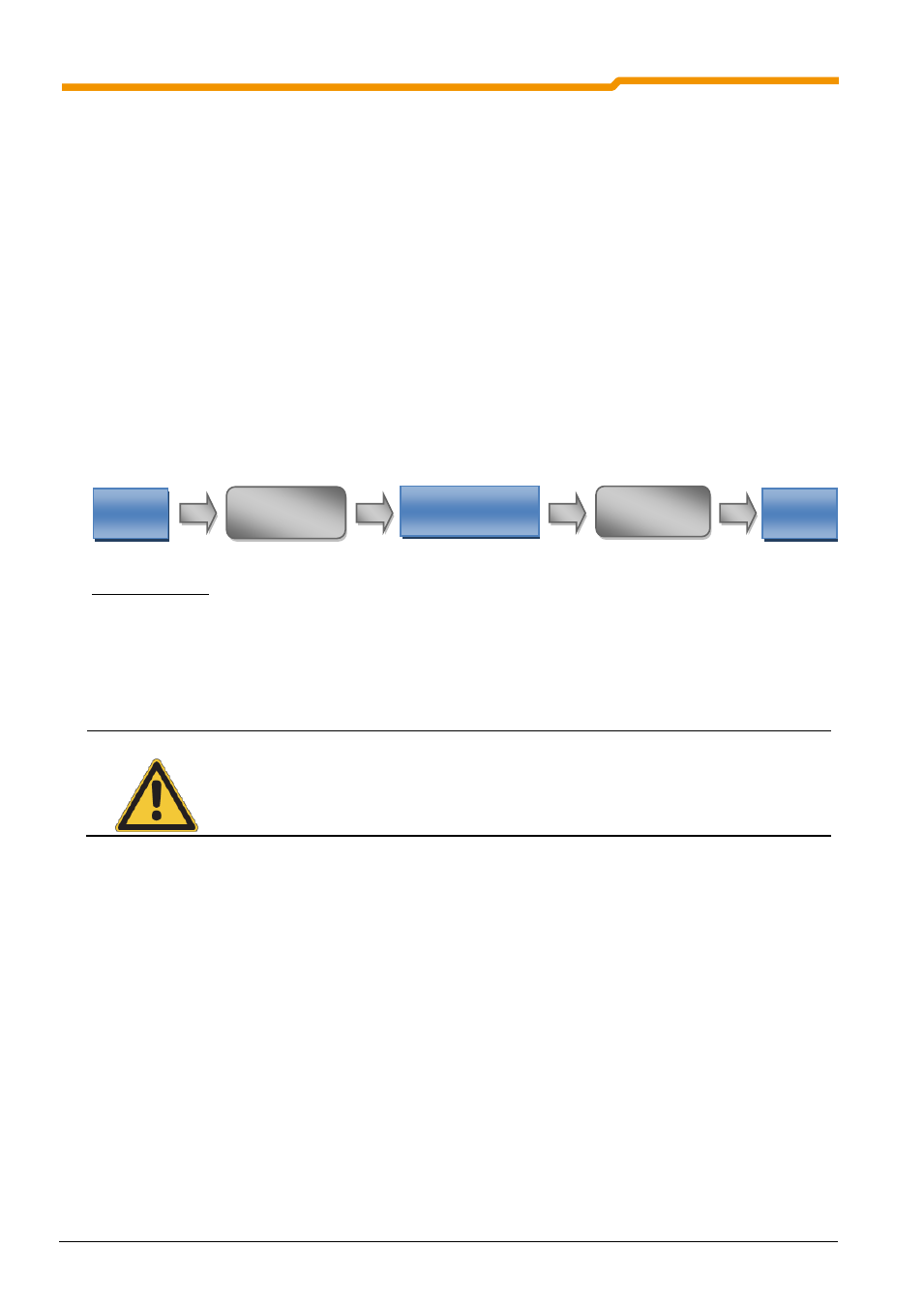

Several physical dimensions such as torque, speed, position, inputs, outputs etc. are available to the

inverter. These dimensions are divided into actual and setpoint values. They can be loaded into the process

image of the PLC and influenced by it. The required process values must be defined in the list of variables

under the class VAR_ACCESS.

With each PLC cycle, all of the process data for the inverter which is defined in the list of variables is newly

read in. At the end of each PLC cycle the writable process data is transferred back to the inverter. See the

following diagram.

Fig. 2 Process image

Because of this sequence it is important to program a cyclic program sequence. Programming loops in order

to wait for certain events (e.g. changes of input level) does not produce the required result.

This behaviour is different in the case of function blocks which access process values. Here, the process

value is read on call-up of the function block and the process values are written immediately when the block

is terminated.

NOTE

If the blocks MC_Power, MC_Reset, MC_MoveVe

locity, MC_Move…, MC_Home or MC_Stop

are used, the process values "PLC_Control_Word" and "PLC_Set_Val1" to "PLC_Set_Val5"

must not be used. Otherwise the values in the list of variables would always overwrite the

changes to the function block.

1.2.3

Program Task

Execution of the program in the PLC is carried out as a single task. The task is called up cyclically every 5

ms and its maximum duration is 3 ms. If a longer program cannot be executed in this time, the program is

interrupted and continued in the next 5 ms task.

Read in

process

values

PLC program

execution

Save process

values

Start of

cycle

End of

cycle