Manually tuning controllers, 12 manually tuning controllers – West Control Solutions 8700+ User Manual

Page 122

1

/

4

-DIN,

1

/

8

-DIN &

1

/

16

- DIN Controllers & Indicators - Product Manual

59305, Issue 7

– March 2014

Manual Tuning

Page 117

P

Input Span

T

6

12 Manually Tuning Controllers

Single Control Tuning (PID with Primary Output only)

This simple technique balances the need to reach setpoint quickly, with the wish to limit

setpoint overshoot at start-up or during process changes. It determines values for the

Primary Proportional Band (

) and Derivative Time

Constant (

) that allow the PID control algorithm to give acceptable results in most

applications that use a single control device.

CAUTION:

This technique is suitable only for processes that are not harmed by large

fluctuations in the process variable.

1. Check that the Setpoint Upper Limit (

) and Setpoint Lower Limit (

) are set to

safe levels for your process. Adjust if required.

2. Set the Setpoint to the normal operating value for the process (or to a lower value if

overshoots beyond this value might cause damage).

3. Select On-Off control (i.e. set

= 0).

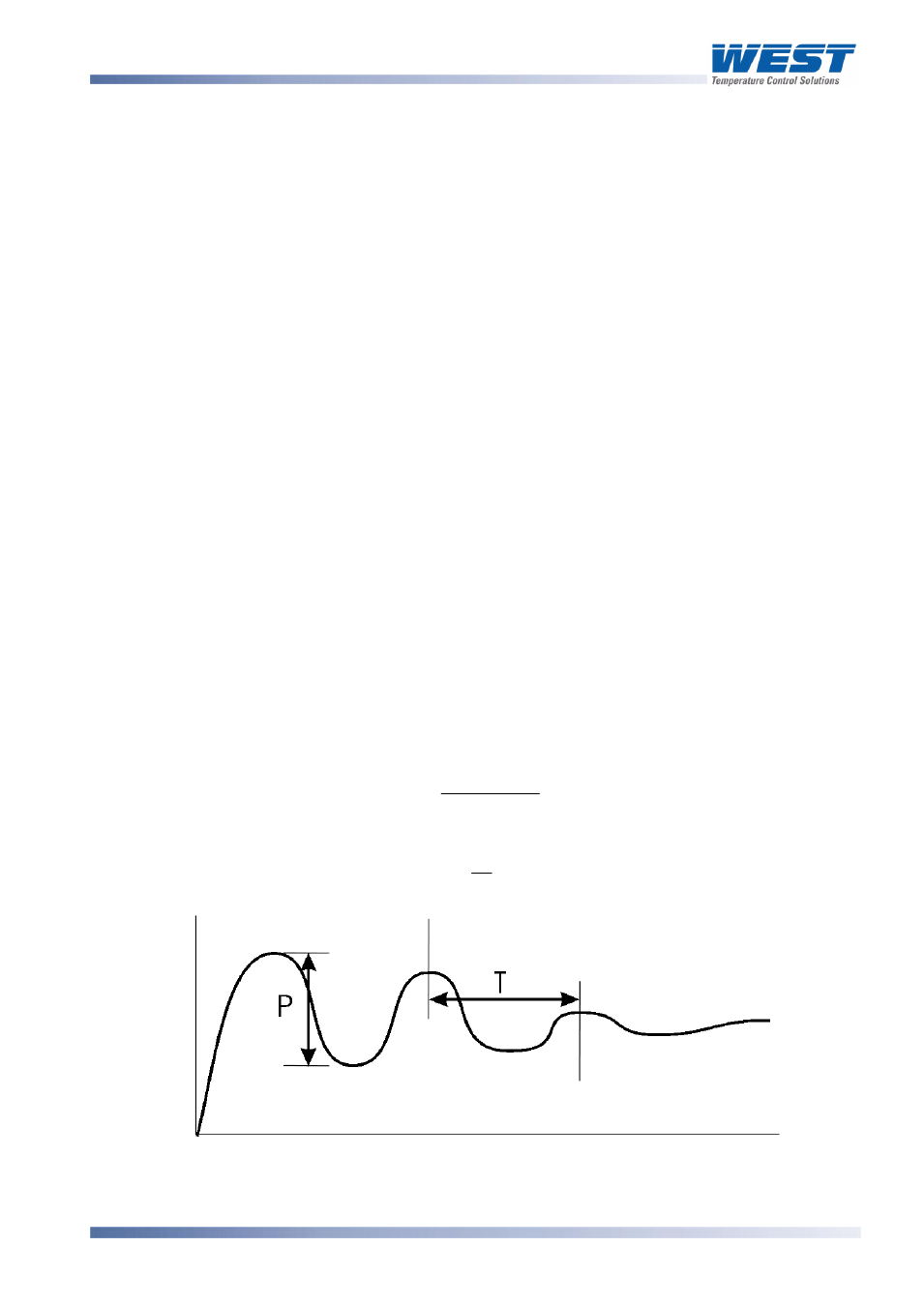

4. Switch on the process. The process variable will oscillate about the setpoint. Record the

Peak-to-Peak variation (P) of the first cycle (i.e. the difference between the highest value

of the first overshoot and the lowest value of the first undershoot), and the time period of

the oscillation (T) in minutes. See the example diagram below - Manually Tuning PID.

5. Calculate the PID control parameters using the formula below. Input Span is the difference

between Scale Range Lower Limit and Scale Range Upper Limit:

= x 100

= T minutes

= minutes

Figure 39.

Manually Tuning PID

Time

P

roce

ss

V

ari

ab

le