2 test equipment requirements, Table 4-2. suggested sense resistors, Test equipment requirements -3 – KEPCO BOP-GL 1KW Operator Manual Firmware Ver.3.05 and higher User Manual

Page 113: Suggested sense resistors -3, Voltage calibration measurements and tolerances -3, Ar. 4.3)

BOP-1K-GL 022814

4-3

4.2

TEST EQUIPMENT REQUIREMENTS

Table 4-2 lists sense resistors recommended for measuring current and includes Kepco and

Manufacturer’s part numbers. The value of the sense resistor chosen should be known with

0.001% accuracy. If other than a recommended sense resistor is to be used, it must be rated for

at least 100W power dissipation (actual power dissipation will be approximately 10W). The ther-

mal coefficient of the sense resistor chosen should be 10 ppm/°C or better. Other high-precision

and high-stability current measurement devices (such as a zero flux current transducer) can

also be used for output current calibration and evaluation.

The digital voltmeter (DVM) used to measure output voltage and the voltage across the current

sensing resistor should have at least six digits, multiple ranges, the smallest resolution must be

at least one microvolt and the accuracy must be at least 0.0001%.

To calibrate the external programming capabilities of the BOP a DC reference voltage with the

following minimum specifications is required.

•

Value: 0.0V ±0.1mV and 10.0V ±0.1mV (either positive and negative or floating)

•

Stability: better than 10

-5

•

Internal Impedance: better than 0.1 Ohms

•

Output Current: >0.5mA when sourcing, >0.15mA when sinking

4.3

CALIBRATION USING REMOTE SCPI COMMANDS VIA GPIB OR RS 232 INTERFACE

The primary means of adjustment are the

CAL:DATA

commands. Basically these commands

are fine and coarse adjustments, however there are slight differences in how they work for dif-

ferent types of calibrations.

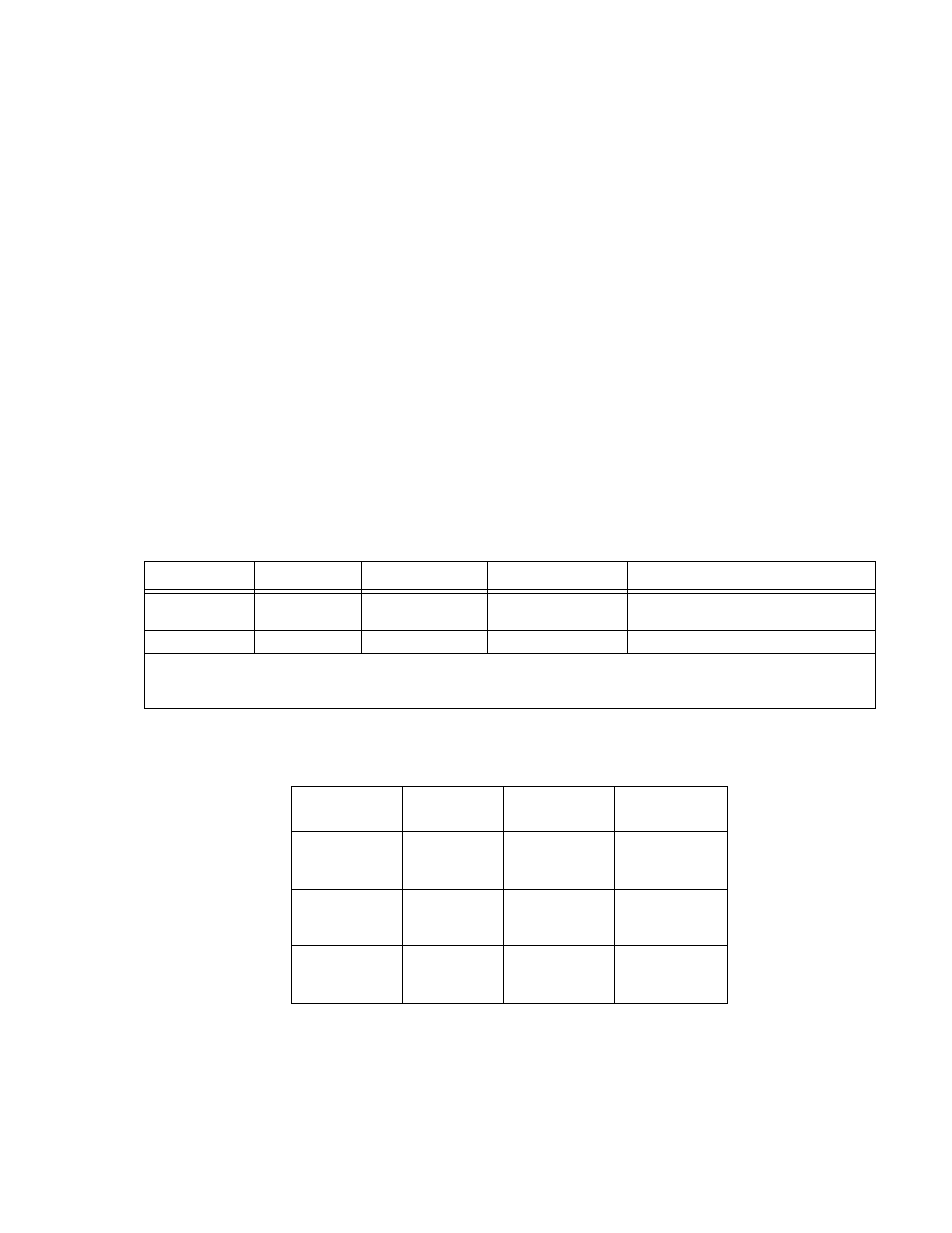

TABLE 4-2. SUGGESTED SENSE RESISTORS

MODEL

VALUE

KEPCO PART NO.

MANUFACTURER

MANUFACTURER PART NO.

BOP 10-100GL

BOP 20-50GL

0.001 OHM

115-3033

ISOTEK

RUG-Z-R001-0.1 TK10

BOP 50-20GL

0.01 OHM

115-2997

ISOTEK

RUG-Z-R010-0.1 TK10

NOTE: ALL SENSE RESISTORS MUST BE MOUNTED ON A HEATSINK WITH A MINIMUM SURFACE AREA OF 36 SQUARE

INCHES TO MAINTAIN THERMAL STABILITY DURING CALIBRATION; FORCED CCOOLING IS RECOMMENDED.

KEPCO HEATSINK P/N 136-0451 WILL PROVIDE ADQUATE COOLING FOR THE SENSE RESISTOR.

TABLE 4-3. VOLTAGE CALIBRATION MEASUREMENTS AND TOLERANCES

MODEL

VOLTAGE

ZERO

±FULL SCALE

VOLTAGE

±FULL SCALE

VPR LIMIT

BOP 10-100GL

0V

±0.0001V

10V (MAX)

-10V (MIN)

±0.001V

10V (MAX)

-10V (MIN)

±0.003V

BOP 20-50GL

0V

±0.0002V

20V (MAX)

-20V (MIN)

±0.002V

20V (MAX)

-20V (MIN)

±0.006V

BOP 50-20GL

0V

±0.005V

50V (MAX)

-50V (MIN)

±0.005V

50V (MAX)

-50V (MIN)

±0.015V