Aquametrix SHARK-120/240 Controllers User Manual User Manual

Page 11

S

H

A

R

K

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

Section 3 - Electrical Connections and Setup

Section 3 - Electrical Connections and Setup

Page 9

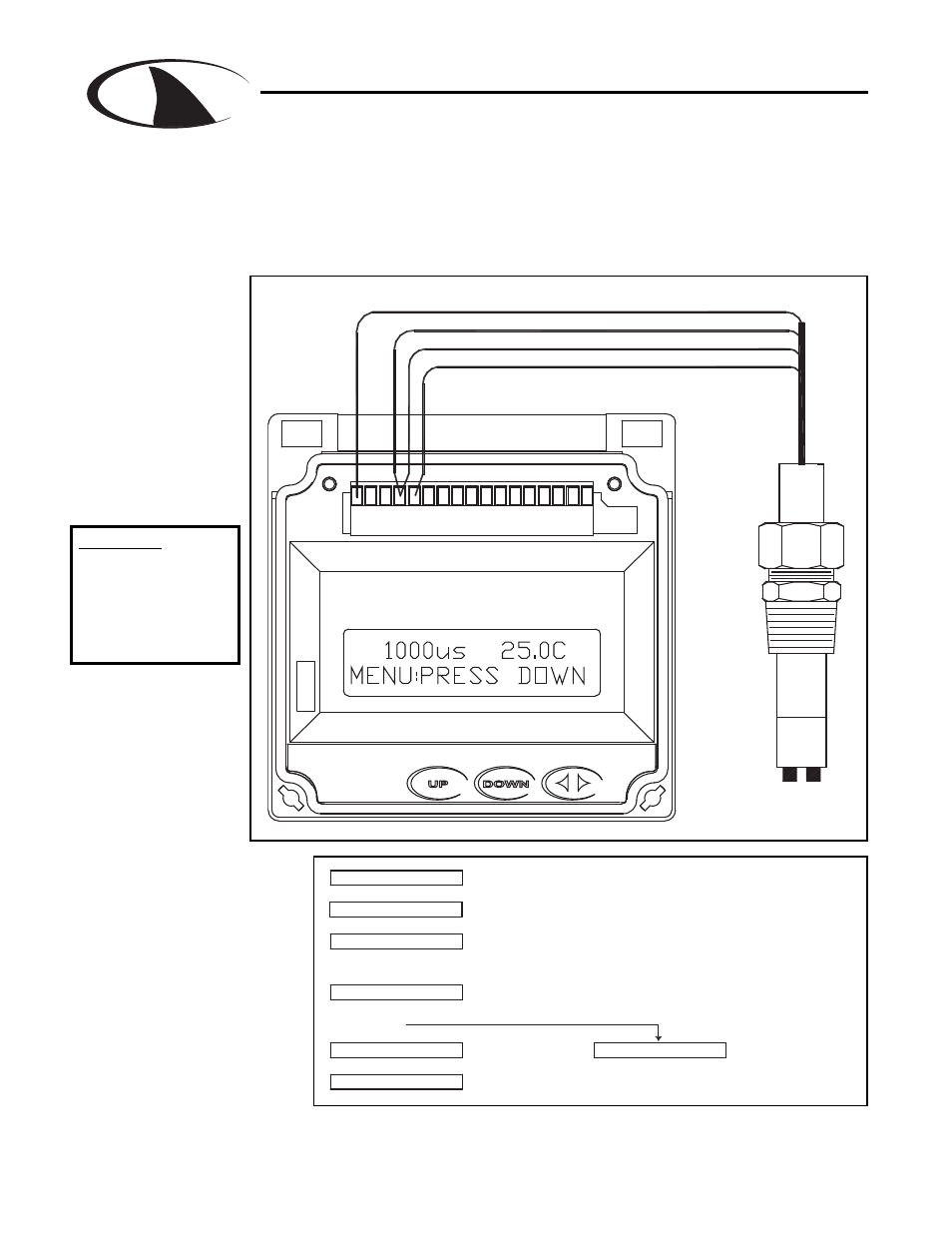

3.5 Conductivity Cell (Contacting style) connections and setup

WHITE (CELL) (1)

BLACK (CELL) (4)

RED (TEMP. SENSOR) (4)

GREEN (TEMP. SENSOR) (5)

P6

8

1 2 3 4

6

5

7

10

9

11 12 13 14 15 17

16

CONTACTING

CONDUCTIVITY

CELL

Figure 3.4 Connections for Conductivity Cells

SET TEMPERATURE COMPENSATION

3Kohm NTC (thermistor)

1Kohm RTD

ENSURE SENSOR IS CORRECT TYPE

SEC. 6.7

SELECT CONDUCTIVITY RANGE

SELECT COND METER

SEC. 6.13

OR

FOR PROCESS

SEC 6.9

SEC. 6.6

1000uS 25.0C

MANUAL CAL COND

TEMP COMP CURVE

TEMP SENSOR

COND RANGE

METER SELECTION

CALIBRATE WITH

RUN MODE

REFERENCE SOLUTIONS

SEC 6.1

DRY CAL COND

CALIBRATE WITH FACTORY

SPECIFIED CELL CONSTANT

SEC 6.2

Once connnected, step

through the LCD menus to

select the cell in the order

shown. The TEMP COMP

CURVE setup default is

1.8%/deg C. This is accept-

able for most process appli-

cations. If your process is

significantly different from

this, change the setting in

the TEMP COMP CURVE

menu.

The drawing shows the connections for the Aquametrix Conductivity Cells (Contacting style). The cable

should be run in a conduit seperate from the AC power wires, and via a seperate conduit hole. The cell

cable length should not exceed 300ft. (91 meters).

Note: Leave 4” to 6”

slack for all wires

connected to the

terminals of P6.

Slack required so

that wires do not

interfere with open-

ing or closing of the

front door.

Dwg# N104-36

CAUTION:

Always remove line

power before

unplugging or

plugging in the P6

connector