2 normal operation, 1 starting operation, 2 corrective actions in case of failure – Yokogawa GD40 Gas Density Detector User Manual

Page 51: Normal operation -8 3.2.1, Starting operation -8, Corrective actions in case of failure -8

<3. Operation>

3-8

IM 11T3E1-01E

3.2

Normal Operation

In normal operation, there is no need for working with the GD402 analyzer except when calibrat-

ing it. Unless there is any failure found, carry out maintenance, inspection, and so on at the same

time the analyzer is calibrated. The analyzer is designed to prohibit you from calibrating it or set-

ting each parameter unless you have entered the password (XXX).

(See section “4.2 Setting Lists”.)

3.2.1

Starting Operation

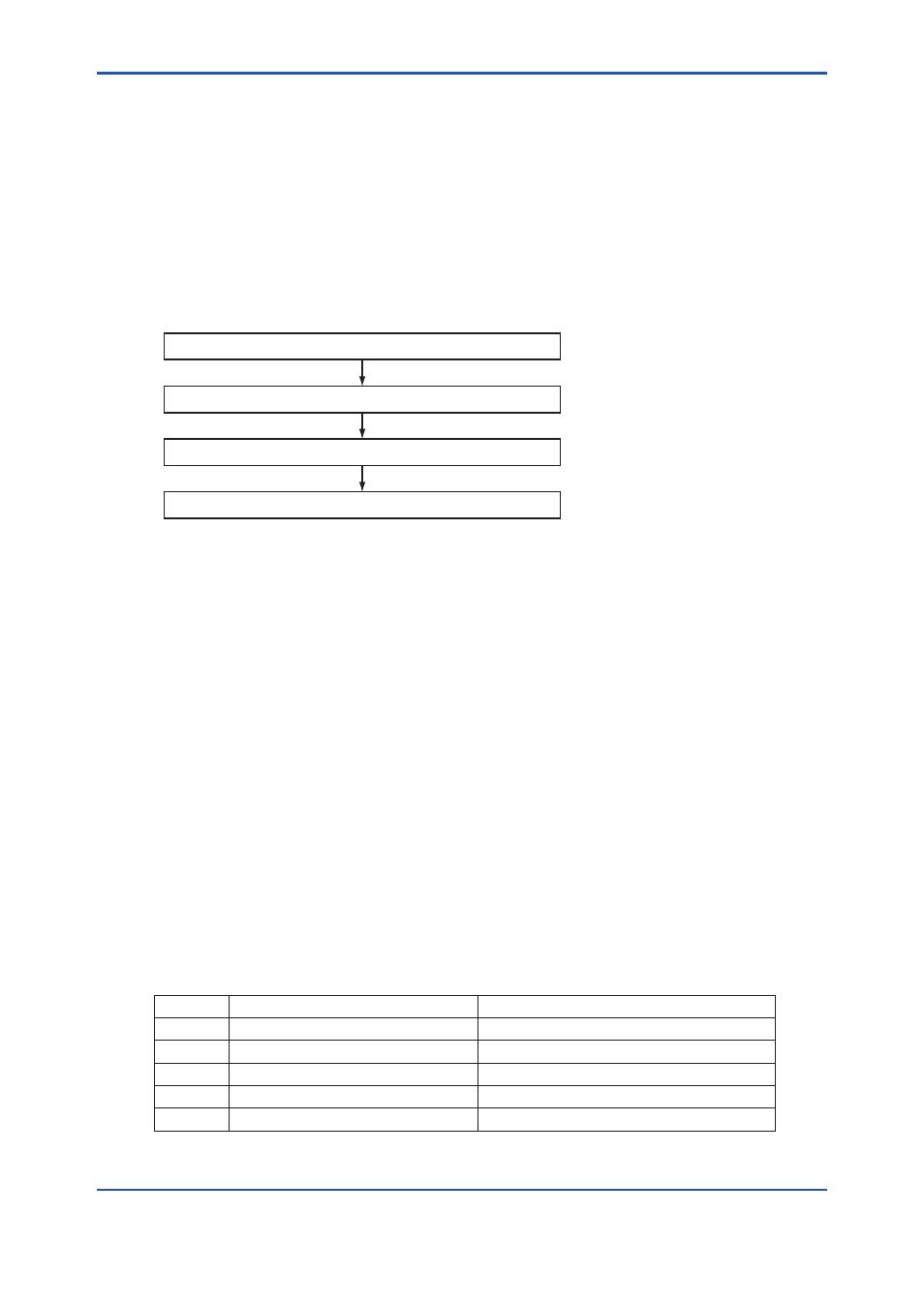

Follow the procedure below to start operation.

Completing these steps return to the

Turn on the external power switch.

Set the operating parameters.

Calibrate the analyzer for correct zero and span setpoints.

F0307.ai

The following details the operations required in this procedure.

(1) The analyzer, when turned on, indicates the density value. See Figure 5.2, 6.3 or 7.3 for the

operations used to change to the required unit of density.

(2) Set the relevant operating parameters by checking and modifying their default values in

order to meet individual operating requirements.

(3) Supply the zero and span gases to check readings. If the readings contain errors, the ana-

lyzer must be calibrated. For details on calibration, see Chapter 8, 9 or 10.

(4) When calibration is complete, the analyzer returns to the

3.2.2

Corrective Actions in Case of Failure

If the GD402 analyzer senses a failure, it sends out a FAIL contact output signal through ter-

minals 18 and 19. In such a case, the output signal is held at either the value held immediately

before or at the preset value for each setting.

The message field indicates the type of error by the error code. Should a failure occur, check the

nature of the failure and take corrective action without delay. Table 3.1 summarizes the numeric

codes of errors that may occur in the measurement mode. For details on each type of error, see

Table 11.2 on page 11-4.

Table 3.1 Errors that May Occur in the Measurement Mode

Error No.

Nature of Failure

Corrective Actions

Err. 01

Sensor oscillation shutdown

Reset the power and contact service personnel.

Err. 02

Faulty oscillation frequency of sensor

Reset the power and contact service personnel.

Err. 03

Sensor’s failure to detect temperature

Contact service personnel.

Err. 04

Failure in A/D converter

Contact service personnel.

Err. 05

Failure in memory

Contact service personnel.