2 piping for system configuration 2, 1 piping parts for system configuration 2, Piping for system configuration 2 -3 – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 59: Piping parts for system configuration 2 -3, Piping in system 2 is illustrated in figure 4.7

IM 11M12A01-05E

4-3

4. Piping

4.2 Piping for System Configuration 2

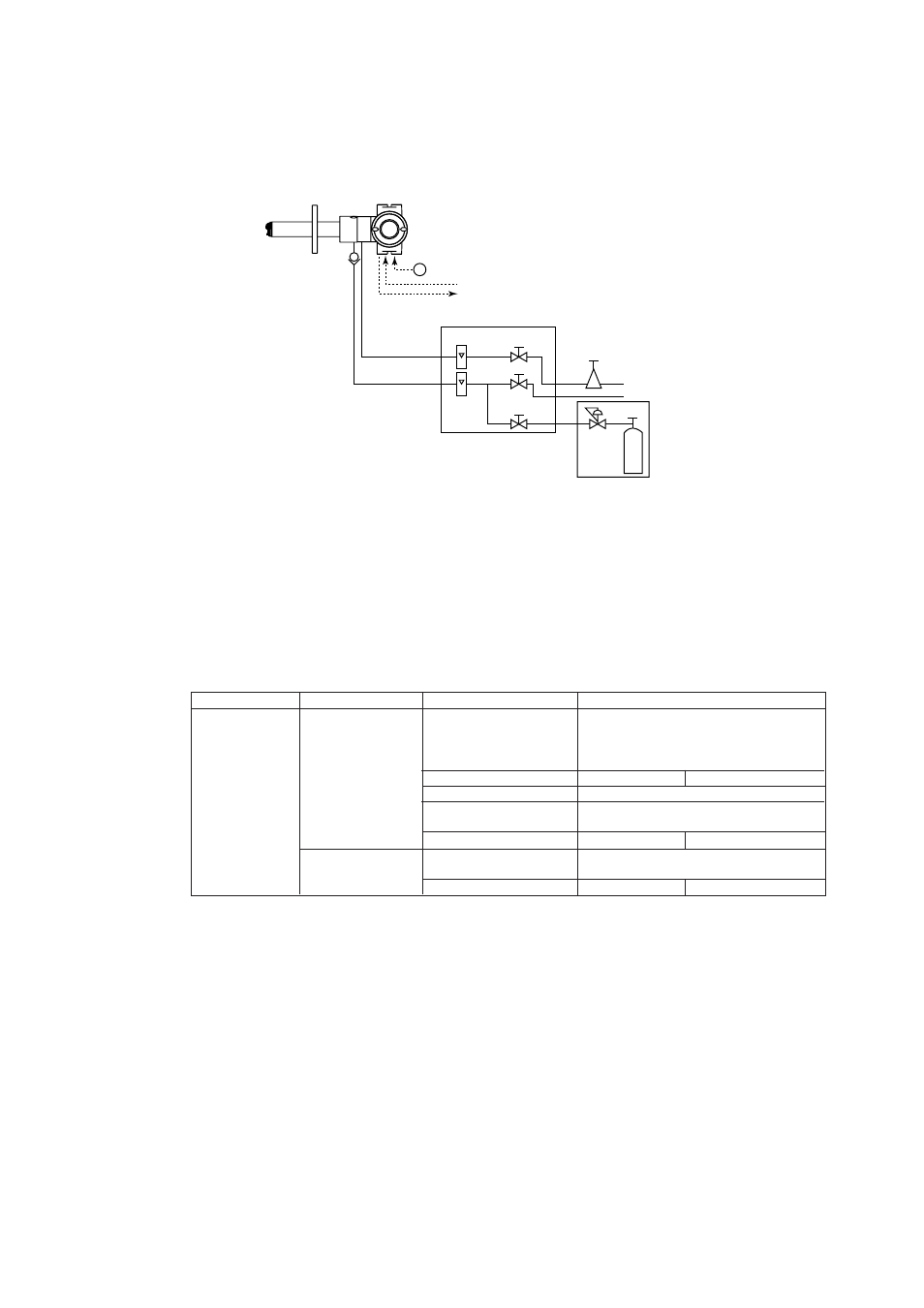

Piping in System 2 is illustrated in Figure 4.7.

~

F4.7E.EPS

Model ZA8F flow setting unit

Reference gas

Calibration gas

Needle

valve

Flowmeter

Instrument air

Air Set

Calibration gas pressure regulator

Zero gas

cylinder

Calibration gas unit case

Stop valve

or

Check valve

100 to 240 V AC

Model ZR202G Integrated type Zirconia

High Temperature Humidity Analyzer

Span gas (Same as Zero gas

Calibration unit )

Contact input

Analog output, Contact output

Digital output (HART)

Figure 4.7 Piping for System 2

System 2 illustrated in Figure 4.7 requires piping as follows:

• Mount the stop valve or the check valve through a nipple to the reference gas inlet of

the equipment.

4.2.1 Piping Parts for System Configuration 2

Check that the parts listed in Table 4.2 are provided.

Table 4.2 Piping Parts

Equipment

Piping location

Parts

Description

General-use

Calibration gas inlet Stop valve or check valve

Stop valve (L9852CB or G7016XH

Analyzer

provided by YOKOGAWA),

check valve (K9292DN or K9292DS)

recommended by YOKOGAWA

Nipple *

Rc1/4 or 1/4 NPT Commercially available

Zero gas cylinder

User´s scope

Regulator valve

(G7013XF or G7014XF) recommended by

YOKOGAWA

Joint for tube connection

Rc1/4 or 1/4 NPT Commercially available

Reference gas inlet

Air set

(K9573XH/K9473XJ or G7004XF/K9473XG)

recommended by YOKOGAWA

Joint for tube connection

Rc1/4 or 1/4 NPT Commercially available

Note: Parts marked with * are used when required.

T4.2E.EPS