2 piping for system, 2 piping for system 2 – Yokogawa Single Channel Oxygen Analyzer System ZR22/ZR402 User Manual

Page 76

IM 11M13A01-02E

4-7

4. Piping

4.2

Piping for System 2

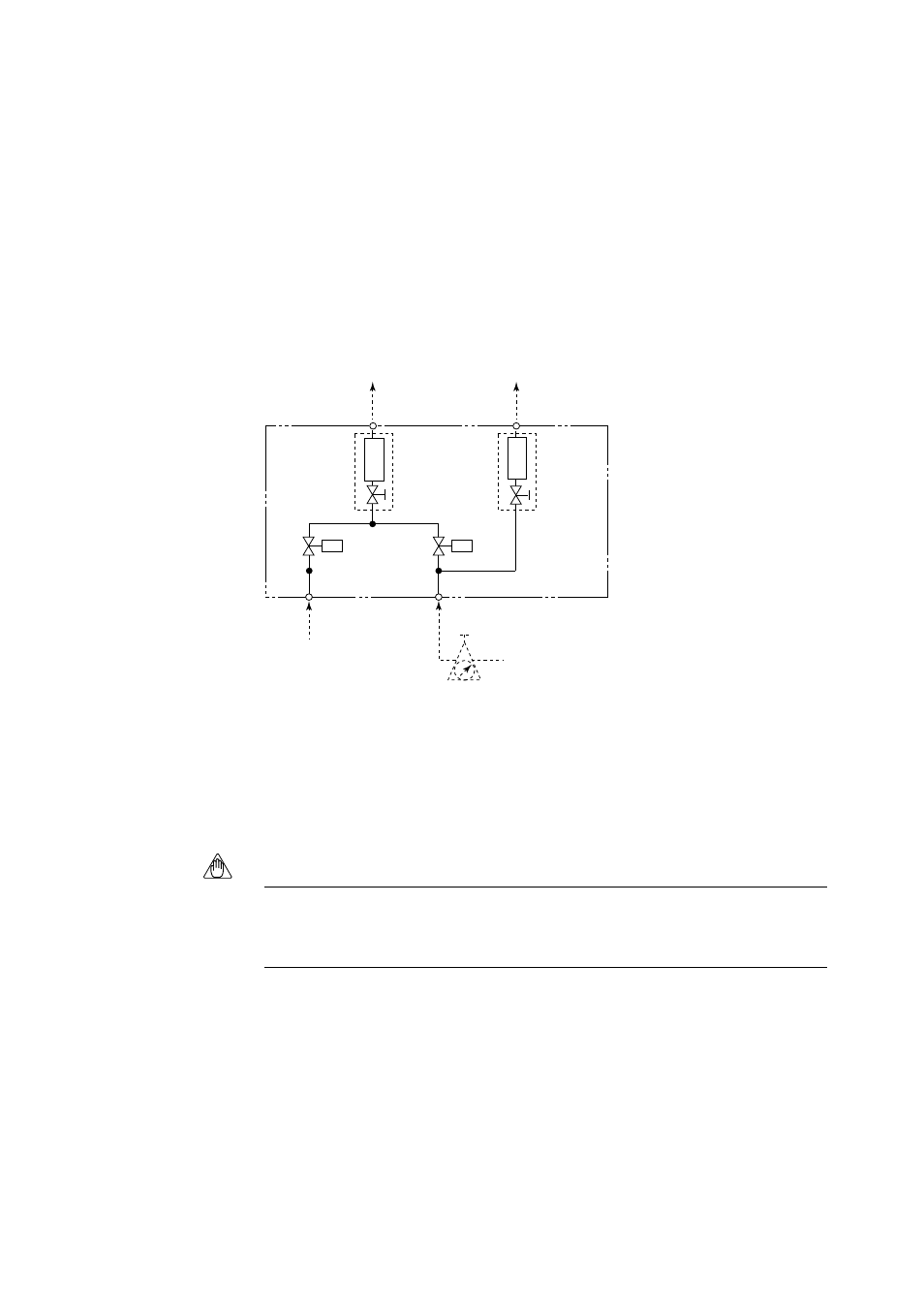

Piping in System 2 is illustrated in Figure 4.7. In System 2, calibration is automated;

however, the piping is basically the same as that of System 1. Refer to Section 4.1.

Adjust secondary pressure of both the air set and the zero gas reducing valve so that

these two pressures are approximately the same. The flow rate of zero and span gases

(normally instrument air) are set by a single needle valve.

After installation and wiring, check the calibration contact output (see Sec. 7.11.2), and

adjust zero gas reducing valve and calibration gas needle valve so that zero gas flow is

within the permitted range. Next check span gas calibration contact output and adjust

air set so that span gas flow is within the permitted range.

CHECK

OUT

ZERO GAS IN

AIR IN

Instrument air Approx.

1.5 l/min.

flow

meter

flow

meter

REF

OUT

*

*

EV1

EV2

Air set

F4.6E.EPS

*: Needle valve comes with flowmeter

Figure 4.6 ZR40H Autcalibration unit piping diagram

If the contact input to the converter is used for the blowback function, prepare blowback

piping according to Section 4.2.

Note

Blowback function means the function to get rid of dust inside a probe in a high-

temperature probe adapter by using compressed air, when a high-temperature detector is

used.