3 operating the zero gas flow setting valve, 4 operation after calibration – Yokogawa Single Channel Oxygen Analyzer System ZR22/ZR402 User Manual

Page 171

IM 11M13A01-02E

10-20

10.6.3

Operating the Zero Gas Flow Setting Valve

Operate the zero gas flow setting valve during zero-point calibration in the following

procedures:

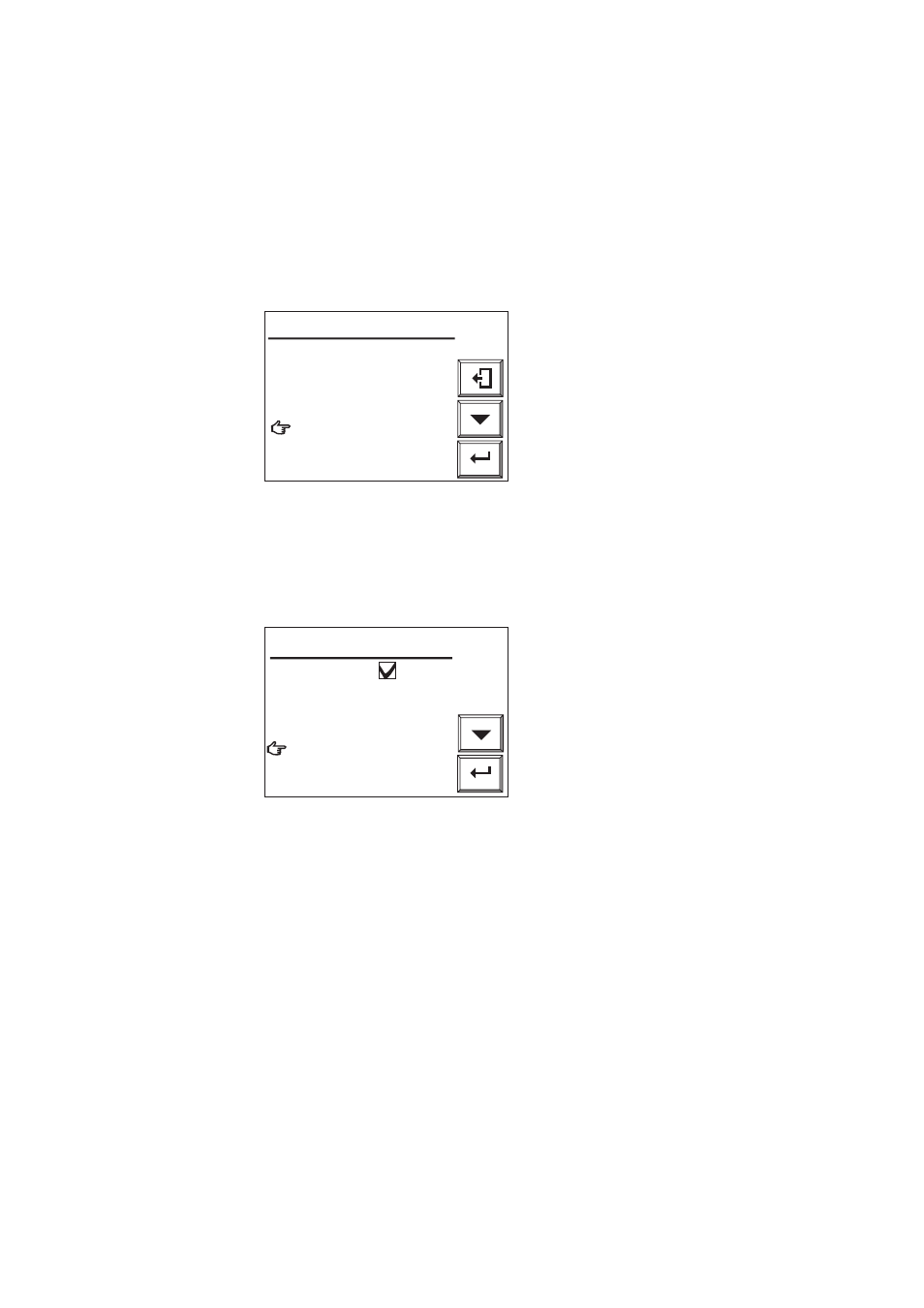

(1) When the display shown in Figure 10.17 appears during calibration, open the zero

gas flow setting valve of the flow setting unit and adjust the flowrate to 600

±

60

ml/min. To rotate the valve shaft, if the valve has a lock nut loosen the lock nut and

slowly turn it counterclockwise. To check the flowrate, monitor the calibration gas

flow meter.

Enter

Open zero gas valve.

Set flow span gas to

600ml/min.

Valve opened

᭜

Cancel calibration

Manual calibration

F10.17E.EPS

Figure 10.17 Manual Calibration Display

(2) Adjust the flowrate and select Valve opened from the Manual calibration display.

Check the Trend graph display to see that the measured value is stabilized. Then

press the [Enter] key. The Manual calibration display shown in Figure 10.18 appears.

Enter

Zero calibration

Close the zero gas valve.

Span calibration

᭜

End

Manual calibration

F10.18E.EPS

Figure 10.18 Zero-point Calibration Complete (in Manual Calibration)

(3) Close the zero gas flow setting valve to stop the zero gas flow. If the valve has a

lock nut, be sure to tighten the lock nut to prevent the any leakage of the zero gas

into the sensor because the valve may become loose during measurement.

10.6.4

Operation After Calibration

No special operation of the instrument is needed after calibration. However, it is

recommended that the pressure regulator for the zero gas cylinders be closed because

calibration is not required so often.