Troubleshooting – Watlow Series SD PID Profiling Controller User Manual

Page 77

Wa t l o w S e r i e s S D

•

7 5

•

C h a p t e r 1 O v e r v i e w

Wa t l o w S e r i e s S D

•

7 5

•

C h a p t e r 1 2 F e a t u r e s

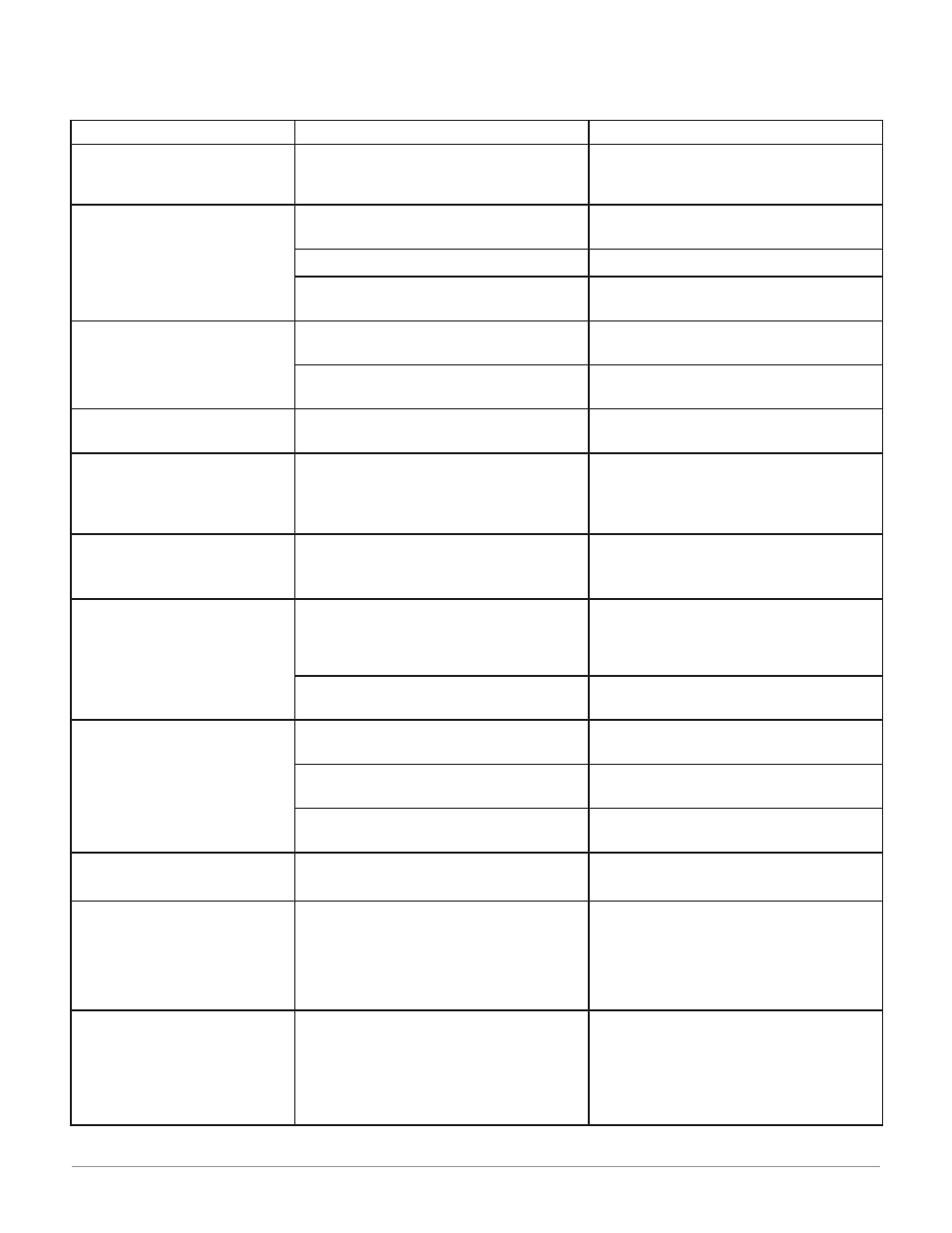

Indication

Probable Cause

Corrective Action

Getting alarm message

[

A1hi]

,

[A2hi]

,

[A3hi]

,

[A1Lo]

,

[

A2Lo]

or

[A3Lo]

.

The process value is beyond an alarm set

point.

Determine when alarms messages will dis-

play and the proper response to an alarm

message.

Alarm is occurring when it should

not.

Alarm settings are incorrect.

Adjust the alarm settings to be correct for

the application.

Input may be in an error condition.

See error messages.

Alarm may be latched.

Press the Infinity Key

ˆ

to unlatch an

alarm.

Alarm output indication is incor-

rect.

Alarm settings are incorrect.

Adjust the alarm settings to be correct for

the application.

Alarm may be silenced.

See the Features chapter for information on

alarm silencing.

Alarm is not occurring when it

should.

Alarm settings are incorrect.

Adjust the alarm settings to be correct for

the application.

Output cycles (turns on and off)

too frequently.

Wrong control mode. PID control selected in-

stead of On-Off control.

The cycle time is not set properly.

Select On-Off control mode (

[ht;m]

or

[CL;m]

Operations Page) and set the desired

hysteresis value.

Adjust the cycle time.

Controller does not control close

enough to the set point.

Wrong control mode. On-Off control selected

instead of PID.

PID is not tuned properly.

Select PID control and perform tuning.

Run autotune or perform manual tuning.

Controller’s process value reading

is decreasing but actual process is

increasing.

Thermocouple polarity is reversed.

Check thermocouple connections. All thermo-

couple connections, including thermocouple

extension wire, must maintain the correct

polarity for proper operation.

Analog voltage or analog current input scal-

ing is reversed or incorrect.

Check the settings of the analog output scale

low and scale high parameter (Setup Page).

Parameter(s) do not appear.

Parameter is not active.

See Setup and Operation chapters to deter-

mine when parameters should appear.

Parameter lockout is active.

Set the correct level of lockout for access

(Setup Page).

Operations Page is not configured properly.

Select the desired parameters for the Pro-

gramming Page.

Cannot access Operation Page.

Cannot change the set point.

Parameter lockout is active.

Set the correct level of lockout for access

(Setup Page).

Profile will not start or resume.

Lower display flashes between

static set point value and File

Number / Step Number. For

example, if File 1, Step 1 is not

valid, the display will flash 1.1.

Profile step has target set point or Wait-for

Process values that are outside of

[SP;lo]

or

[SP;hi]

values.

Jump Loop step is trying to jump to itself.

Keep target set point or Wait-for Process val-

ues inside set point limits or adjust set point

limits.

Correct Jump Loop step (cannot jump to

itself).

Profile takes more time to com-

plete than what is programmed.

[`gSd]

flashes in the lower dis-

play.

Guaranteed Soak Deviation is enabled. The

program will stop the count down time until

the process value returns to within the de-

viation window. The

[~gsd]

value may be too

small.

If Guaranteed Soak Deviation function isn’t

required, set

[GS;dE]

to

[~~no]

to disable it.

If Guaranteed Soak Deviation function is

required, increase

[~gSd]

value to reduce the

amount of time the process is outside of the

deviation window.

Troubleshooting