Control methods, High scale and low scale, High range and low range – Watlow Series SD PID Profiling Controller User Manual

Page 68: Output configuration, Auto (closed loop) and manual (open loop) control

Wa t l o w S e r i e s S D

•

6 6

•

C h a p t e r 1 2 F e a t u r e s

High Scale and Low Scale

When an analog input is selected as process voltage or

process current input, you must choose the value of volt-

age or current to be the low and high ends. For example,

when using a 4 to 20 mA input, the scale low value would

be 4.00 mA and the scale high value would be 20.00 mA.

Commonly used scale ranges are: 0 to 20 mA, 4 to 20 mA,

0 to 5V, 1 to 5V and 0 to 10V.

The Series SD allows you to create a scale range for

special applications other than the standard ones listed

above. Reversing of the scales from high values to low

values is permitted for analog input signals that have a

reversed action. For example, 50 psi = 4 mA and 10 psi =

20 mA.

Select the low and high values with Process Scale

Low

[Sc;Lo] and Process Scale High [Sc;hi] (Setup

Page).

High Range and Low Range

With a process input, you must choose a value to

represent the low and high ends of the current or volt-

age range. Choosing these values allows the controller’s

display to be scaled into the actual working units of mea-

surement. For example, the analog input from a humidity

transmitter could represent 0 to 100 percent relative hu-

midity as a process signal of 4 to 20 mA. Low scale would

be set to 0 to represent 4 mA and high scale set to 100

to represent 20 mA. The indication on the display would

then represent percent humidity and range from 0 to 100

percent with an input of 4 to 20 mA.

Select the low and high values with Units Scale Low

[rg;Lo] and Units Scale High [rg;hi] (Setup Page).

Control Methods

Output Configuration

Each controller output can be configured as a heat

output, a cool output, an alarm output or deactivated. No

dependency limitations have been placed on the available

combinations. The outputs can be configured in any com-

bination. For instance, all three could be set to cool.

Analog outputs can be scaled for any desired current

range between 0 and 20 mA or voltage range between 0

to 10V. The ranges can be reversed to high-to-low for re-

verse acting devices.

Heat and cool outputs use the set point and Opera-

tions parameters to determine the output value. All heat

and cool outputs use the same set point value. Heat and

cool each have their own set of control parameters. All

heat outputs use the same set of heat control parameters

and all cool outputs use the same set of cool output pa-

rameters.

Each alarm output has its own set of configuration

parameters and set points, allowing independent opera-

tion.

Auto (closed loop) and Manual (open loop) Control

The controller has two basic modes of operation, auto

mode and manual mode. Auto mode allows the control-

ler to decide whether to perform closed loop control or to

follow the settings of the Input Error Failure Mode pa-

rameter (Setup Page). The manual mode only allows open

loop control. The Series SD controller is normally used in

the auto mode. The manual mode is usually only used for

specialty applications or for troubleshooting.

Manual mode is open loop control that allows the user

to directly set the power level to the controller’s output

load. No adjustments of the output power level occur

based on temperature or set point in this mode.

In auto mode, the controller monitors the input to

determine if closed loop control is possible. The controller

checks to make certain a functioning sensor is providing

a valid input signal. If a valid input signal is present, the

controller will perform closed loop control. Closed loop

control uses a process sensor to determine the difference

between the process value and the set point. Then the

controller applies power to a control output load to re-

duce that difference.

If a valid input signal is not present, the controller

will indicate an input error message

[Er;In] and then

use the Input Error Failure Mode

[FAIL] setting to de-

termine operation. You can choose to have the controller

perform a “bumpless” transfer, switch power to output a

preset manual level, or turn the output power off.

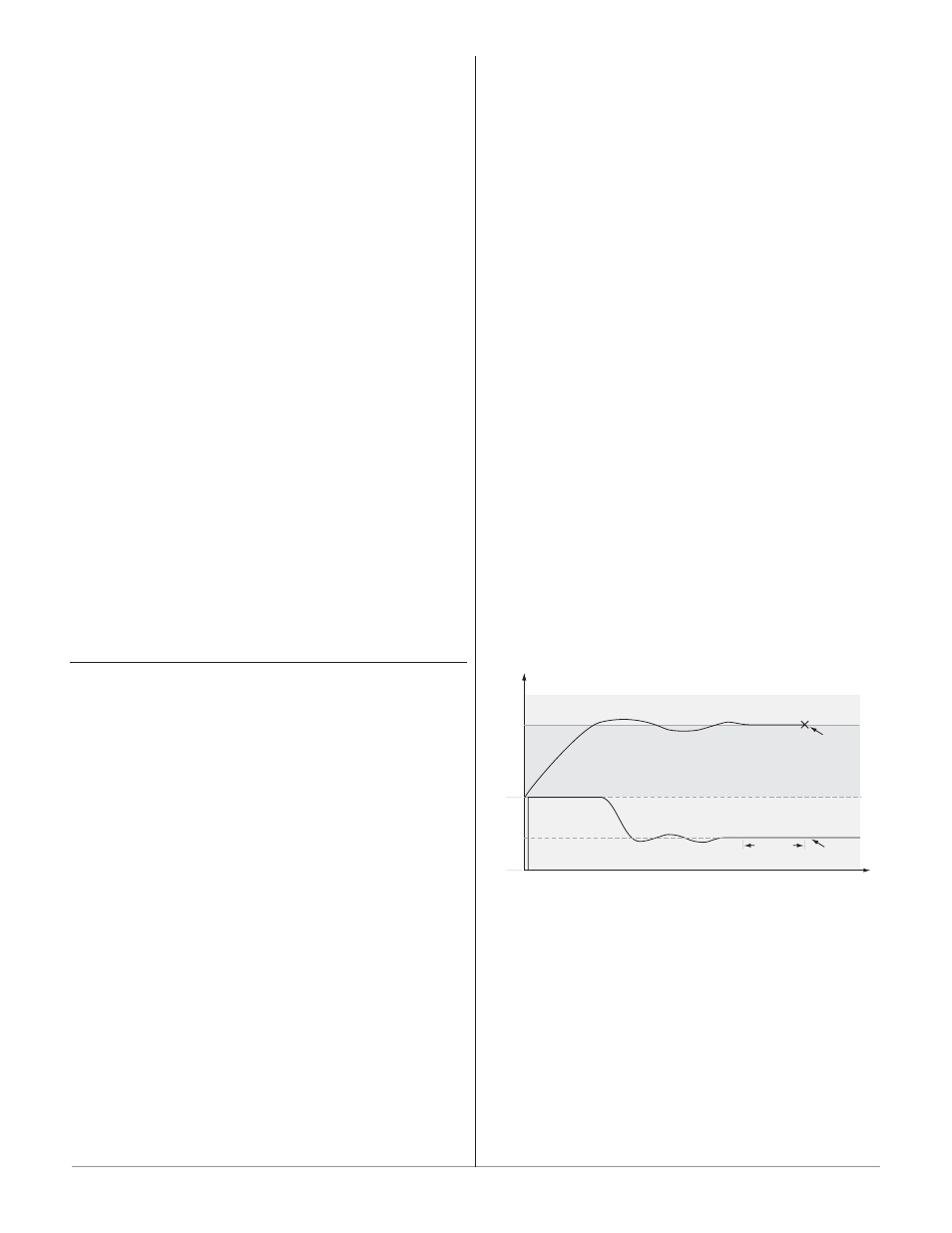

Bumpless transfer will allow the controller to transfer

to the manual mode using the last power value calculat-

ed in the auto mode if the process had stabilized at a ±5

percent output power level for two minutes prior to sen-

sor failure, and that power level is less than 75 percent.

Time

Te

mperature

40%

Sensor

Break

2 minutes

Locks in

Output

Power

0%

Set Point

Actual Temperature

Output Power

Power

100%

Input Error Latching

[I;Err] (Setup Page) deter-

mines the controller’s response once a valid input signal

returns to the controller. If latching is on

[`Lat], then

the controller will continue to indicate an input error

until the error is cleared. To clear a latched alarm, press

the Infinity Key ˆ. If latching is off [nLAt], the control-

ler will automatically clear the input error and return

to reading the temperature. If the controller was in the

auto mode when the input error occurred, it will resume

closed loop control. If the controller was in manual mode

when the error occurred, the controller will remain in

open loop control.

The Auto-Manual Control Indicator Light % is on

when the static set point controller is in the manual