Tuning the pid parameters, Autotuning, Manual tuning – Watlow Series SD PID Profiling Controller User Manual

Page 65: Tru-tune+™ adaptive control

Wa t l o w S e r i e s S D

•

6 3

•

C h a p t e r 1 2 F e a t u r e s

change the selected parameter in the top display. If you

do not want a parameter to appear for that location, se-

lect

[nonE]. To change the other 19 selections, press the

Advance Key ‰ to select a place in the page, [``P1] to

[`p20] ( [~P23] for the profiling version), in the bottom

display and use the Up ¿ or the Down ¯ key to change

the parameter selected in the top display.

Changes made to the Operations Page will persist un-

til changed by the operator or defaulted by full defaults

or user defaults. User-defined parameters are not over-

written by default parameters if those features become

enabled. Only parameters supported by a controller’s

particular hardware configuration and programming set-

tings will appear.

Tuning the PID Parameters

Autotuning

The autotuning feature allows the controller to mea-

sure the system response to determine effective settings

for PID control. When autotuning is initiated the control-

ler reverts to on-off control. The temperature must cross

the Autotune Set Point four times to complete the auto-

tuning process. Once complete, the controller controls at

the normal set point, using the new parameters.

To initiate an autotune, set Autotune

[`Aut] (Opera-

tions parameters) to

[``On]. A profile can’t be running.

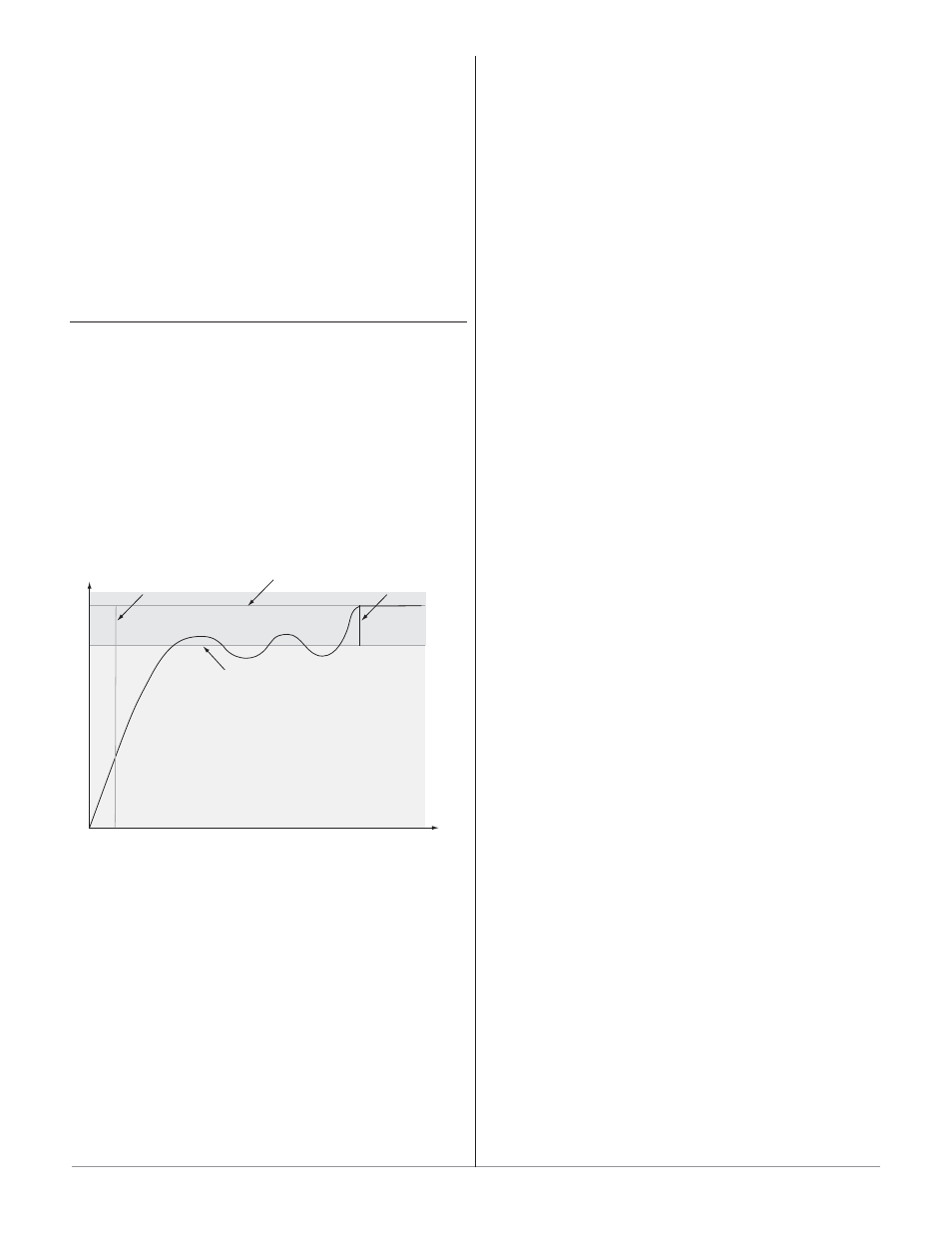

Time

Temperature

Autotune begins

Process Set Point

Autotune Set Point

(90 percent of Process Set Point)

Autotune complete

Manual Tuning

In some applications, the autotune process may not

come up with PID parameters that provide the process

characteristics you desire. If the autotune does not

provide satisfactory results, you will have to perform a

manual tune on the process:

1. Apply power to the Series SD and establish a set

point typically used in your process. If the control-

ler includes the TRU-TUNE+™ option (SD_E-_ _ _

_ - _ _ _ _), set TRU-TUNE+™ Enable to

[`~no].

2. Go to the Operations Page, and establish values

for the PID parameters: Proportional Band = 5;

Reset* = 0.00; Rate* = 0.00. Autotune should be

set to off.

3. When the system stabilizes, watch the process

value. If this value fluctuates, increase the propor-

tional band setting until it stabilizes. Adjust the

proportional band in 3° to 5° increments, allowing

time for the system to stabilize between adjust-

ments.

4. When the process has stabilized, watch the per-

cent power,

[Po;ht] or [Po;Cl]. It should be stable

±2%. At this point, the process temperature should

also be stable, but it will have stabilized before

reaching set point. The difference between set

point and actual can be eliminated with reset.

5. Start with a reset* value of 0.01 (99.99)** and

allow 10 minutes for the process temperature to

get to set point. If it has not, double (halve) ** the

setting and wait another 10 minutes. Continue

doubling (halving) ** every 10 minutes until the

process value equals the set point. If the process

becomes unstable, the reset* value is too large

(small) **. Decrease (increase) ** the reset value

until the process stabilizes.

6. Increase Rate* to 0.10 minute. Then increase the

set point by 11° to 17°C. Monitor the system’s

approach to the set point. If the process value

overshoots the set point, increase Rate* to 0.50

minute. Increase the set point by 11° to 17°C and

watch the approach to the new set point. If you

increase Rate* too much, the approach to the set

point will be very sluggish. Repeat as necessary

until the system rises to the new set point without

overshoot or sluggishness.

*Note: With the

[Unit]

parameter set at

[``SI]

(Setup Page)

Integral will appear in place of Reset and Derivative will appear

in place of Rate.

**Note: Integral is the reciprocal of reset. For Integral instead of

reset, use the values in parentheses.

For additional information about autotune and PID

control, see related features in this chapter.

TRU-TUNE+™ Adaptive Control

If your Series SD controller was ordered with the

TRU-TUNE+™ option (SD_E - _ _ _ _ - _ _ _ _) the TRU-

TUNE+™ feature can be enabled or disabled in the Setup

Page. The TRU-TUNE+™ feature is enabled as the de-

fault condition. If TRU-TUNE+™ is disabled, the control-

ler will control using fixed PID settings (non adaptive).

The TRU-TUNE+™ adaptive algorithm will optimize

the Series SD controller’s PID values to improve the con-

troller’s ability to control difficult-to-control or dynamic

processes. TRU-TUNE+™ monitors the process variable

and adjusts the control parameters automatically to keep

your process at set point during set point and load chang-

es. When the controller is in the adaptive control mode, it

determines the appropriate output signal and, over time,

adjusts the control parameters to optimize responsive-

ness and stability. The TRU-TUNE+™ feature does not

function for on-off control.