Alarms, Single set point ramping, Process or deviation alarms – Watlow Series SD PID Profiling Controller User Manual

Page 72: Alarm set points

Wa t l o w S e r i e s S D

•

7 0

•

C h a p t e r 1 2 F e a t u r e s

ing is done only at the zero cross of the ac line, which

helps reduce electrical noise (RFI).

Variable time base should be used with solid-state

power controllers, such as a solid-state relay (SSR) or

silicon controlled rectifier (SCR) power controller. Do not

use a variable time base output for controlling electrome-

chanical relays, mercury displacement relays, inductive

loads or heaters with unusual resistance characteristics.

The combination of variable time base output and a

solid-state relay can inexpensively approach the effect of

analog, phase-angle fired control.

You must select the AC Line Frequency, 50 or 60 Hz.

100 percent output

10 ON, 0 OFF

50 percent output

3 ON, 3 OFF

66 percent output

6 ON, 3 OFF

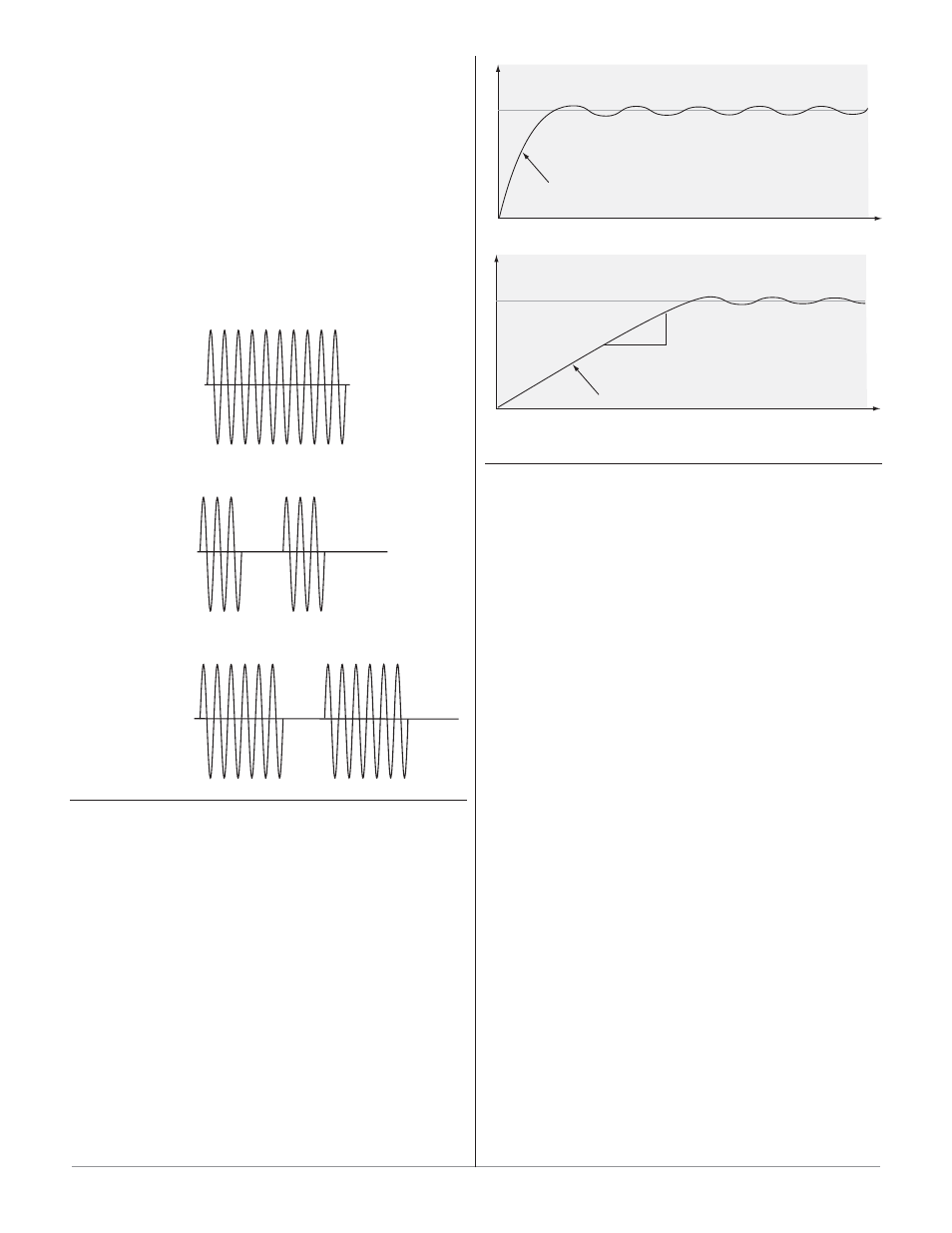

Single Set Point Ramping

(static set point version only SD_C- _ _ _ _- _ _ _ _)

Ramping protects materials and systems that can-

not tolerate rapid temperature changes. The value of the

ramp rate is the maximum degrees per minute or hour

that the system temperature can change.

Select Ramping Mode

[``rP] (Setup Page):

[`OFF] ramping not active.

[`Str] ramp at startup.

[``On] ramp at startup or when the set point changes.

Select whether the rate is in degrees per minute or

degrees per hour with Ramp Scale

[rP;Sc] (Setup Page).

Set the ramping rate with Ramp Rate

[rP;rt] (Setup

Page).

Set Point

Time

Temperature

Temperature reaches Set Point quickly

Set Point

Time

Temperature

Temperature ramps to Set Point at a set rate

degrees

per minute

Alarms

Alarms are activated when the process value or tem-

perature leaves a defined range. A user can configure

how and when an alarm is triggered, what action it takes

and whether it turns off automatically when the alarm

condition is over.

Configure alarm outputs in the Setup Page before set-

ting alarm set points.

Process or Deviation Alarms

A process alarm uses one or two absolute set points to

define an alarm condition.

A deviation alarm uses one or two set points that are

defined relative to the control set point. High and low

alarm set points are calculated by adding and/or sub-

tracting offset values from the control set point. If the

set point changes, the window defined by the alarm set

points automatically changes with it.

Select the alarm type with the Setup Page param-

eters. View or change process or deviation set points with

the Operations parameters.

Alarm Set Points

The alarm high set point defines the process value or

temperature that will trigger a high side alarm. It must

be higher than the alarm low set point and lower than

the high limit of the sensor range.

The alarm low set point defines the temperature that

will trigger a low side alarm. It must be lower than the

alarm high set point and higher than the low limit of the

sensor range.

View or change alarm set points with the Operations

parameters.