IAI America PCON-CFA User Manual

Page 182

5. Flow and Commands of Basic MECHA

TROLINK Communication

176

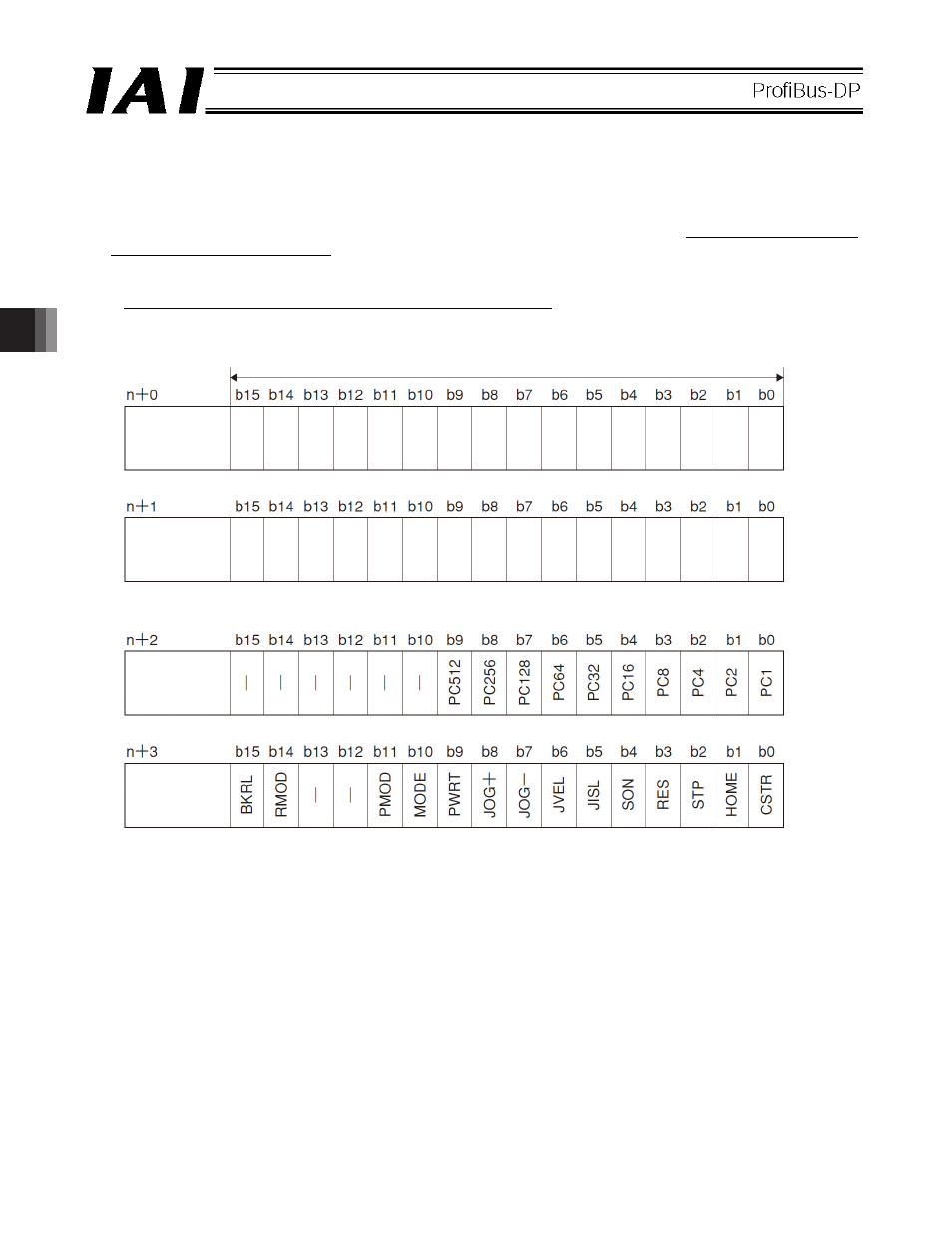

(2) I/O signal assignments for each axis

An I/O signal of each axis consists of 4 words (8 bytes) of I/O addresses.

z Control signals and status signals are bit ON/OFF signals.

z The target position and current position are both a 2-word (32-bit) binary data. Although values from -999999

to +999999 (unit: 0.01 mm) can be handled by the PLC, set position data within the software stroke range (0

up to the effective stroke length) of the applicable actuator.

z The specified position number and completed position number are both a 1-word (16-bit) binary data.

Although values from 0 to 767 can be handled by the PLC, use the PC software or teaching pendant to specify

a position number for which operation conditions are already set.

PLC output

address

(* n indicates the initial output address for each axis.)

1 word = 2 bytes = 16 bits

Target

position

(upper word)

Target

position

(lower word)

Specified

position

number

Control signal

If the target position is a negative value, it is expressed by a 2’s complement.