Maintenance and inspection, 1 inspection items and schedule, 2 visual inspection of the exterior – IAI America RCS2-SD5N User Manual

Page 64

10. Maintenance and Inspection

-58-

10. Maintenance and Inspection

10.1 Inspection Items and Schedule

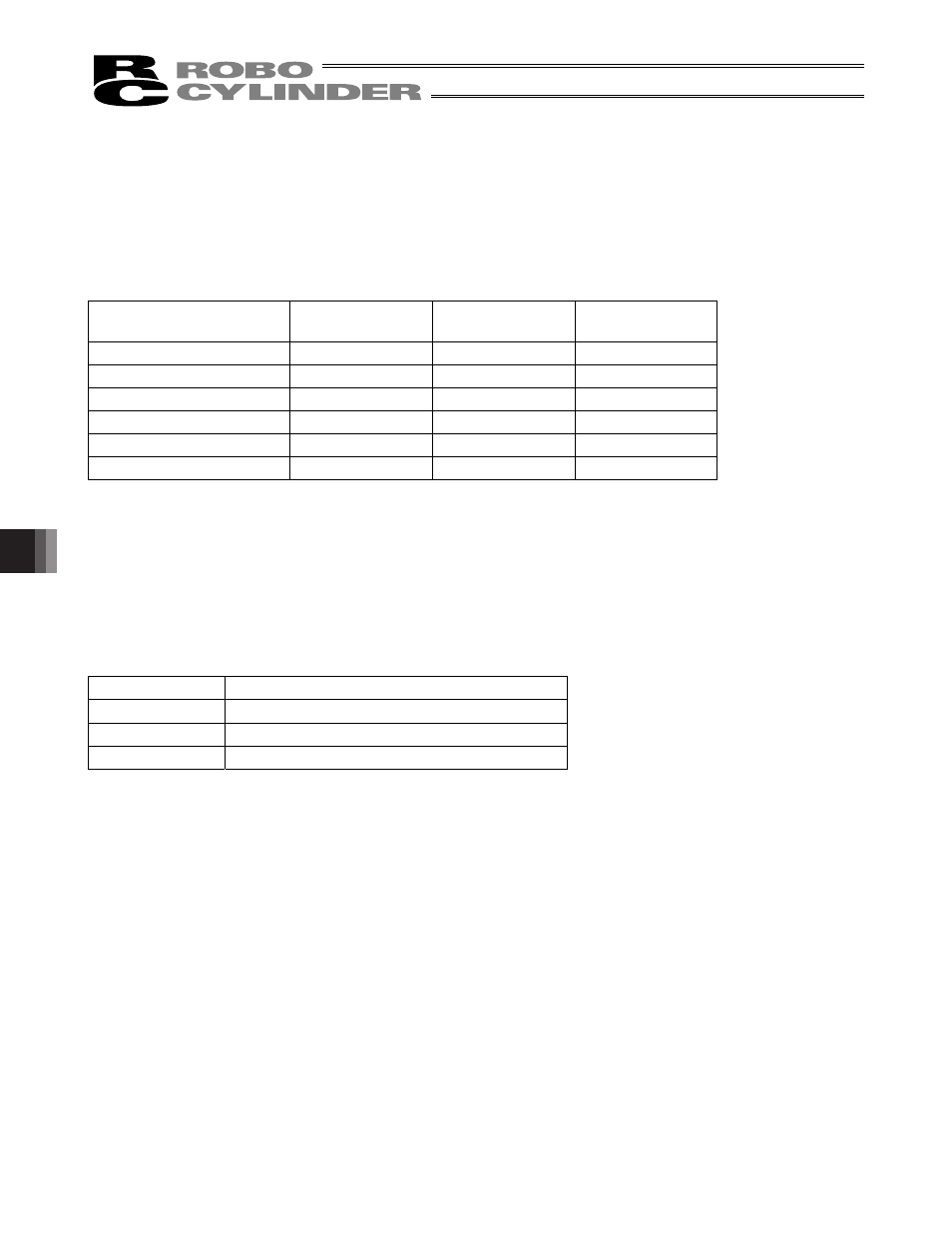

Perform maintenance and inspection at the schedules specified below.

This schedule assumes 8 hours of operation a day.

If the actuator is operated continuously day and night or at a higher utilization rate, shorten the inspection

intervals according to the situation.

Visual inspection

of exterior

Inspection

of interior

Greasing

*1

Startup inspection

{

1 month after startup

{

6 months after startup

{

{

12 months after startup

{

{

{

Every 6 months thereafter

{

Every 12 months

{

{

{

*1 If the actuator is operated back and forth repeatedly over a distance of 30 mm or less, the oil film created by

the grease may be broken. As a rough guide, move the actuator back and forth five times or so over a

distance of 50 mm or more after every 5000 to 10000 cycles. This will restore oil film. (If your ROBO Cylinder

has a stroke of less than 50 mm, move the actuator back and forth over a distance corresponding to the

entire stroke.)

10.2 Visual Inspection of the Exterior

In the visual inspection of exterior, check the following items.

Actuator

Loose actuator mounting bolts, etc.

Cables

Scratches, connection at connectors

Spiral cover

Scratches, dents, foreign attachments

Overall

Abnormal noise, vibration

x

The spiral cover is a consumable part. As a rough guide, expect it to last for 2 million cycles. For the method to

replace the spiral cover, refer to 10.7, “How to Replace the Spiral Cover.”

(Note) The life of the spiral cover varies significantly depending on the use environment. If foreign matter (dust

or highly viscous oil) attaches to the surface of the spiral cover, the cover can no longer

expand/contract and its life will be reduced. So that the spiral cover will last longer, clean the surface of

the cover on a regular basis.