IAI America RCS2-SD5N User Manual

Page 31

6. Installation

-25-

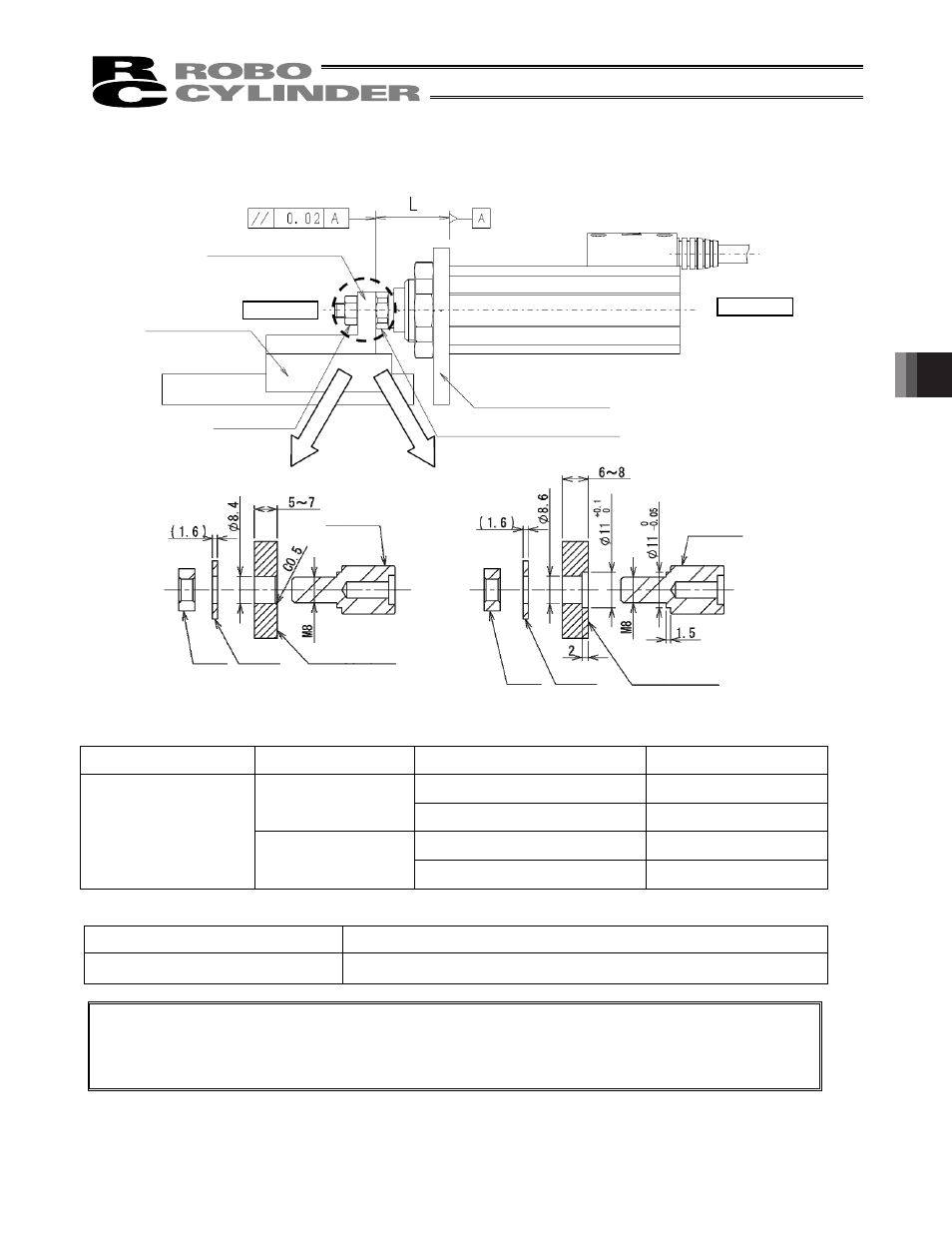

Keep the concentricity between the actuator mounting hole in the actuator mounting hole and end-bracket

mounting hole in the guide-side bracket, to within 0.05 mm. Also keep the parallelism to within 0.02 mm.

Type

Lead

Guide-side bracket

L

Without counterbore

45.2r0.1

2.5

With counterbore

43.7r0.1

Without counterbore

45.5r0.1

RN5N

5.10

With counterbore

44.0r0.1

Tightening torque for end clasp

Type

Tightening torque

RN5N

7 Nxm

Caution: Do not join the actuator detent using a floating joint.

A radial load will be applied due to an eccentricity of the screw shaft, resulting in actuator

malfunction or premature damage.

Guide-side bracket

Detent guide

Flat nut

Flat washer

End bracket

Guide-side bracket

M8 nut

End bracket

Guide-side bracket

Flat washer

M8 nut

RN5 Guide-side bracket(without counterbore)

RN5 Guide-side bracket(with counterbore)

Actuator mounting plate

(prepared by the customer)

(prepared by the customer)

Rear side

Front side

End bracket (13 mm across flats)