3 single guide types, 3 single guide types gs5n – IAI America RCS2-SD5N User Manual

Page 51

6. Installation

-45-

depth 5

depth 5

4-M5, through

de

pt

h

5

8-M5, depth 7.5

(same on opposite side)

(same on opposite side)

depth 5

Home

depth 5

depth 5

4-M5, depth 7.5

4-M5, depth 10

[Load mounting surface]

(same on opposite side)

depth 5

depth 5

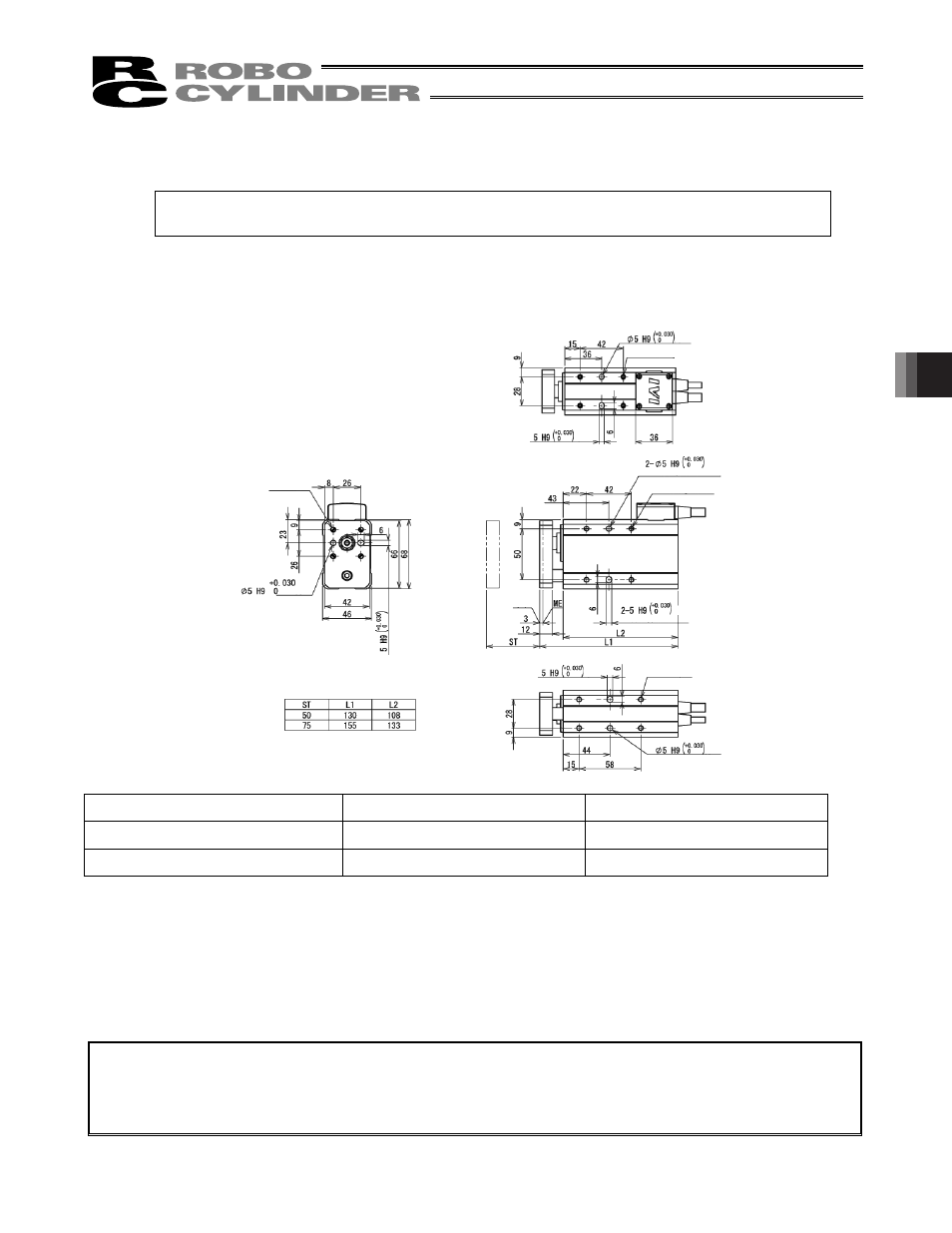

6.3 Single Guide Types

GS5N

The actuator mounting surface should be machined or otherwise processed to a smooth surface

of equivalent preciseness.

x

The effective depth varies depending on the actuator model and mounting surface. Determine an appropriate

length for the screws to be used by referring to the figure below.

x

Circular and long positioning pin holes are provided in each mounting surface. Use these holes if necessary.

The actuator is structured in such a way that it can be affixed on any of its four sides. The load can be

installed only one side.

Tightening torque

Tapped hole diameter

Bolt bearing surface is steel

Bolt bearing surface is aluminum

M5, depth 7.5

545 Nxcm (55.6 kgfxcm)

270 Nxcm (27.5 kgfxcm)

M5, depth 10, 12

727 Nxcm (74.2 kgfxcm)

342 Nxcm (34.9 kgfxcm)

About the tightening screws

x

Use hexagonal socket head bolts for the male base mounting bolts.

x

It is recommended to use high-tension bolts of ISO 10.9 or higher strength.

x

Make sure the effective engagement length between the bolt and female thread is equal to or greater than

either of the following values, whichever is applicable:

Female thread is made of aluminum Æ Twice the nominal diameter (If the depth is no more than twice the

nominal diameter, the length shall not exceed the depth.)

Caution: Some tapped mounting holes are through holes. Never use long screws exceeding the effective

thread length.

Such long screws may damage the internal mechanism or electrical parts.