IAI America RCS2-SD5N User Manual

Page 37

6. Installation

-31-

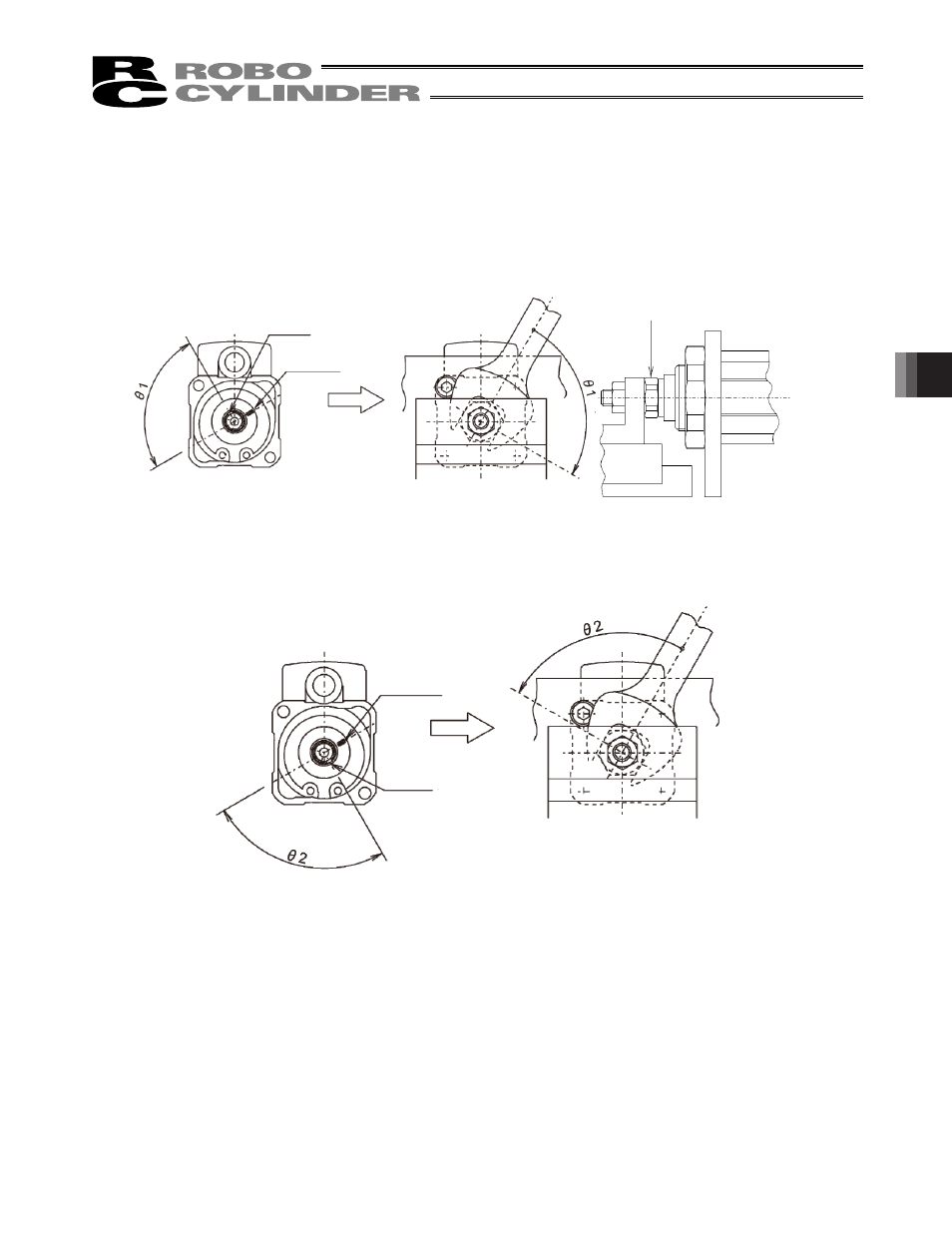

[Procedure 2] Correcting the position of encoder Z-phase

If the cutout groove in the shaft is outside the allowable angle range, make corrections by following the

procedure below:

[1] Use a spanner wrench to hold the width across flats on the clasp at the end to keep it in position, and loosen

the lock nut slightly.

[2] Move the clasp at the end slightly in the rotating direction to correct the position.

x

If the cutout groove in the shaft is deviated in the A (NG) direction:

Move the clasp at the end clockwise roughly by the correction angle T1 (as viewed from the front).

x

If the cutout groove in the shaft is deviated in the B (NG) direction:

Move the clasp at the end clockwise roughly by the correction angle T2 (as viewed from the front).

[3] After the correction, tighten the lock nut with the clasp at the end still held in position.

[Procedure 3] Confirming the Z-phase position again

Finally, repeat [Procedure 1] to confirm the position of Z-phase again.

If the position is inside the allowable angle, Z-phase has been corrected properly.

As viewed from the front

Marking

(orange)

Cutout groove

in shaft

As viewed from the front

Apply a spanner wrench.

Marking

(orange)

Cutout groove

in shaft

Appropriate position of

cutout groove in shaft

Appropriate position of

cutout groove in shaft