IAI America RCS2-SD5N User Manual

Page 48

6. Installation

-42-

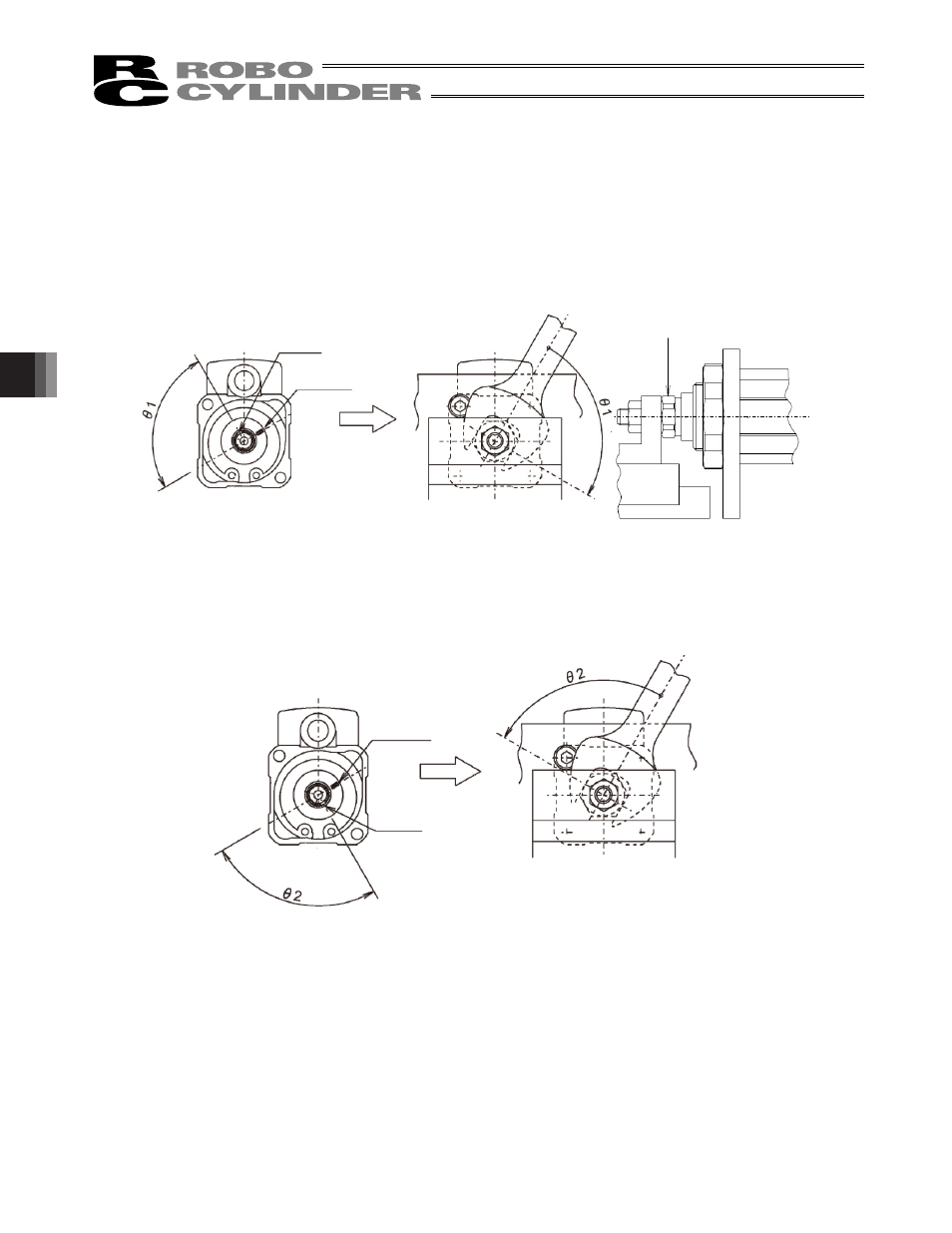

[Procedure 2] Correcting the position of encoder Z-phase

If the cutout groove in the shaft is outside the allowable angle range, make correction by following the procedure

below:

[1] Use a spanner wrench to hold the width across flats on the clasp at the end to keep it in position, and loosen

the lock nut slightly.

[2] Move the clasp at the end slightly in the rotating direction to correct the position.

x

If the cutout groove in the shaft is deviated in the A (NG) direction:

Turn the clasp at the end in clockwise direction by using the amount of displacement T1 as a rough guide

(when viewed from the front).

x

If the cutout groove in the shaft is deviated in the B (NG) direction:

Turn the clasp at the end in clockwise direction by using the amount of displacement T2 as a rough guide

(when viewed from the front).

[3] After the correction, tighten the lock nut with the clasp at the end still held in position.

[Procedure 3] Confirming the Z-phase position again

Finally, repeat [Procedure 1] to confirm the position of Z-phase again.

If there is no longer displacement or error, the correction has been successful.

As viewed from the front

Marking

(orange)

Cutout groove

in shaft

As viewed from the front

Apply a spanner wrench.

Marking

(orange)

Cutout groove

in shaft

Appropriate position of

cutout groove in shaft

Appropriate position of

cutout groove in shaft