Set handing, Pring, Hysical – Controlled Products Systems Group STRONGARMPARK DC 10 User Manual

Page 74: Ever, Ssembly

7-2

D0536 Rev. B

StrongArmPark DC: Programming & Operations Manual

www.hysecurity.com

s

prIng

& p

HYsICal

s

top

l

ever

a

ssemBlY

12

7

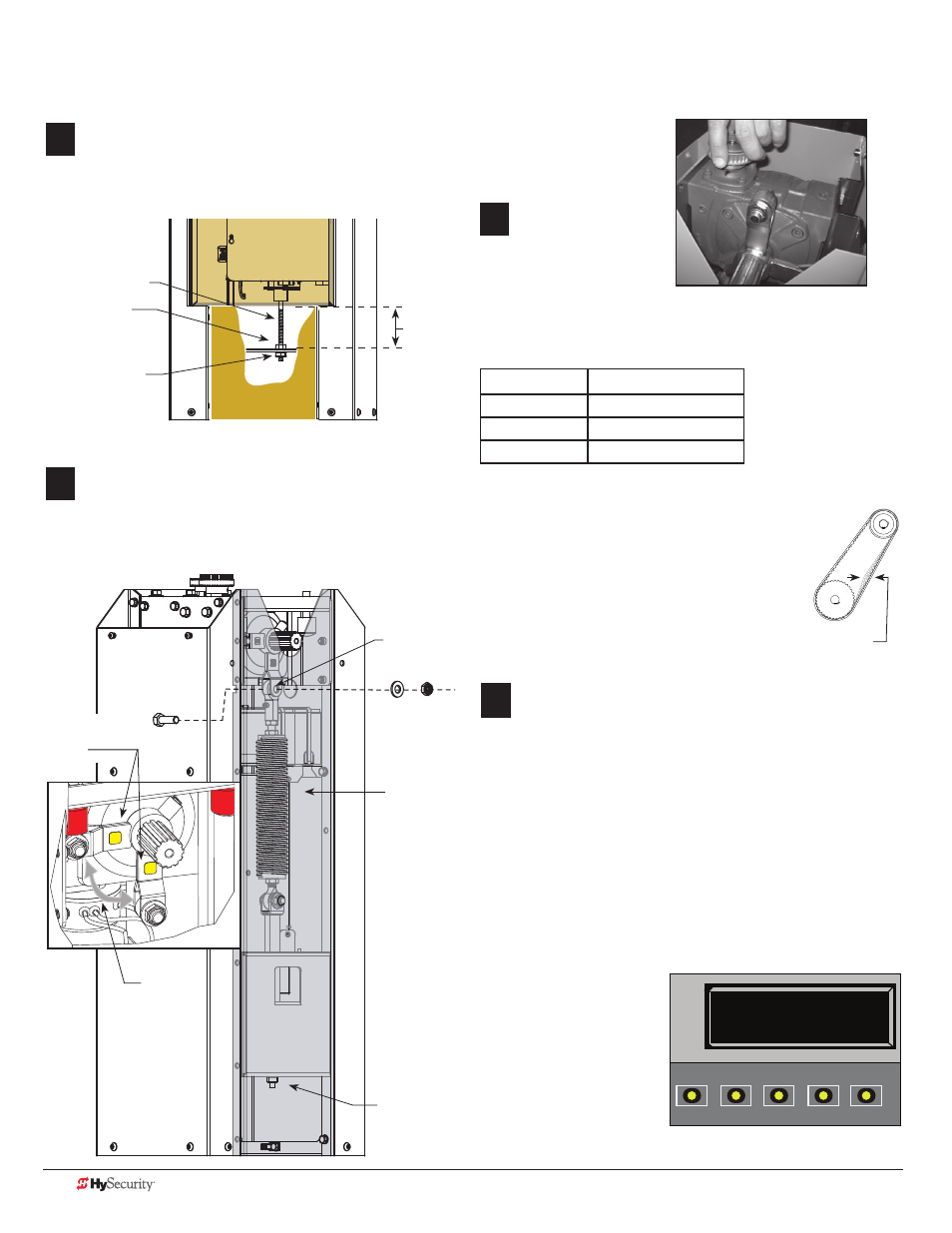

Remove spring tension. Use a crescent wrench (or 12 point

ratchet) to remove the square base nut and washer.

NOTE: You do not need to loosen the nut on the top of the

bracket. It helps keep the spring tension at factory settings.

Square top nut

Square base nut

All thread rod

12

8

Swap physical stop lever hardware. Use a 3/4-inch deep well

socket and box end wrench to remove the fasteners securing

the eyebolt. Then, loosen and remove the fasteners from

the other the physical stop lever and swap positions on the

physical stop levers.

Spring

Eyebolt

Physical stop

levers.

Square base nut

12

9

NOTE: For better access, you

can rotate the gear box to

reposition the physical stop

levers.

12

10

Reverse the steps found

on page 1.

Set Handing

Turn ON the DC power switch and set the handing

using the Smart DC Controller.

• Press MENU twice.

• Press and hold OPEN and RESET, and then release.

• Press NEXT until GATE HANDING appears.

• Press SELECT. SH blinks.

• Press NEXT to set the handing (Left or Right).

• To accept what is being displayed, press SELECT.

• To exit Menu mode, press RESET.

• Turn OFF the DC power switch.

• Install the breakaway bracket by aligning its splines with

the gear box.

• Assemble the arm,

apply power, and

re-learn limits.

• Finish the site

installation.

SH R (RIGHT)

GATE HANDING

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

L

R

Swap

locations

(Remove/

Replace

fasteners

and

eyebolt.)

• Insert the all thread and

re-attach the base nut.

• Tighten the two base nuts to the required

“H” dimension. See chart.

Arm Length Spring Setting (H)

11 - 12 ft (3.6 m) 3.5 inches (89 mm)

12 - 13 ft (4 m)

3 inches (76 mm)

13 - 14 ft (4.3 m) 2.5 inches (63 mm)

StrongArmPark DC 14

NOTE: If the arm length is less than 11 ft (3.3 m), disconnect

the spring from the physical stop lever.

H

• Replace the motor and reconnect the 3 wire leads.

• Replace the drive belt and adjust the tension by

sliding the motor plate and tightening its 4 bolts.

• Replace the physical stop bracket removed in

step 3.

• Replace the drive belt cover.

1/16 to 1/8-inch

(1.6 to 3.2 mm)