Franklin Fueling Systems TS-DTU Data Transfer Unit Dispenser Retrofit Manual User Manual

Page 27

Wayne Ovation - DTU Installation

27

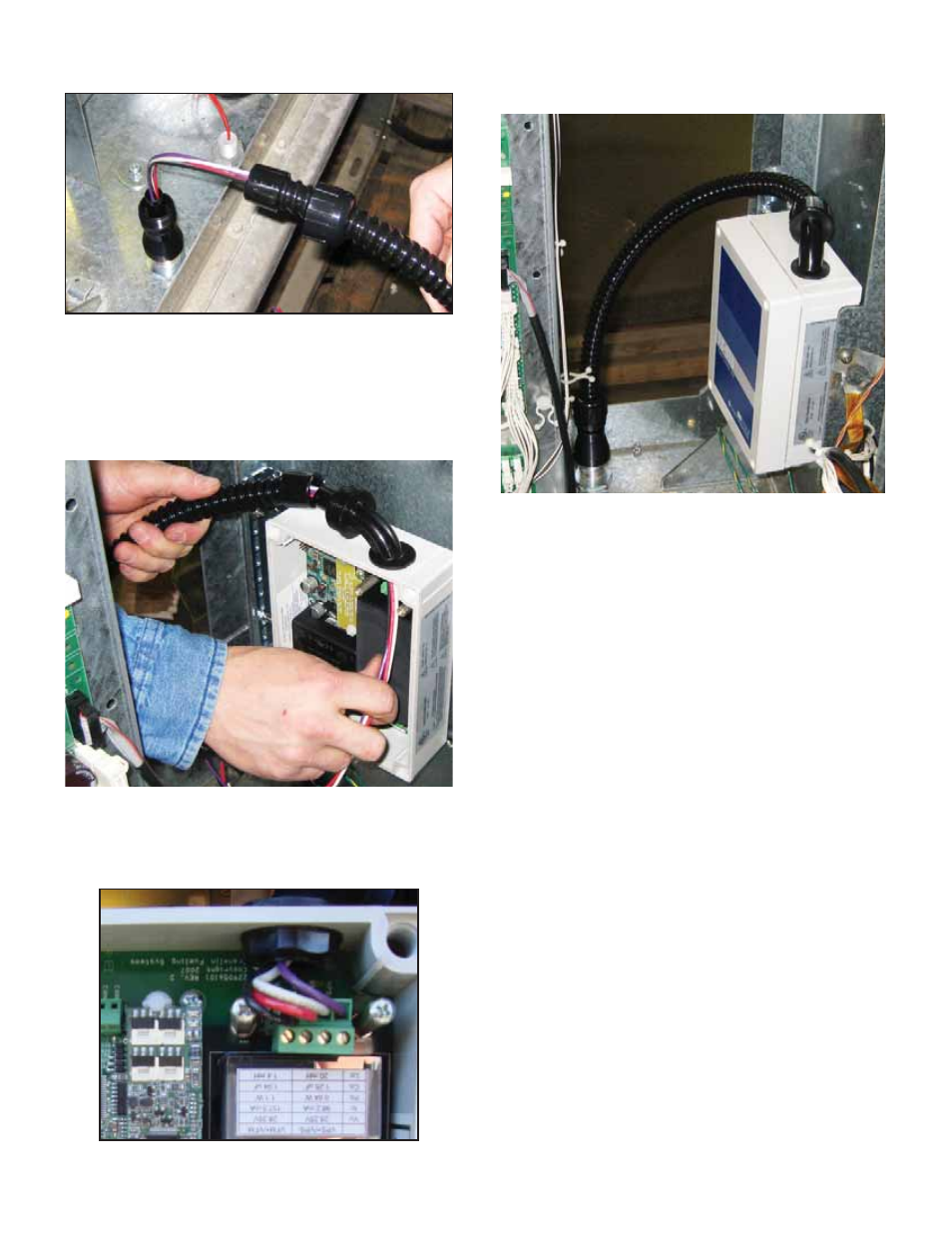

29. Push bushing onto end of fl exible conduit and

reattach to straight fi tting using nut.

Figure 14: Attach Flexible Conduit to Potted Nipple

30. Remove bushing and nut from 90-degree fi tting on

DTU and pull wiring and fl exible conduit through.

31. Pull wires through 90-degree fi tting and pull into

the DTU enclosure.

32. Use nut and attach fl exible conduit to 90-degree

fi tting.

Figure 15: Attach Flexible Conduit to 90-Degree Fitting

33. Cut excess wire inside DTU allowing a length of 2”

for terminal block wiring. Strip insulation 3/8” from

end of wire. Attach wires to DTU terminal block as

follows

Figure 16: Terminal Block Wiring

34. Reinstall barrier cover using screws removed in

step 24.

35. Replace DTU cover.

Figure 17: Attach Cover to DTU

36. Find cable assembly extending from TS-VFM

vapor meter in dispenser hydraulics enclosure.

37. Locate wiring from previously installed potted

nipple assembly inside hydraulics enclosure.

38. Find two-wire splice connector kits. Inside hydraulics

enclosure connect black wire from potted nipple

assembly to black wire from TS-VFM fl ow meter by

placing each lead into an opening in the wire splice

connector and push fi tting closed to lock.

39. Find cable extending from TS-VPS inside

hydraulics enclosure. Cut yellow and blue leads

from end of cable.

40. Find purple and white wires from potted nipple

assembly in hydraulics enclosure. Strip wiring

insulation at end 3/8”.

41. Using wire nuts provided with kit, attach purple

wire from potted nipple assembly to black wire of

TS-VPS and attach white wire from potted nipple

assembly to white wire of the TS-VPS.

42. Replace lower hydraulics door using two screws

on door.

43. Close dispenser doors on each side of the unit and

fi rmly attach with two screws located in each door.