Table 24, Motor feedback, Connector pinout – Parker Hannifin 88-021610-01G User Manual

Page 63

Parker Hannifin

Chapter 3 Electrical Installation 63

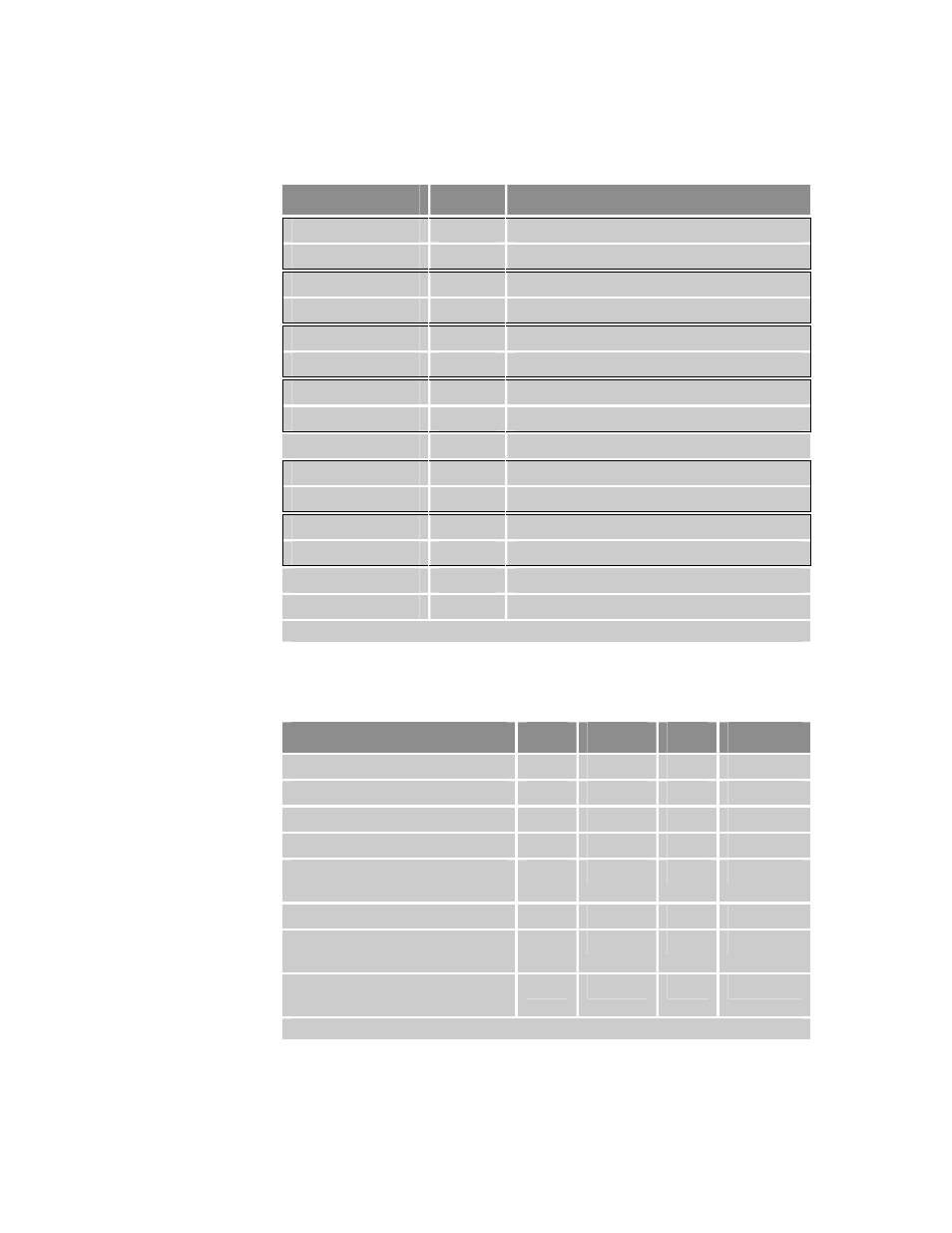

Pinout—

MOTOR FEEDBACK

Connector

Note:

A box surrounding pins indicates a requirement for twisted pair wiring.

Signal

Pin

Description

ENC Z+ / Data+

1

Encoder Z Channel in

ENC Z– / Data–

2

Encoder Z Channel in

DGND

3

Encoder power return

+5 VDC

4

+5 VDC Encoder power

+5 VDC

5

+5 VDC Hall power

DGND

6

Hall power return

ENC A– / SIN–

7

Encoder A Channel in

ENC A+ / SIN+

8

Encoder A Channel in

Hall 1 / SCLK+ *

9

Hall 1 input

Thermal+

10

Motor thermal switch/thermistor

Thermal–

15

Motor thermal switch/thermistor

ENC B / COS–

11

Encoder B Channel in

ENC B+ / COS+

12

Encoder B Channel in

Hall 2 / SCLK– *

13

Hall 2 input

Hall 3

14

Hall 3 input

*

When using the SinCos protocol, pins 9 and 13 require twisted pair wiring.

Table 24

MOTOR FEEDBACK

Connector Pinout

Inputs—Encoder

Description

Min

Typical

Max

Units

Common Mode Range

-7

+7

V

Current—Encoder

250

mA

Current—Hall

250

mA

Differential Threshold Voltage

-200

+200

mV

Differential Termination

Impedance

120

ohms

Thermal Switch Current

2

mA

Thermal Switch Voltage

Maximum (supplied)

15

V

Input Frequency

(pre-quadrature)

5

MHz

Note:

All parameters are at the connector pin.

Table 25 Inputs—Encoder Inputs Electrical/Timing Characteristics