Parker Hannifin Dynaserv G2 User Manual

Page 142

11-7

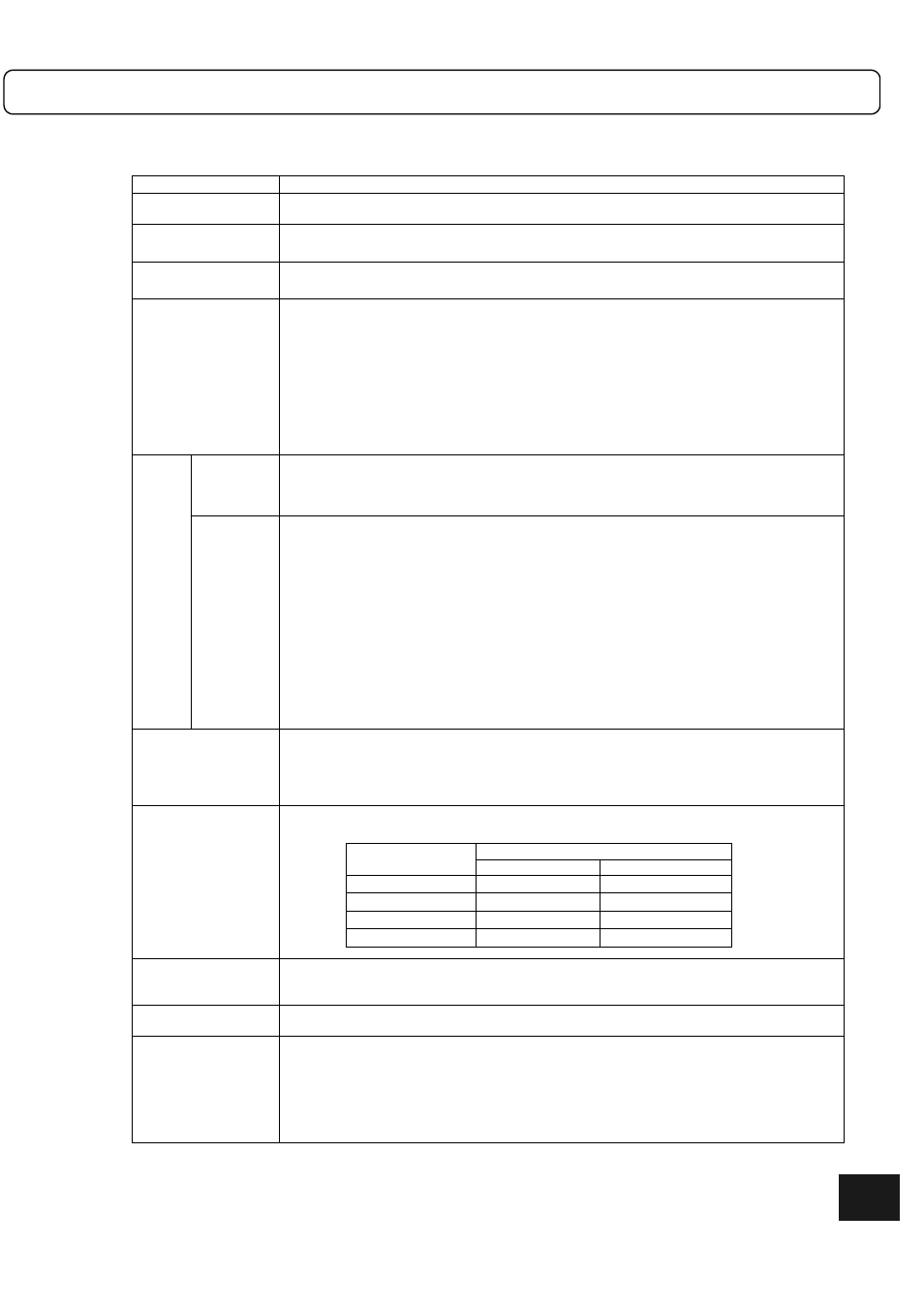

(6) Driver Function Specifications

Item

Specifications

Higher interface

RS232C interface (single channel communication, multi-channel communication)

Controller interface (pulse train position command)

Mechanical input

signal

Homing signal, (+) direction hardware over-travel signal, (-) direction hardware over-travel

signal, emergency stop input signal

Mechanical input

signal

Brake signal (can be switched between clamp and dynamic brake applications with a

parameter)

Encoder resolution

(position command

resolution when

shipped)

Rotating type

DM1000A series ; 4096000 pls/rev (1024000 pls/rev)

DM1000B series ; 2621000 pls/rev (655360 pls/rev)

DM1004B/C ; 2621000 pls/rev (655360 pls/rev)

DR1000A series ; 1638400 pls/rev (819200 pls/rev)

DR1000B series ; 1015808 pls/rev (507904 pls/rev)

DM1000E series ; 1228800 pls/rev (614400 pls/rev)

DR5000B series ; 557056 plc/rev (278528 pls/rev)

DR5000E series ; 638976 pls/rev (319488 pls/rev) stiffness series: 0.5

µm,

Linear

LM1/2 ; 0.25

µm (0.25 µm)

LM3/5 ; 0.5

µm (1.0 µm)

Method

I-PD position control (position: integral proportional control, velocity: proportional control)

Various feed forward functions (position, velocity, acceleration)

Various standard filters (velocity command filter, velocity feedback filter, first order delay filter)

Optional filter (notch filter 2 channels)

Control

part

Adjustment

Position control bandwidth:1 Hz to 32Hz, velocity control loop width: 5Hz to 200Hz

Position integral limiter setting

Various feed forward percentages (position, velocity, acceleration)

Various standard filter settings (velocity command filter bandwidth, velocity feedback filter

enable/disable, bandwidth, first order delay filter setting)

Optional filter setting (notch filter bandwidth)

*1) Calculates proportional gain and acceleration feed forward gain of the velocity control part

automatically based on measurement by the auto-tuning operation or manual setting of

the load inertia/weight with respect to the settings of velocity control bandwidth and

acceleration feed forward percentage.

*2) Calculates position control bandwidth, velocity control loop bandwidth, and position

integral limiting value automatically during execution of the auto-tuning operation or by

manual setting of the servo stiffness

Acceleration/decelerat

ion control

Trapezoidal move: Acceleration curve and deceleration curve can be selected individually.

Acceleration time or deceleration time can be selected individually (with respect to the

maximum velocity).

*3) Real time override possible, interlock possible

Operation function

Follows the position command from the controller interface when none of the operations listed

below is being performed.

Protection functions

Encoder/resolver error, power module error (over-voltage and over current), main power

supply error, overload, maximum velocity, excessive position deviation, hardware over-travel,

software over-travel (only for linear coordinate)

Others

Support software PC utility running under Windows (optional)

Possible to connect the operation display pendant (optional)

Monitor

Analogue signal monitor (velocity, general, torque/thrust command)

For general monitoring, what is shown by the monitor can be selected by setting (position error,

test operation response, position command value, current position value, position command

differential value)

Digital signal monitor (settling signal)

Monitoring internal information by higher interface

Error and alarm display on a 7-segment LED

Pulse train

Operation

Controller interface

RS232C interface

Homing operation

○

○

Test operation

○

○

Auto-tuning

○

○

Jog move

Ч

○

11