Parker Hannifin R-22 User Manual

Hiller, Ontroller, Installation and servicing instructions

The Chiller Controller has the most features of any Sporlan controller.

It will control one or two Sporlan Electric Expansion Valves, and con-

trols superheat by means of pressure-temperature control. The controller

controls each valve independently, and the valves may be different sizes,

i.e. one SEI-2 and one SEH-175. Pressure-temperature superheat control

for one of four common refrigerants may be selected. Controllers can

be ordered configured for R-22, R-134a, R-404A, R-407C and R-507.

The refrigerant type can be changed in the field by use of the optional

“Panel Display.” Onboard readouts show actual superheat, superheat set

point, and valve position. Two push buttons are provided on the board,

to change the superheat set point, as well as open, close, or position the

valve. Proportional and Integral set points are also included to change

responsiveness of the valve.

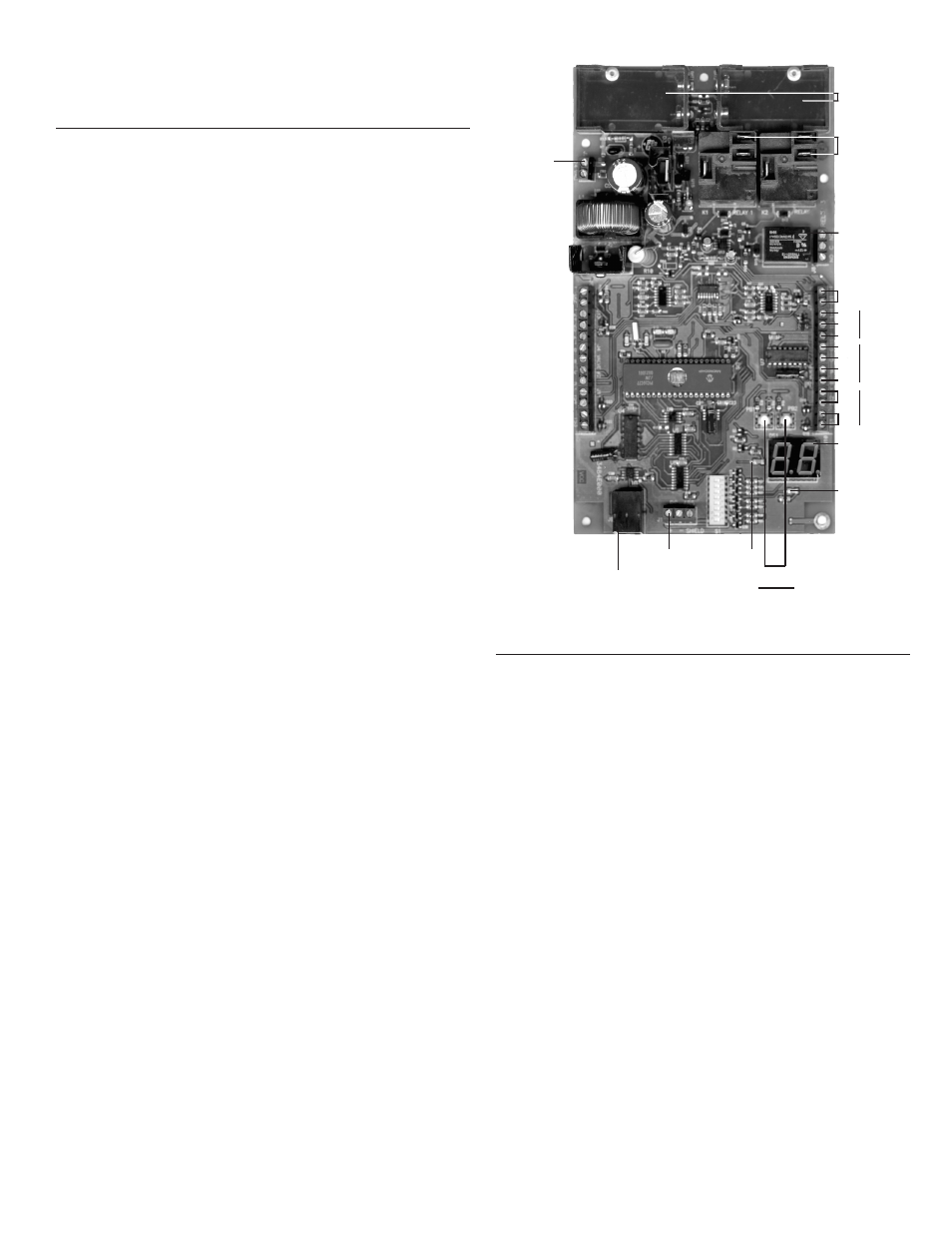

As illustrated in Figure 1, the controller is provided with hardware and

input/output connections for a number of user specified purposes. See

below:

•

One or two valve control

•

Two pressure inputs (transducer supplied by Sporlan)

•

Two digital inputs (from external switches or relays)

•

Four temperature inputs (Sporlan supplied surface or air sensors)

•

Optional battery backup for onboard time clock and fail-safe

valve closure

•

Two digit LED readout

•

One green LED indicator

•

One red LED indicator

•

Two push buttons for set point, alarm cancellation, etc.

•

One 8-position dip switch for addressing, mode selection, etc.

•

Two 20 amp, 240 VAC NC/NO relays

•

One 5 amp 240 VAC NC/NO relay

•

RS 485 port

•

Panel Display jack

Please note that although relays, etc. appear on the Chiller Board,

standard software does not support those devices. Custom (proprie-

tary) software must be written for anything other than superheat con-

trol. Please contact Sporlan Division of Parker for more information.

INSTALLATION

When handling the boards, electrostatic protection procedures should

be followed. The installer should be grounded through a ground

strap. If ground straps or other ESD protection is not available,

ONLY

handle the board by its edges or by the battery holders. DO

NOT TOUCH ANY COMPONENTS ON THE BOARD EXCEPT

THE BATTERY HOLDER AND RELAYS.

1.

The board should be mounted in a dry, protected environment using

the predrilled mounting holes in each corner. Make sure none of the

printed circuit paths or components are touching the metal panel or

any thing else conductive.

2.

If only one valve is used, connections are to be made to terminal

block closest to display readout and push buttons PB1 and PB2.

3.

Controllers are configured for pressure temperature superheat control.

4.

Connect temperature sensor to TS2. The sensor is not polarized. For

suction lines 7/8” or less, the sensor should be mounted to the cop-

per suction line after the evaporator, using the furnished clamps. For

larger lines or steel piping, a “well sensor,” available from Sporlan,

should be installed.

5.

The pressure transducer should be mounted on the top of the suction

line near the temperature sensor location. Transducer connections to

the board are as follows:

•

The power wire is red and is connected to the 1+ terminal.

•

The signal wire is green and is connected to the 1S terminal.

•

The ground wire is black and is connected the 1- terminal.

6.

The valve leads are connected to the terminals labeled Valve 1.

•

The black lead is connected to terminal labeled B of Valve 1.

•

The white lead is connected to terminal labeled W of Valve 1.

•

The green lead is connected to terminal labeled G of Valve 1.

•

The red lead is connected to terminal labeled R of Valve 1.

7.

DI1 is a digital input used as a pumpdown terminal. A short or

closed contact from an external relay will close the valve for pump-

down. When the relay opens or the short is removed, the valve will

return to normal operation.

8.

If two valves are used the second valve and its temperature sensor,

pressure transducer, and pumpdown are connected as above. Caution

should be used on two valve systems to make sure that the sensors are

connected to the terminal strip used for the valve they are controlling.

•

The temperature sensor for Valve 2 is connected to TS4 as

described above.

•

The pressure transducer for Valve 2 is connected to 2+, 2S, 2-

as described above.

•

The valve is connected to terminals labeled Valve 2 as described

above.

•

The pumpdown terminal for Valve 2 is labeled DI2. It is con-

nected as described above.

•

Power is connected to the terminal marked 24VAC. Power

requirements are 24 volts AC at 40 VA. For protection from

electrical transients, connect one MOV varistor between one

leg of the input voltage of the 24 VAC transformer and earth

ground. Connect a second MOV varistor between the other leg of

the input voltage of the 24 VAC transformer to earth ground. A

recommended part number for a MOV is Harris Semiconductor

DI Pumpdown

Terminals

Two 20 ampere

240 VAC

NC/NO relays

One 5 ampere

240 VAC

NC/NO relay

Holders for

Optional Fail

Safe Batteries

1-

1S

1+

Pressure

Transducer

Terminals

Valve 1

Cable

Terminals

TS2 Temperature

Sensor

Terminals

TS1

Two Digit

LED Display

Green

Status LED

Two Push

Buttons

PB1

PB2

Red

Status

LED

RS 485 Post

Panel

Display

Jack

R

G

W

B

24 Volt AC

50/60 Hz.

40 VA Input

C

hiller

C

ontroller

Installation and Servicing Instructions

Figure 1

Terminals for Valve 1 shown.

Terminals for Valve 2 similar.