Honeywell MS-9200UDLSE User Manual

Page 179

Operating Instructions

MS-9200UDLS PN 52750:E1 01/27/09

179

Drift Compensation

Drift compensation uses software algorithms that identify and compensate for long-

term changes in the data readings from each addressable smoke detector. These long-

term changes in detector data readings are typically caused by dirt and dust

accumulation inside the smoke chamber. Drift compensation performs the following

functions:

•

Samples photoelectric smoke detectors every 6 seconds and ionization smoke

detectors every 3 seconds

•

Allows a smoke detector to retain its original ability to detect actual smoke and

resist false alarms, even as dirt and dust accumulate

•

Reduces maintenance requirements by allowing the control panel to

automatically perform the periodic sensitivity measurements required by NFPA

Standard 72

The FACP software also provides filters to remove transient noise signals, usually

caused by electrical interference.

Maintenance Alert

The software determines when the drift compensation for a detector reaches an

unacceptable level that can compromise detector performance. When a detector

reaches an unacceptable level, the control panel indicates a maintenance alert. Table

4.1 summarizes the three levels of maintenance alert:

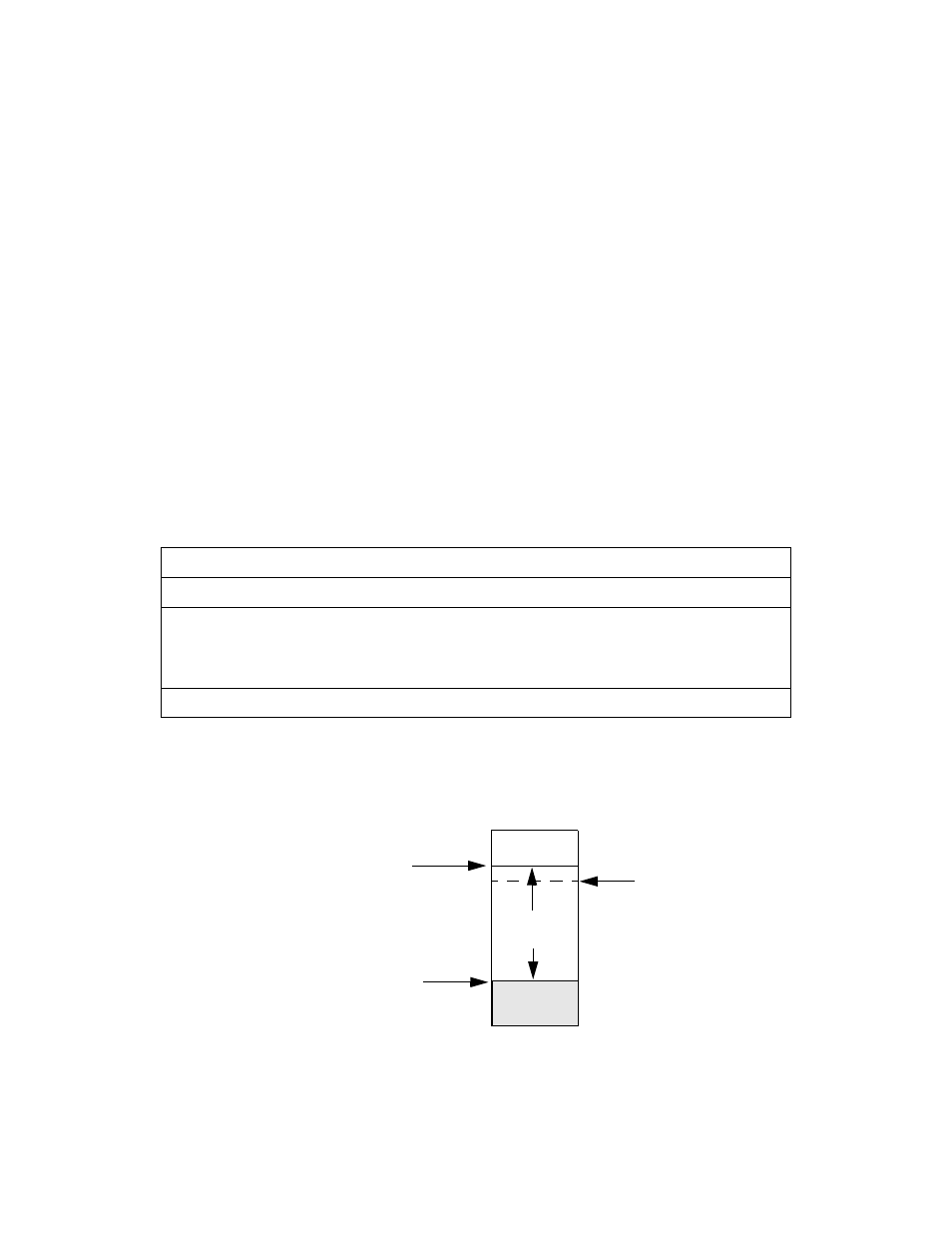

Figure 4.1 illustrates a graphic representation of the maintenance levels:

Maintenance Level

FACP Status Displays

Indicates

Low Chamber Value

INVREP

A hardware problem in the detector

Maintenance Alert

DIRTY1

Dust accumulation that is near but below the

allowed limit. DIRTY 1 indicates the need for

maintenance before the performance of the detector

is compromised

Maintenance Urgent

DIRTY2

Dust accumulation above the allowed limit.

Table 4.1 Maintenance Alert Levels

Figure 4.1 Diagram of Maintenance Levels

DIRTY

Acceptable

Range

Maintenance

Urgent

Maintenance

Alert

Low Chamber

Reading

LOW

VALUE