Xfcappa.pdf – Emerson Process Management ControlWave XFC User Manual

Page 95

ControlWave XFC

Special Instructions for Class I, Division 2 Hazardous Locations

10/03/06

Appendix A, Document CI-ControlWave XFC

Page 1 of 2

1. Bristol, Inc.’s ControlWave XFC (Model 3820-EX) Gas Flow Computer is listed by Underwriters

Laboratories (UL) as nonincendive and is suitable for use in Class I, Division 2, Groups A, B, C and D

hazardous locations or nonhazardous locations only. Read this document carefully before installing a

nonincendive ControlWave XFC (Model 3820-EX) Gas Flow Computer. Refer to the ControlWave XFC

(Model 3820-EX) Gas Flow Computer User's Manual for general information. In the event of a conflict

between the ControlWave XFC (Model 3820-EX) Gas Flow Computer User's Manual and this document,

always follow the instructions in this document.

2. The ControlWave XFC (Model 3820-EX) Gas Flow Computer includes both nonincendive and unrated

field circuits. Unless a circuit is specifically identified in this document as nonincendive, the circuit is

unrated. Unrated circuits must be wired using Div. 2 wiring methods as specified in article 501-4(b) of the

National Electrical Code (NEC), NFPA 70 for installations in the United States, or as specified in Section

18-152 of the Canadian Electrical Code for installation in Canada.

3. All communications ports terminate on a Terminal Block (J2) on the Terminal Plate within the enclosure.

Wiring to this connector (J2) is unrated. No connections may be made to communication ports unless the

user ensures that the area is known to be nonhazardous. Connections to the “Local Port” is temporary,

and must be short in duration to ensure that flammable concentrations do not accumulate while it is in

use.

4. WARNING: EXPLOSION HAZARD - Do Not disconnect power connections within the

ControlWave XFC Enclosure (J6) unless the area is known to be nonhazardous.

5. WARNING: EXPLOSION HAZARD - Substitution of major components may impair suitability

for use in Class I, Division 2 environments.

6. WARNING: EXPLOSION HAZARD - The area must be known to be nonhazardous before

servicing/replacing the unit and before installing or removing I/O wiring.

7. WARNING: EXPLOSION HAZARD - Do Not disconnect equipment unless power has been

disconnected and the area is known to be nonhazardous.

8. A bendable RTD may be supplied with the ControlWave XFC. Connection to the RTD is approved as a

nonincendive circuit, so that Division 2 wiring methods are not required.

9. Signal connectors available for customer wiring are listed in Table A1. I/O Connections are unrated and

must be wired using Div. 2 wiring methods.

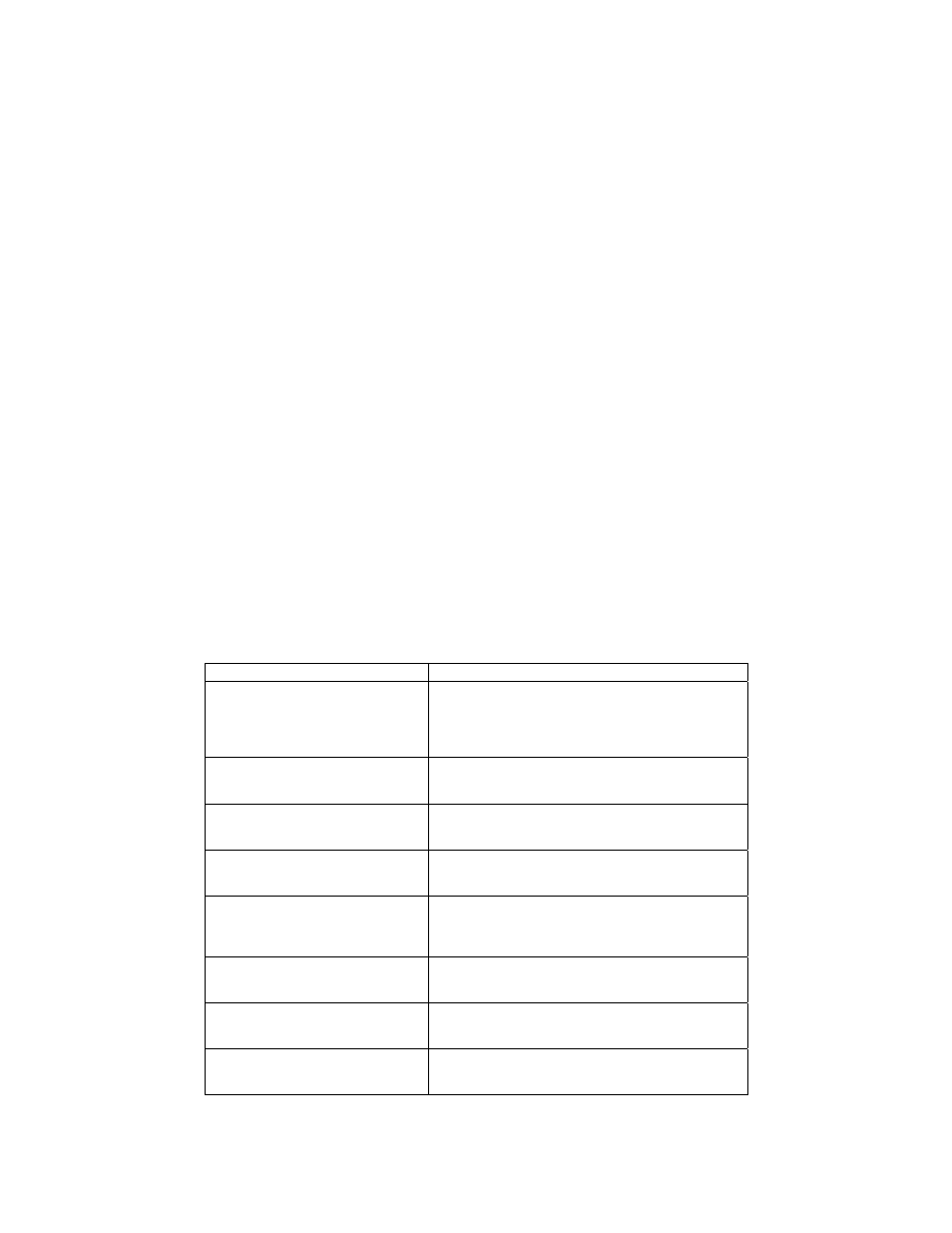

Table A1 -Terminal Plate Connector Customer Wiring Connectors

Connector Wiring

Notes

J2: Pins 1 through 4

RS-485 Comm. Port & Power

connections for Model 3808

Transmitter

RS-485 Comm. Port Connectors: For external

Network Comm. Refer to Model Spec. and ¶ 3

of this document. Use Div. 2 wiring methods *

J2: Pins 5 - 7

RS-232 Local Comm. Port

RS-232 Comm. Port Connectors: For

temporary external Network Comm. Refer to

Model Spec. and ¶ 3 of this document *

J2: Pins 8 - 14

RS-232 Network Comm. Port

RS-232 Comm. Port: For external Network

Comm. Refer to Model Spec. and ¶ 3 of this

document. Use Div. 2 wiring methods *

J3: Pins 1 through 3

RTD Interface

Field Wired: Refer to 8 of this document

J4: Pins 1 through 11

AI/O Interface & Field Power

Analog Input/Output Field Wiring & Unit

supplied (15Vdc) Field Power: Field I/O wiring

connector is unrated, use Div. 2 wiring

methods. *

J5: Pins 1 through 9

DI/O Interface

Discrete Input/Output Field Wiring: Field I/O

wiring connector is unrated, use Div. 2 wiring

methods. *

J5: Pins 9 through 12

HSC Interface

High Speed Counter Input Field Wiring: Field

I/O wiring connector is unrated, use Div. 2

wiring methods. *

J6: Pins 1 and 2

Input Power

Power Interface: Power connector is unrated,

Div. 2 wiring methods. *