Emerson Process Management ControlWave XFC User Manual

Page 17

CI-ControlWave XFC

Introduction / 1-3

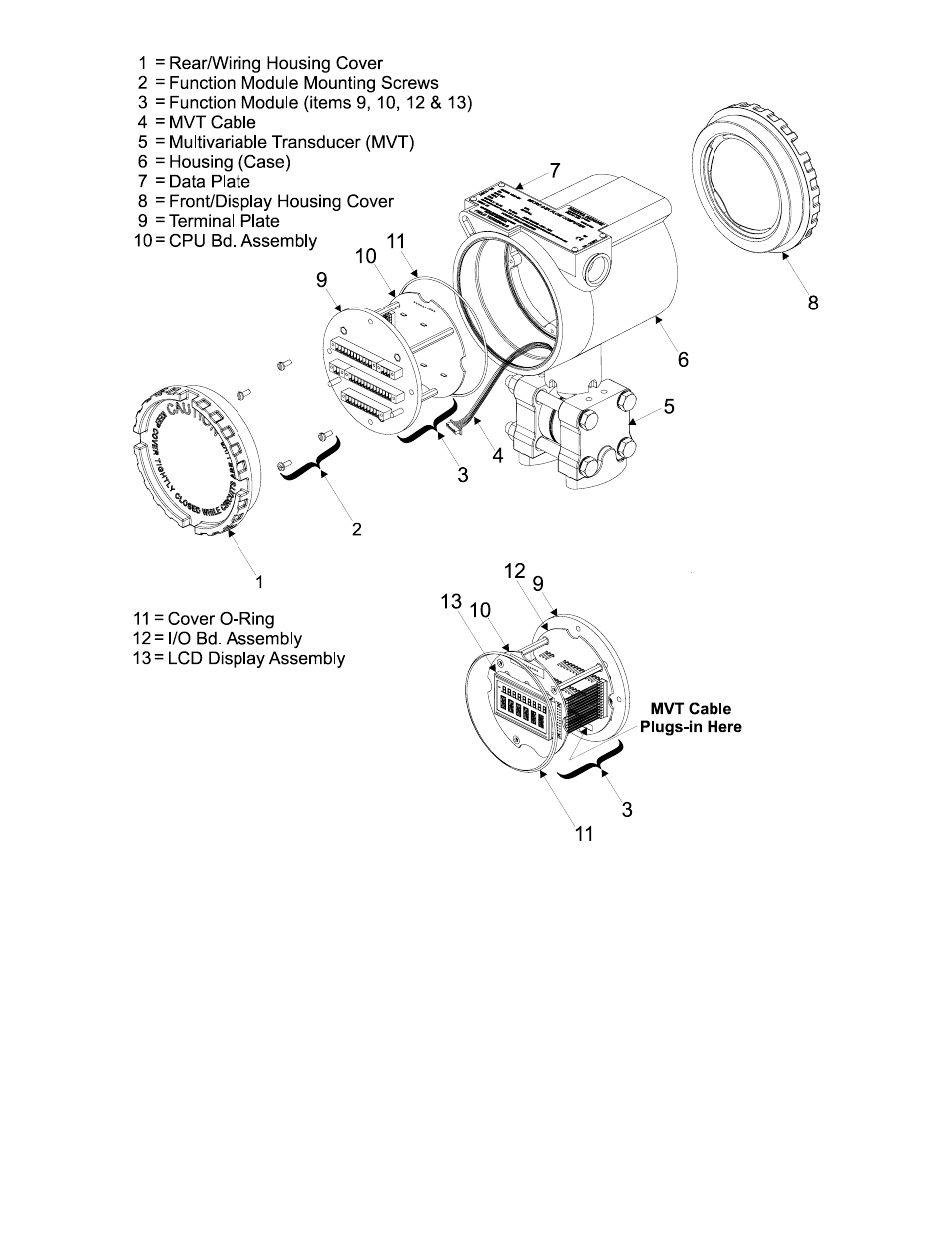

Figure 1-2 - ControlWave XFC (Isometric Views)

Component Identification Diagram (Shown with MVT)

The I/O Board contains I/O field interface circuitry and non-isolated power circuitry. Non-

isolated power is generated and regulated by the I/O Board that provides +3.6Vdc for all

logic and bulk power for I/O field circuits from a bulk source of +6Vdc to +30Vdc.

Additionally, the I/O Board provides 3.3Vdc (logic power) to the CPU Board. +1.8Vdc, used

by the ARM microprocessor, is generated on the CPU Board (derived from the 3.3Vdc).

1.2 ControlWave PROGRAMMING ENVIRONMENT

ControlWave programming environment uses industry-standard tools and protocols to

provide a flexible, adaptable approach for various process control applications in the gas,

water treatment, wastewater treatment, and industrial automation business.