Emerson Process Management ControlWave XFC User Manual

Page 50

2-8 / Installation & Operation

CI-ControlWave XFC

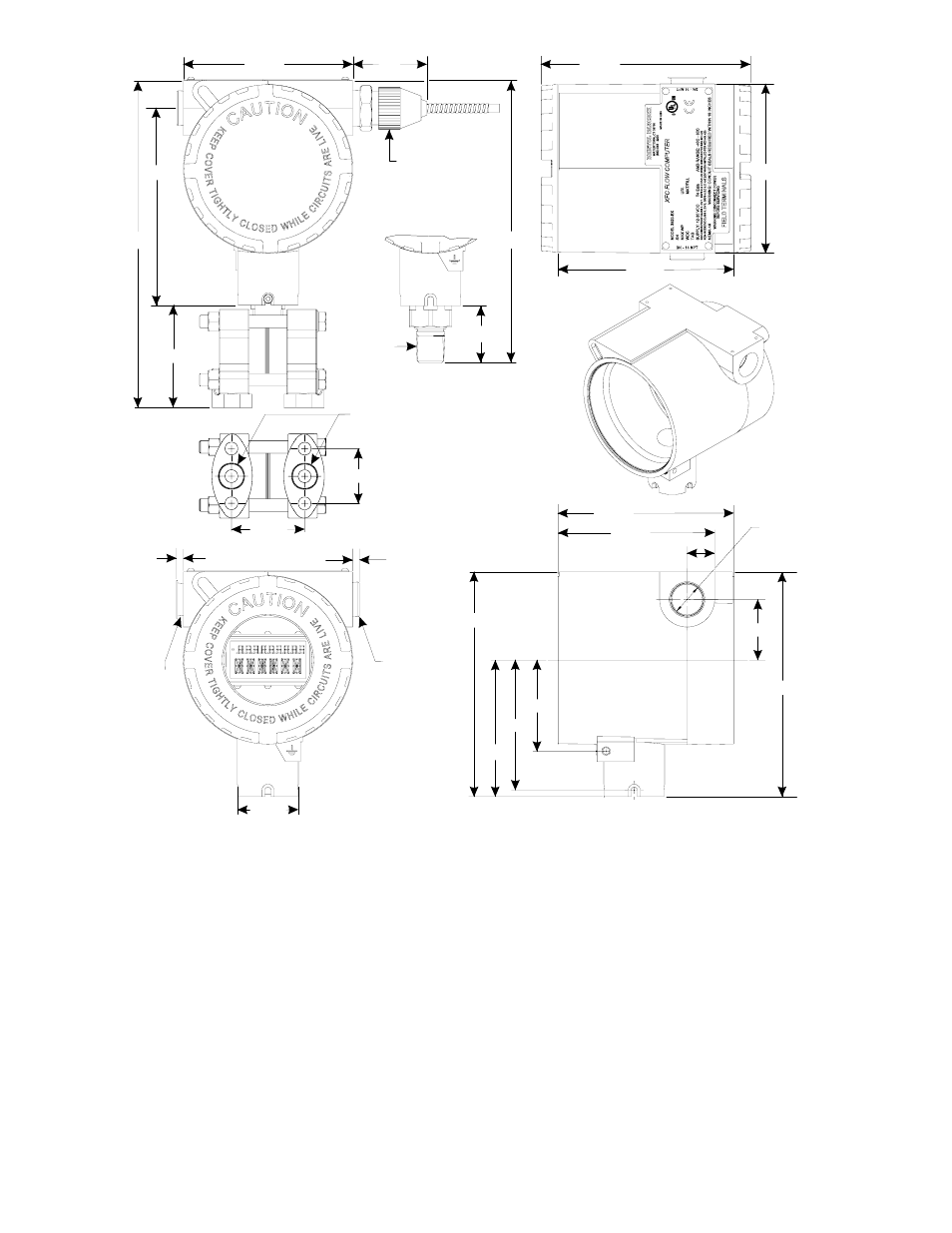

4.938

5.188

LI

STE

D

85K

L

R

5.188

4.630

.75 - 14 NPT

.813

1.788

6.156

2.685

6.156

4.032

3.842

.200

.200

DP

GP

6.190

.75 - 14 NPT

Threaded

Conduit

Plug

.50 - 14 NPT

Male Fitting

Customer Installed

Weather Proof

RTD Bushing

Class I, Div. 2 ONLY

.25 - 18 NPT

Pipe Fittings

Plastic

Conduit

Plug

1.750

3.020

1.720

5.000

9.176

5.820

7.876

2.125

1.625

2.0

Figure 2-3 - ControlWave XFC Dimensions Drawing

- The Multivariable Transducer (MVT) is bolted to a process manifold which in-turn is

connected to the main (meter run) directly or via two pipes (see Figures 2-4 through 2-

6).

- The unit must be positioned so that the front of the assembly is visible and the unit is

accessible for service, i.e., replacement of the Lithium Battery, or installation/removal

of any field wiring, etc.

-

Make certain that the LCD Display is accessible and visible to the on-site operator.

-

Power wiring should not be connected to its source until the unit has been mounted

and grounded at a designated work site.

-

I/O wiring, external power wiring, RTD cabling, local comm. port, and network (RS-

232 and RS-485) Communication Port cabling enter the top of the unit though 3/4 - 14

NPT conduit fittings. I/O wiring may be routed through the right side of the unit

(when facing the front). This requires that the hole plug be removed and replaced with

a 3/4”- 14 NPT Conduit Fitting. If a bendable RTD is used, it will be provided with a