7 combustion calibration, Am series boilers and water heaters – AERCO AM Series Boiler User Manual User Manual

Page 95

AM Series Boilers and Water Heaters

CHAPTER 4 – UNIT START-UP

OMM-0100_0B

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 95 of 156

GF-146

Ph.: 800-526-0288

PRI - 07/14/14

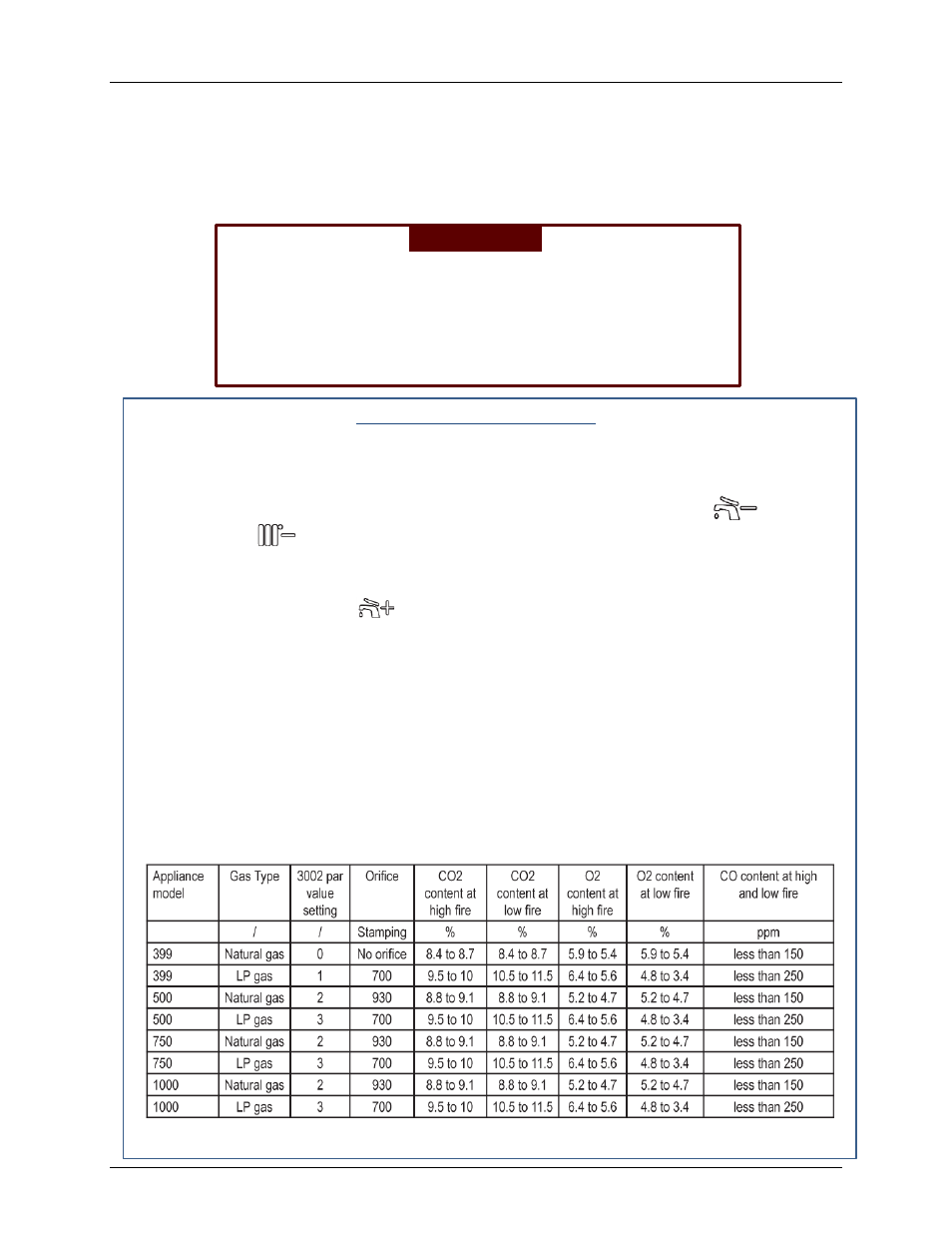

4.7 Combustion Calibration

Table 4-1 lists the correct CO

2

and O

2

ranges for a unit running at normal operating conditions

at an altitude below 4500 feet (1371 meters). CO

2

values outside of the ranges given in Table 4-

1 may lead to malfunctioning of the unit and cause it to prematurely fail. To check the CO

2

values, carry out a combustion analysis as described below:

WARNING!

During this procedure, also compare CO (carbon monoxide)

readings with the value given in Table 11-1. If this is higher, STOP

the boiler and call the Factory service department (see phone

number on the last cover page). Failure to comply with this

requirement could result in severe personal injury, death or

substantial property damage

Combustion Calibration

1. If it is not already present, create a combustion analysis probe site 8” after the flue gas

exhaust connection (see Figure 3-28, item “H”). To do so, follow the vent pipe

manufacturers’ instruction.

2. Keep the boiler or water heater in stand-by by pushing either button

(for water

heaters) or

(for boilers) until the word OFF is seen in the display.

3. Gain access to the Installer menu and set parameter 2010 to HIGH (see Section 5.4) so

the “Burner 1 (Master) will run for 20 minutes at high fire input, then generate a demand

for heat by pressing the

button.

4. Wait 2 to 3 minutes for the

CO

2

to stabilize;

5. Insert the probe of a calibrated combustion analyzer into the combustion analysis probe

“H” of Figure 3-28 and take a flue gas sample.

6. Compare the

CO

2

reading with the high fire range given in Table 4-1, making sure to use

the range for the gas type in use. If the

CO

2

reading is outside the specified range, it

must be adjusted using the “E” screw in Figure 4-2 of the gas valve closest to the burner

unit in fire. Use a 2.5mm Allen Wrench to turn the screw (clockwise to reduce the

CO

2

level, counter-clockwise to increase the

CO

2

level) in small increments and wait for the

CO

2

to stabilize to prevent overshooting the desired value.

Table 4-1: Combustion Calibration Values