5 specific vent and combustion air installations, Am series boilers and water heaters – AERCO AM Series Boiler User Manual User Manual

Page 63

AM Series Boilers and Water Heaters

CHAPTER 3 – INSTALLATION

OMM-0100_0B

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 63 of 156

GF-146

Ph.: 800-526-0288

PRI - 07/14/14

3.16.3 Min/Max Allowable Combustion Air and Vent Piping Lengths

The maximum length of the two pipes vent system is 120 equivalent feet (air intake plus flue

exhaust). However, each single pipe can’t be longer than 60 feet.

Each 45° elbow inserted in the venting system has a loss of pressure equivalent to 3 feet of

linear pipe

Each 90° elbow inserted in the venting system has a loss of pressure equivalent to 6 feet of

linear pipe.

The minimum length of the venting system is 1 foot (357 mm).

3.16.4 General Venting and Combustion Air Piping Installation

The unit must be vented and supplied with combustion and ventilation air as described in this

section. Ensure the vent and air piping and the combustion air supply comply with these

instructions regarding vent system, air system, and combustion air quality. Inspect finished vent

and air piping thoroughly to ensure all are airtight and comply with the instructions provided and

with all requirements of all applicable codes. Failure to provide a properly installed vent and air

system will cause severe personal injury or death.

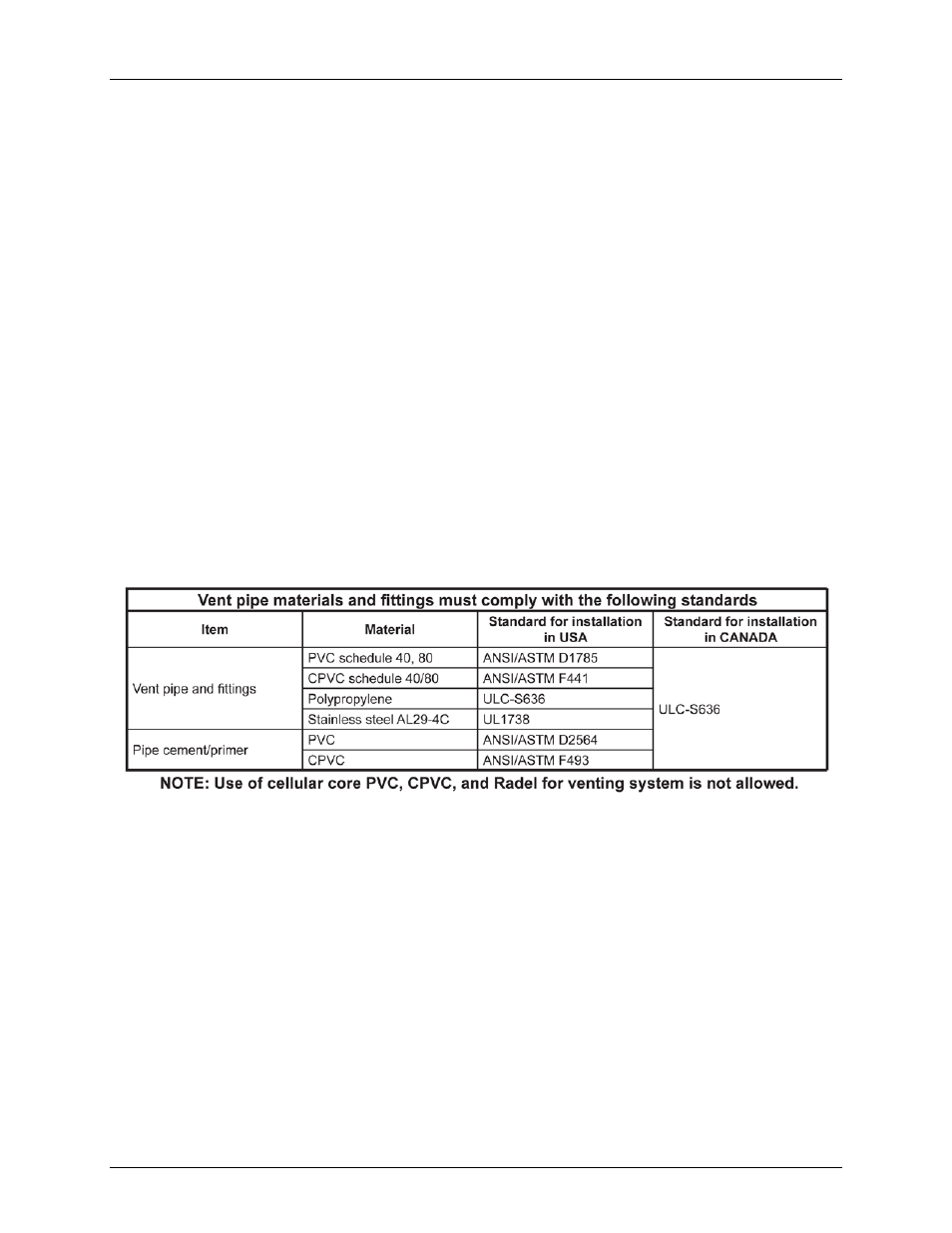

Using vent materials other than those listed in Table 3-3 and Table 3-4, failure to properly seal

all seams and joints, mixing of venting materials or failure to follow vent pipe and fittings

manufacturer’s instructions can result in injury, death or property damage.

Table 3-3: Approved Venting Materials

3.16.5 Specific Vent and Combustion Air Installations

The air inlet pipe(s) must be sealed. Improper sealed can result in excessive levels of carbon

monoxide.

Choose acceptable combustion air inlet pipe materials from the following list:

• PVC, CPVC or ABS

• AL29-4C, stainless steel material to be sealed to specification of its manufacturer.

• Polypropylene material to be sealed to specification of its manufacturer.

Using air intake materials other than those specified, mixing the specified materials, failure to

properly seal all seams and joints or failure to follow the manufacturer’s instructions can result in

flue gas recirculation, spillage of flue products and carbon monoxide emissions.