Cooling profile limitations, Profile designer test parameters – Cannon Instrument CMRV-4500 User Manual

Page 90

84

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 •

CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

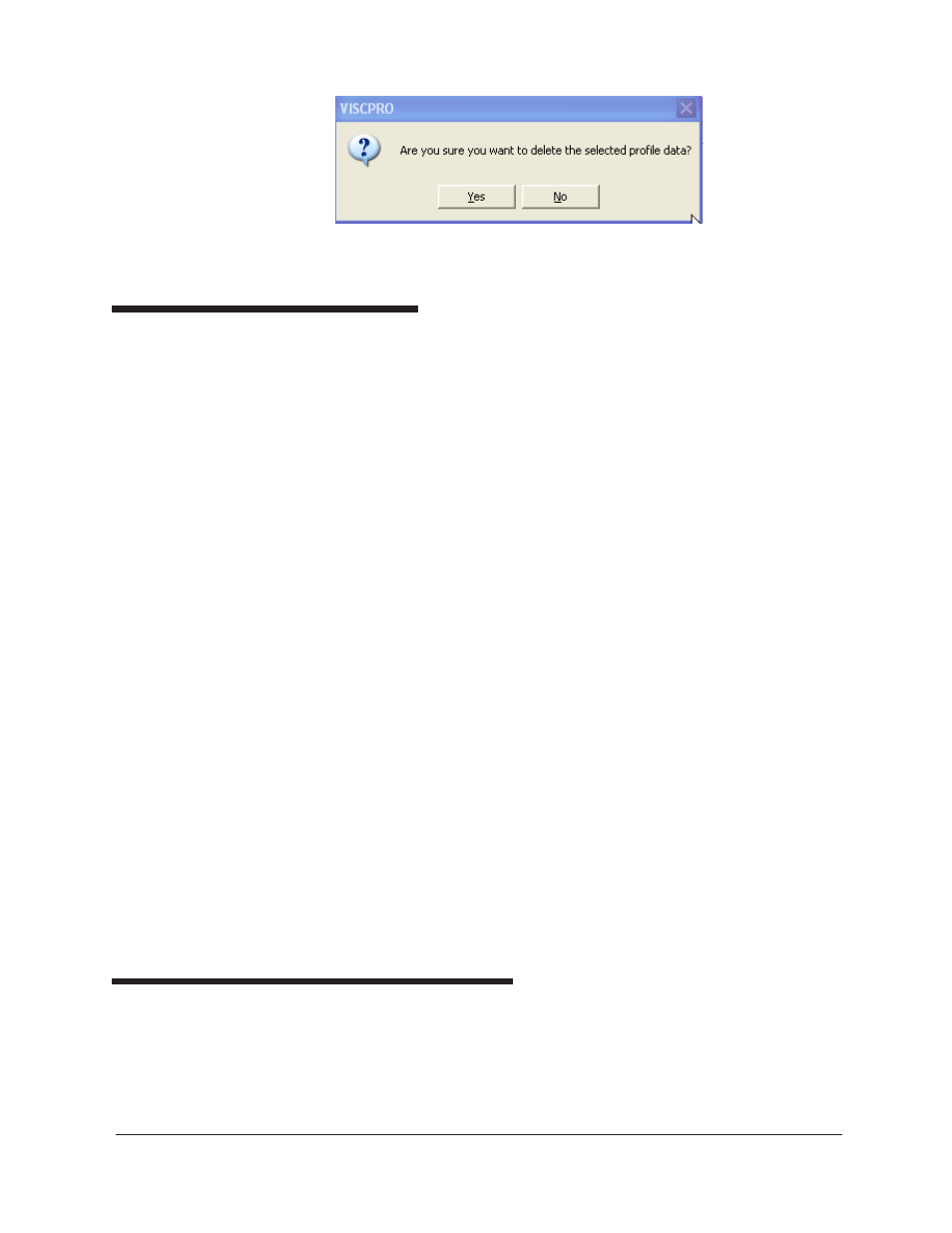

TO delete the point click

Yes

. To keep the selected point(s) click

No

.

Cooling profile limitations

CMRV cooling capacity

The CMRV cooling capacity changes proportionally with the temperature

at which the instrument is controlling. Greater cooling capacity is

achieved at warmer temperatures, and capacity decreases as temperature

decreases. This makes linear rates-of-cooling impossible in relatively

short time frames.

Correcting profiles

If the rate-of-cooling for a profile exceeds the cooling capacity of the

instrument, one of three things must be done:

Lengthen the time between the two fixed temperature points

Decrease the temperature change between the two fixed times

Apply a combination of the two previous options.

When a profile data point with a specified tolerance is entered in the

Profile Designer, software calculations are automatically made to deter-

mine if the rate-of-cooling relative to the previously-entered point is

within the instrument’s capability. It is assumed that the instrument can

achieve the temperature specified by the previous point. If no tolerance is

specified for that point, then this assumption may or may not be war-

ranted. For this reason, it is possible to design a profile that the instru-

ment is incapable of achieving. The software will only flag those points

that are absolutely impossible to realize. This suggests that experience

and experimentation are needed to properly design profiles which can be

run successfully.

NOTE

The ASTM D 3829 and ASTM D 4684 profiles supplied with the MRVW

software define non-toleranced points which are outside of the

instrument’s capability, but these are merely necessary stepping stones

which permit the instrument to attain proper temperature control at the

subsequent temperatures that are toleranced.

Profile Designer test parameters

The Profile Designer displays important test parameters for Yield Stress

and Viscosity testing. These values are editable from the Profile Editor.

For all ASTM profiles in the profile library, these values have been preset

in conformity with current ASTM specifications.