Measuring apparent viscosity – Cannon Instrument CMRV-4500 User Manual

Page 73

67

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 •

CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

10. If testing viscosity for the sample, follow the directions for viscosity

testing (see Measuring Apparent Viscosity, next page).

11. Repeat steps 1-10 to perform yield stress/viscosity tests for all

remaining cells to be tested in order from left to right.

Notes on yield stress testing

Step 9 (see previous section) is required for ASTM D 3829.

The ASTM D 4684 method is a pass-fail method for fresh oils. If the

rotor fails to move with the weight of the 10-gram hook-cage, the oil

has failed the test. However, the MRVW program permits adding of

additional weights. If this alternate method is preferred, continue with

the procedure as described in step 9. Otherwise, click the

Abort Test

button to abort yield stress testing on that cell.

NOTE

Do not abort CMRV temperature control until you have finished all yield

stress and viscosity tests for the cells.

Pulley-wheel motion is detected by the digital-optical sensor. Ad-

equate rotor movement is defined as 13° of rotation for ASTM D

4684 and ASTM D 6821 (This is equivalent to 3 mm of motion by

the crossarm). For ASTM D 3829, 10° of rotation is required.

If yield stress testing on a cell is aborted before adequate rotor

movement is detected, the resultant calculated yield stress will be

based on the highest weight used. For example, if the operator aborts

a yield stress calculation after testing with a total of 30 grams with no

rotor movement, the CMRV software will report yield stress greater

than 105 Pascals (Y>105).

Measuring apparent viscosity

After the yield stress test has concluded, you may measure apparent

viscosity using the procedure below:

1. Place the pulley-wheel in line with the appropriate viscometric cell

and place the rotor thread over the pulley-wheel.

NOTE

ASTM methodology requires testing the samples in sequence from left to

right.

2. Ensure that a Sample ID has been entered for each sample. Then

click

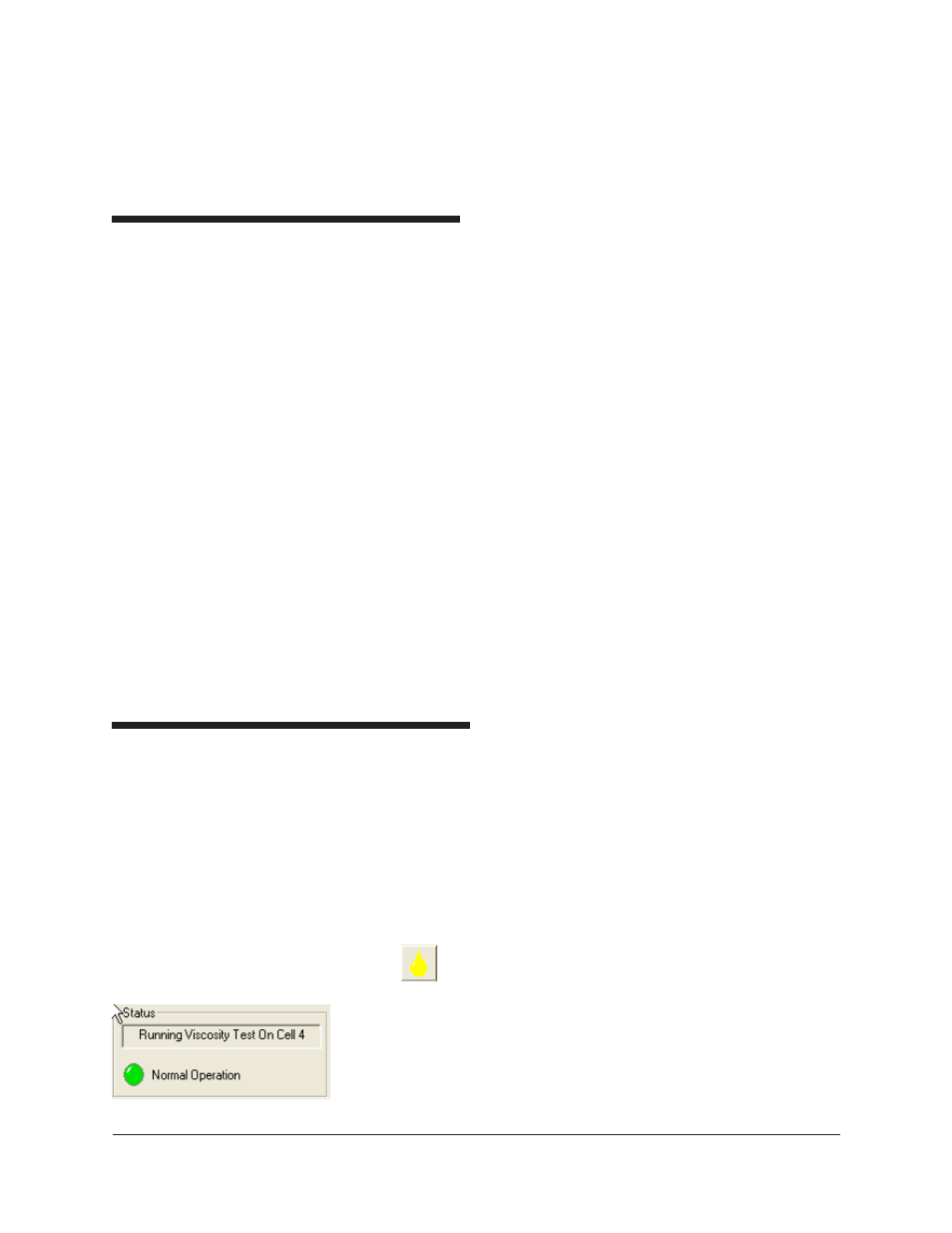

for the desired sample. OR use the

Tab

key to highlight

the desired viscosity test icon and then press

R. The

Viscosity

LED (light-emitting diode) on the CMRV-4500 will glow and the

Start Test

button will begin flashing rapidly.

3. Carefully place the large hook-weight on the end of the thread (see

photo, next page), supporting the weight with your hand to prevent

rotation of the rotor.