Cannon Instrument CMRV-4500 User Manual

Page 43

37

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 •

CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

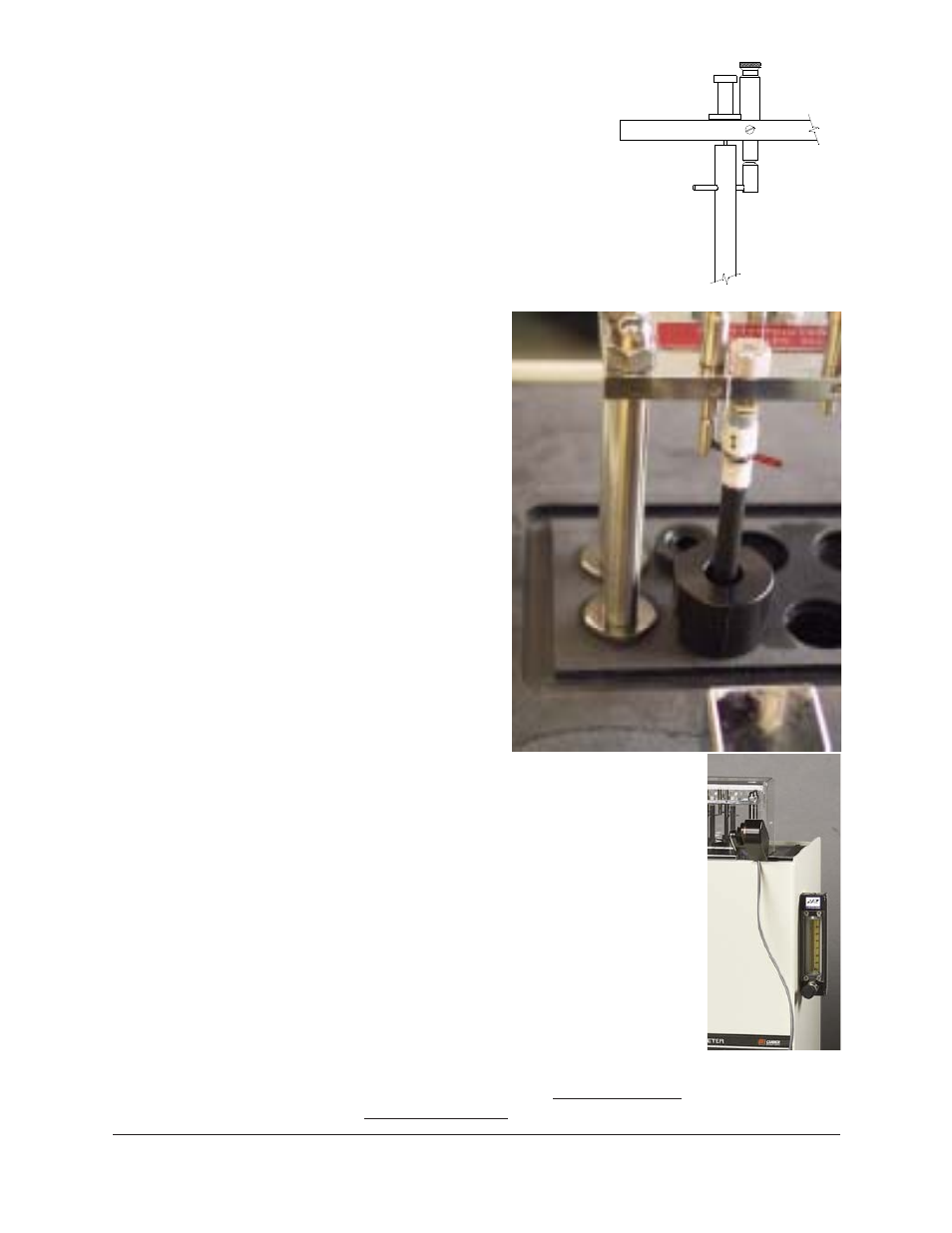

wound around the rotor shaft.

Then pass the thread below the

crossbar and continue turning the

rotor clockwise (as viewed from

above) to wind 20 closely spaced turns of

thread around the shaft below the crossbar

without overlapping the turns. About 200 mm

(8 inches) of thread will remain. Place this

remaining length of thread over the upper

bearing support plate so it hangs to the rear of

the viscometer

and secure the

rotor in place by

lowering the rotor

locking pin over

the rotor crossbar

(see figure and

photo). You may

need to turn the

rotor slightly to

align the crossbar

with the locking

pin.

8. Repeat steps 4-7

for each of the

remaining rotors/

cells.

Plexiglas

®

cover placement

9. Place the

Plexiglas

®

cover

in position over

the top of the

viscometric cells.

The small hole

which allows the -

46 to 30°C thermometer to extend through the

cover should be on the left when viewed from

the front of the viscometer.

10. CMRV users following the ASTM D 4684 or

ASTM D 3829 methodology should connect a

flexible 3/16"-OD tube from their dry gas

supply and regulator to the dry gas purge in the

Plexiglas

®

cover. The tubing may be removed,

along with the cover, prior to viscosity/yield

stress testing.

11. Whatever the methodology, the purge should

continue throughout the temperature profile

using dry gas at a flow rate between 20 and 30

milliliters per minute.

Wound rotor with cell

caps in place

CMRV with side-

mounted dry gas

purge