Brookfield DV3T Rheometer User Manual

Page 96

Brookfield Engineering Labs., Inc.

Page 96

Manual No. M13-2100

A.4 Verifying Calibration

1. Determine the appropriate sample volume. Refer to Table A-1 to determine the correct sample

volume required for the spindle to be utilized.

2. Select a Brookfield Viscosity Standard fluid that will give viscosity readings between 10% and

100% of full scale range. Refer to Appendix B for viscosity ranges of cone spindles.

Brookfield uses mineral oil viscosity standard fluids to calibrate Wells Brookfield Cone/Plate

Rheometers at the factory. Brookfield recommends that customers use mineral oil viscosity

standard fluids when you perform a calibration check.

If you decide to use a silicone viscosity standard fluid, do not use a fluid with a viscosity value

greater than 5000 cP with a Cone/Plate. Brookfield offers a complete range of mineral oil viscosity

standards suitable for use with Cone/Plates for viscosities above 5,000 cP or shear rates above

500 sec

-1

; see Table E-2 in Appendix E for a list of available fluids.

It is best to use a viscosity standard fluid that will be close to the maximum viscosity for a given

cone spindle/speed combination.

Example: DV3TLV Rheometer, Cone Spindle CPA-42Z, Brookfield Silicone Viscosity Standard

having a viscosity of 9.7 cP at 25°C

At 60 RPM, the full scale viscosity range is 10.0 cP. Thus, the Rheometer reading should be

97% torque and 9.7 cP viscosity ± 0.197 cP. The allowable error (±0.197 cP) is a combination

of Rheometer accuracy and fluid tolerance (refer to Interpretation of Calibration Test Results

in Appendix E).

3. With the motor off, remove the sample cup and place the viscosity standard fluid into the cup.

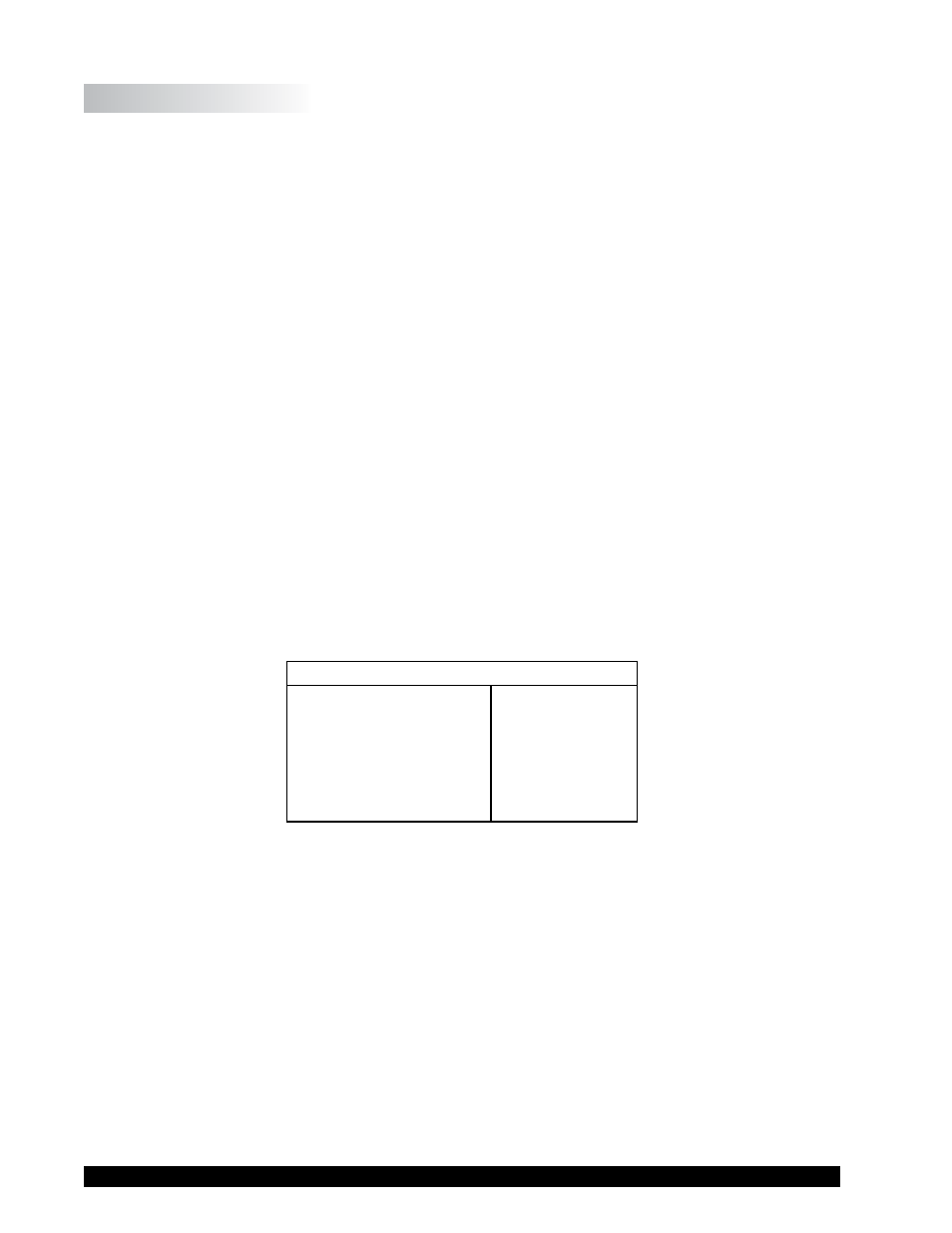

Table A-1

Cone Part No.

CPA-40Z, CPE-40, CP-40

CPA-41Z, CPE-41, CP-41

CPA-42Z, CPE-42, CP-42

CPA-51Z, CPE-51, CP-51

CPA-52Z, CPE-52, CP-52

Sample Volume

0.5 mL

2.0 mL

1.0 mL

0.5 mL

0.5 mL

4. Attach the sample cup to the Rheometer and allow sufficient time for the sample, cup and cone

to reach temperature equilibrium.

5. Turn the motor on. Set the desired speed(s). Measure the viscosity and record the reading in

both % torque and centipoise (cP).

6. Verify that the viscosity reading is within the allowable 1% deviation, as explained earlier, for

the specific viscosity standard fluid(s) that you are using.

The CPE or CPA designation on the cone spindle indicates use with Electronic Gap Setting Cone/

Plate Rheometers/Rheometers only.