Wiring (general), Wiring (master/slave), Wiring (general) 2 wiring (master/slave) – KMC Controls MEP-7800 Series User Manual

Page 2

MEP-7200/7500/7800 Series

2

Installation Guide

Wiring (Master/Slave)

See the

.

24 VAC/VDC

Power In

Feedback

Potentiometer

(MEP-7xx3 only)

24 VAC/VDC

Power In

24 VAC/VDC

Power In

2–10 VDC Control Signal

4–20 mA Control Signal

1–5 or 2–10 VDC Feedback Signal

Control Signal Common

(MEP-7x52 Only)

24 VAC/VDC

Power In

2

1

Switch/Contact

Jumper

Feedback

Potentiometer

(MEP-7xx3 only)

Feedback

Potentiometer

(MEP-7xx3 only)

CW

CCW

CW

CCW

1

2

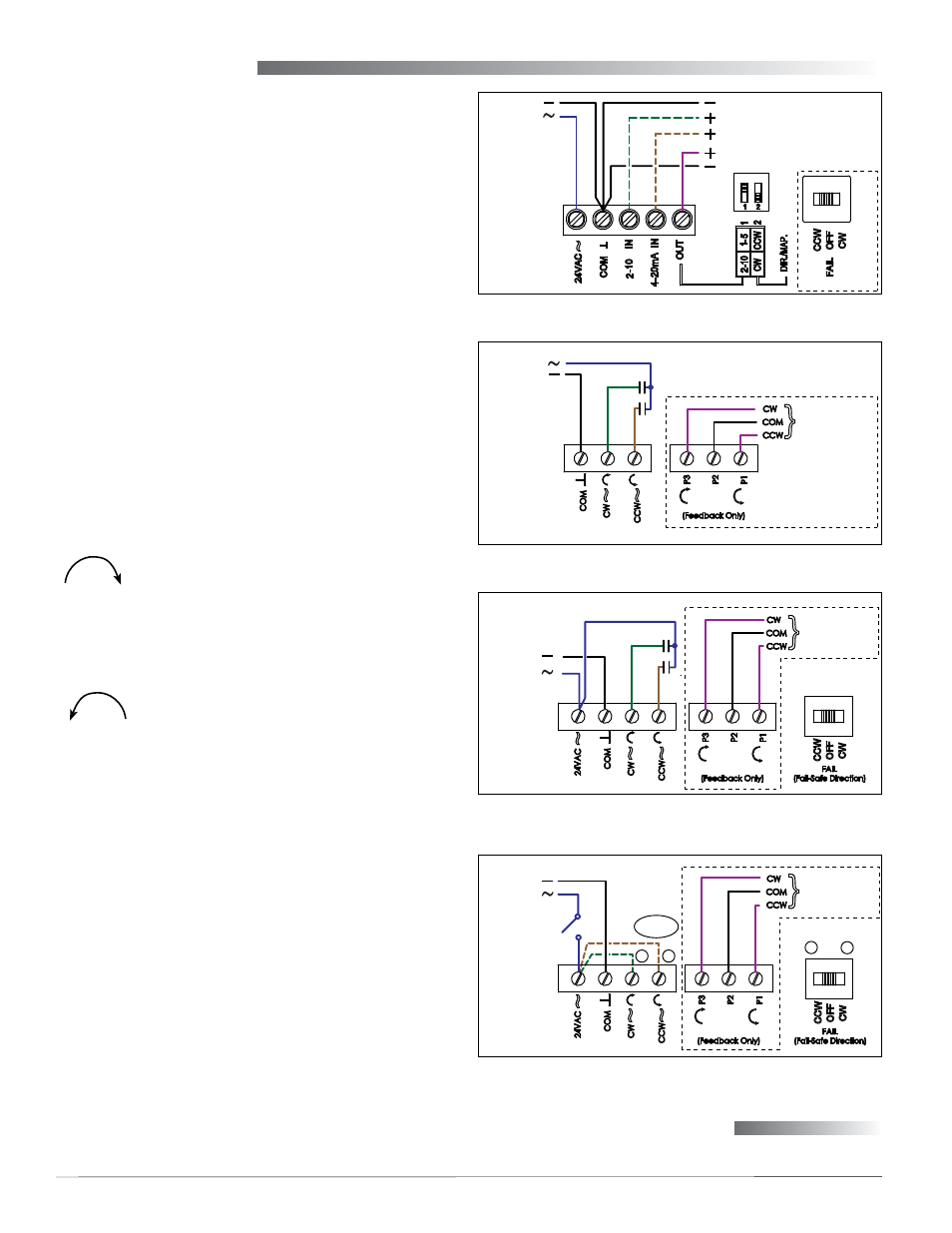

Illustration 2—MEP-7xx2 Wiring (Proportional)

Wiring (General)

1. Loosen the screws on the tethered access cover

and remove the cover.

2. Slide the conduit fitting plate out.

3. Using a utility knife or drill, cut the red plug

to accept wiring or replace the plug with an

application-specific fitting.

NOTE: The red plugs (or similar fittings) protect

the internal components from debris,

helping to ensure long actuator life.

4. Thread wires through the plugged opening and

connect to the terminal block according to the

appropriate model and options desired. (See

Illustrations 2 through 5.)

NOTE: For your convenience, the wiring terminal

block is removable.

NOTE: For

two-position wiring on a fail-safe tri-

state actuator (see Illustration 5), choose

one of these (jumpered) rotation options:

1. For clockwise rotation when the 24 volt

circuit switch/contact is closed, jumper

the 24 VAC terminal to the CW terminal

and select CCW on the Fail switch. When

the circuit opens, the actuator rotates

fully counterclockwise.

2. For

counterclockwise rotation when

the 24 volt circuit switch/contact is

closed, jumper the 24 VAC terminal to

the CCW terminal and select CW on the

Fail switch. When the switch opens, the

actuator rotates fully clockwise.

5. Reinstall the terminal block on the pins (if

removed) and the conduit fitting plate.

6. For MEP-7xx2 (proportional) models, adjust the

auto-mapping range reset, rotation direction,

and feedback voltage as needed. See

Feedback, & Auto-Mapping (Proportional MEP-

7. For MEP-7x5x models, adjust the fail-safe

(clockwise, counter-clockwise, or off) selector

switch, beside the terminal block, as needed.

NOTE: After initial connection or reconnection

to power (until the capacitors are fully

charged), fail-safe operation might be

delayed up to 20 seconds for the MEP-

725x/755x or up to 40 seconds for the MEP-

785x.

8. Reinstall the tethered cover and tighten the

screws.

Illustration 3—MEP-7x01/7x03 Wiring (Tri-State, Non-Fail-Safe)

Illustration 4—MEP-7x51/7x53 (Normal) Wiring

(Tri-State, Fail-Safe)

Illustration 5—MEP-7x51/7x53 Two-Position Wiring

(Tri-State, Fail-Safe)

24 VAC/VDC

Power In

Feedback

Potentiometer

(MEP-7xx3 only)

24 VAC/VDC

Power In

24 VAC/VDC

Power In

2–10 VDC Control Signal

4–20 mA Control Signal

1–5 or 2–10 VDC Feedback Signal

Control Signal Common

(MEP-7x52 Only)

24 VAC/VDC

Power In

2

1

Switch/Contact

Jumper

Feedback

Potentiometer

(MEP-7xx3 only)

Feedback

Potentiometer

(MEP-7xx3 only)

CW

CCW

CW

CCW

1

2